Correctly Cutting Nylon and Polyester Yarn is KEY to Creating Clothing and Other Fabric Items After making different sizes of pieces we make sure that the yarn is the right size to use in these items. So, crucial weapon is split machine. In textile, we need the yarn to be made very fast and with accuracy. To make high speed sectional split warping machine more convenient, ProfixM has built a special split machine so that the yarn is divided evenly into parts.

In fact, plitting machines by profixM have become crucial in the textile sector because they save money and help workers work better. And before the invention of splitting machines, yarn had to be cut by hand. textile machinery spare parts was a lot of time consuming and difficult. Not to mention the fact that it was difficult to visually make sure you were cutting them at the same size, potentially impacting quality. Unequal yarn pieces can result in a badly looking and performing fabric.

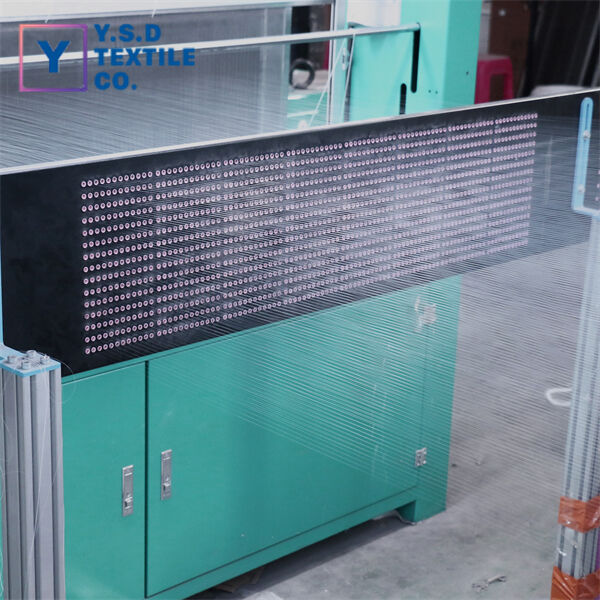

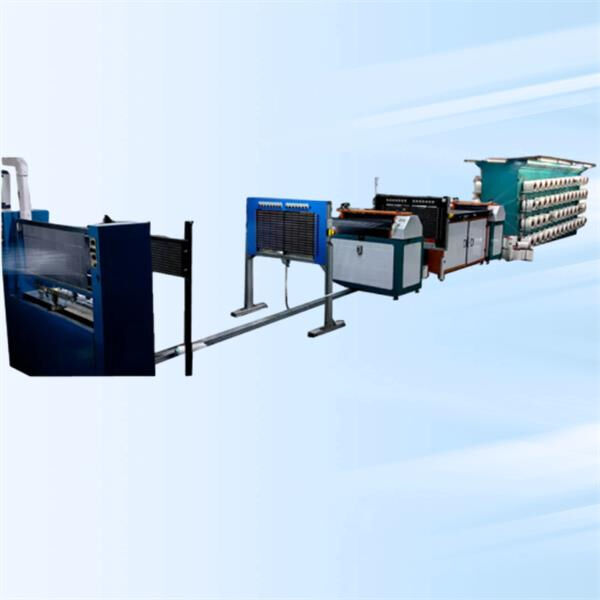

The split machine in ProfixM uses a round blade spinning around and cuts the yarn into thinner strips. This spinning is what helps create precise and consistent cuts. polyester monofilament is a universal machine that can handle various sizes of yarn and, therefore, fibers. This implies that whether the yarn is large or small, this splitting machine can manage it. When the machine operates at a high speed, it takes little time to cut more yarn. It will help factories to manufacture more number of products and this is very important for customer demands.

The patented technology in the ProfixM split machine also ensures that every cut is uniform in thickness. mother yarn warping split is a god-send because it stops issues with yarn quality. Final product consistency is enhanced when all the pieces are of equal size. The yarn can be tailored to any width using a machine that cuts the yarn at various lengths so that it suits your needs. This allows every product to be made to the same quality and high level, making every customer happy.

Another plus for the ProfixM split machine — it is easy to use It features clear buttons simple to use, a transparent screen that indicates the important information and how to operate direct warping machine step by step thanks the manual that comes in. Due to it being easy to use, even new employees can quickly learn to operate it without any struggle. The use of the machine can be more, especially when designers and tailors are involved in production- will enable textile industry to develop and expand creativity making excellent quality products.

have been providing yarn machines for more than 12 years. have top-quality research and development department. We constantly upgrade our Nylon polyester mother yarn split machine. Also, have a 20,000m2 nylon/polyester manufacturing workshop. staff is committed to supplying machines of the best quality. Every member the team is extremely dedicated and accountable for all of their job. We are confident that efforts and technology will result in more efficient productive work.

company was founded in year 2013. In the last eleven years, have sold over 300 sets of products and Nylon polyester mother yarn split machinethe leader in sales to day. Our company a specialist business that develops, manufactures, sells split warping equipment and yarn. team at our factory is skilled and knowledgeable.

products simple to set up, Nylon polyester mother yarn split machineuse.

Nylon polyester mother yarn split machineteam has always been customer-centric team, and they well aware that customer requirements satisfaction are crucial for the success of enterprise. They listen closely to the voices their customers, as well as optimise production and service satisfy their needs and expectations.