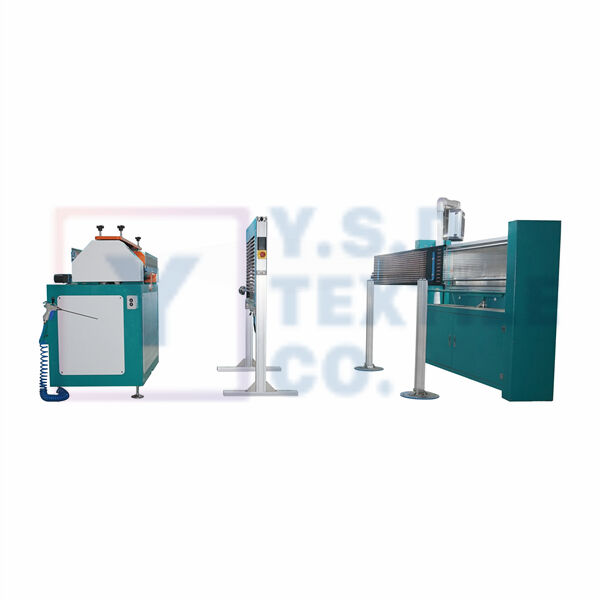

ProfixM is very excited to offer you the Karl Mayer Warping Machine! This one is a useful tool to produce wide variety of fabrics. Clothes, curtains and many more are what we make from fabrics. Today we are going to Read Full Story about this profixM karl mayer warping machine specification that How it Works and Why it is so Important for Textile Industry.

Karl Mayer Warping Machine – a machine which is used to make good quality yarn to made cloth fabrics. Colonial women often spun shallow, circular skeins of yarn Colonists followed these tight spirals and looped the result around the moving wheel colonists would tie this fluff tightly together. This machine comprises various parts that work together to pick and prepare the yarn, size it and then beaming ie. readying if for weaving output. Each component of the machine has to do its work just right to properly yarn it.

We can use The Karl Mayer Warping Machine also which makes good yarns for many different types of fabrics. It sets the yarn for weaving — in plain words, it ensures spinning if perfect according to each of the manufacturing steps needed to make fabric. This profixM karl mayer sectional warping machine is special as it helps to make sure that all yarns are resistant enough, looking nice and the final fabrics have a great cure.

It is another part of the machine for knitting and weaving which is known as Karl Mayer Warp-Knitting Solution. This will result in durable, stylish fabrics that will lower with expediency and consistency for long life. There are special tools that can enhance the quality and quantity of yarn produced by warping machine. This is what makes him able to produce amazing fabrics that are aesthetic but also created to last.

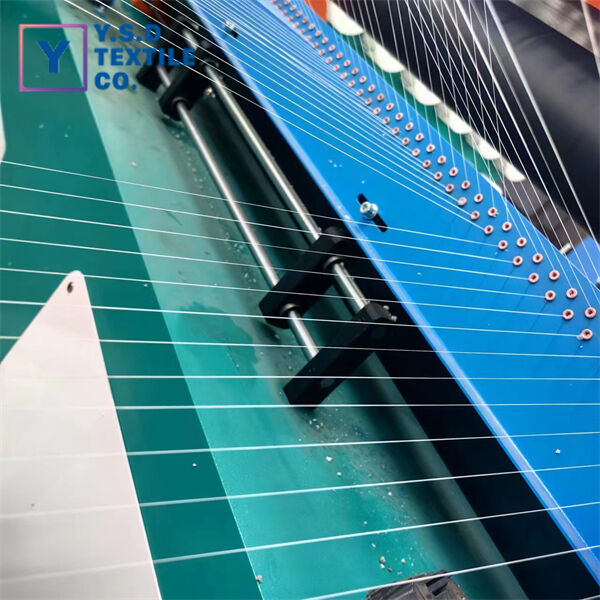

This smart technology-equipped device is made to perform better. One key element of the profixM karl mayer knitting machine is the so called creel. Typically, this is done with a special holder (creel) which holds enough spools or cones of yarn that it allows all the colors used in one color section of the fabric to be taken off at once without tangling them. Durable Carrying and Storage Tote, Will Allow You to Stack So Many Cones on Multiple Levels it is Sleek with High Holding Potential.

A second critical system is the tensioning system. This system manages the yarn tension so that it remains at an appropriate tightness level as it is rapidly passed through the machine. This is important to make sure that the yarn quality even (It looks the same all at once) and same color. That way, the end product looks excellent.

Which also comprises a sizing system? This system brings greater resistance and the yarn regains elasticity. Elasticity refers to the yarns ability to stretch a small amount prior breakage. This is significant because it allows the yarn to withstand the pulling and abrasion that will occur during the weaving without breaking.

products simple to install, set up Karl mayer warping machine.

company was founded in 2013. Over last eleven years, we've sold 300 sets Karl mayer warping machineand continue to be the top in terms of sales this day. Our business is a niche firm that designs, produces, sells split warping equipment and yarn. factory staff has knowledge expertise.

research and development department is the top quality. We have been providing yarn machines for more than 12 years. We keep up-grading technology. Additionally, we have 30,000m2 of machine production workshop and 20,000m2of nylon/ polyester production workshop.team Karl mayer warping machineto providing you with supreme quality machines. Every member the team is committed to their work and accountable their daily job. We truly hope that our expertise and technology will yield greater quality of work.

factory team is customer-focused organization and realizes that performance of an organization is dependent on happiness and needs of its customers. They are attentive to the opinionscustomers, optimize production and service satisfy their requirements and expectations.