Woodworking can be a great hobby and something that many people feel passionate about but difficult to do. Section warp is a common issue that many woodworkers experience. Dishing: occurs when board is bent or twisted in various directions and making it difficult to work with. But don’t worry. However, you can fix this with some understanding and practice. Here we will be explaining about profixM section warp, and help you develop some good practices to minimize section warp in your woodworking projects. Wood suffers section warp when the condition of nature. If the wood dries unevenly, or there is stress in the wood fibers for example. This means that the wood could dry inconsistently, leading to warping. Section warp can also happen if the wood is not property stored or handled moving it around.

You must have seen it with all of us who choose a piece of wood for our project and do not notice if the section is suffering some inward warp. Examine the boards very carefully for bending or twisting. In case your board is warped, Hidden Woodworking will help you to straighten it out. You can apply pressure to the profixM section warping machine by doing this. You can also add some weights to keep it flat for a couple of days to get them straight. Proper Storage of Wood — Be sure to stack your wood in a dry and cool location. Do not put it in direct sunlight or near a source of heat as this can cause the wood to dry up too quickly and/or unevenly.

Sanding: Another surface preparation for eliminating any rough areas like dents. Take a coarse sandpaper and eliminate the bigger roughness first then use a milder one for an even finish. This is really going to add a lot of appeal for your woodworking project.

Bracing - Bracing is also a technique for reinforcing the board with additional support to prevent it from bending or twisting any further. You achieve this by adding more specifics to the profixM warp machine or yonder applying clamp pressure when ever placing the snowboard.

Resawing – This is a process where the board is sliced, sectioned, and glued back together to give you a flat board again. The approach that will be summarized here should only be used as a method of last resort because it is labor intensive and may result in some waste.

factory team extremely customer-centric and knows that success of business is dependent on needs and satisfaction of its clients. Customers are Section warplistened as well as production service are optimized meet customer expectations needs.

Section warpsimple set up, install use.

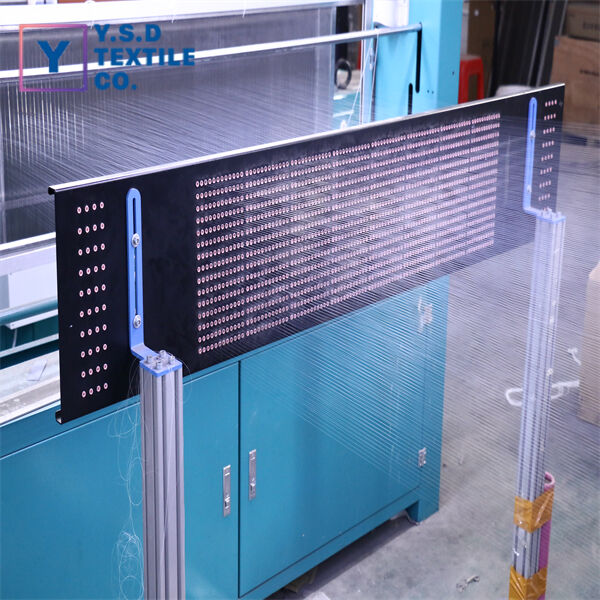

company was founded in 2013. Over last eleven years, we've sold 300 sets Section warpand continue to be the top in terms of sales this day. Our business is a niche firm that designs, produces, sells split warping equipment and yarn. factory staff has knowledge expertise.

have been providing yarn and machines more than 12 years. We have -quality research and development department. continuously upgrade our technology. also have a 20,000m2 nylon/polyester production workshop. team is dedicated to supplying machines that of the best quality. Each member of our team is on the job and Section warpfor all their job. truly hope that our expertise and technology will bring you a greater quality of work.