However, in the textile industry there is a section warping process. This procedure is used for forming a thing called warp beam. The role of a warp beam is quite crucial for it stores the yarn which will be woven later, into fabric. Warp Beam: Weaving fabric would not even be possible without the warp beam. Section warping is the process of breaking up the yarn into a number of small packages and winding them one after another onto a beam. Adjusting yarn tension to a greater extent for the weaver If you maintain better control over the yarn, your fabric can look more consistent and lovely.

What are the major advantages of using section warping in textiles? The one great thing: To assist the weavers in having more control over both the tightness of the yarn or rather tension and spacing of the separate individual pieces of yarn, along with ProfixM's product. The result is reconstructed cleaner, and more consistent fabrics. The splitting and warping machine of these sections also prevents tangling and breaking fabric yarn, saving time and labor. By reducing the chances of a tangled or broken yarn, weavers can finish off more fabric in short period which is good news.

Although, it is necessary to discuss some difficulties offered by section warping as well, as well as the from ProfixM. The main issue is that this can be an arduous task, especially when the weaver is working with intricate designs, as the process can be exceedingly time-consuming. Furthermore, the machines used for section warping can be very costly. These video shoots could be a problem for smaller textile companies not willing to spend such amounts of money into highly advanced technology.

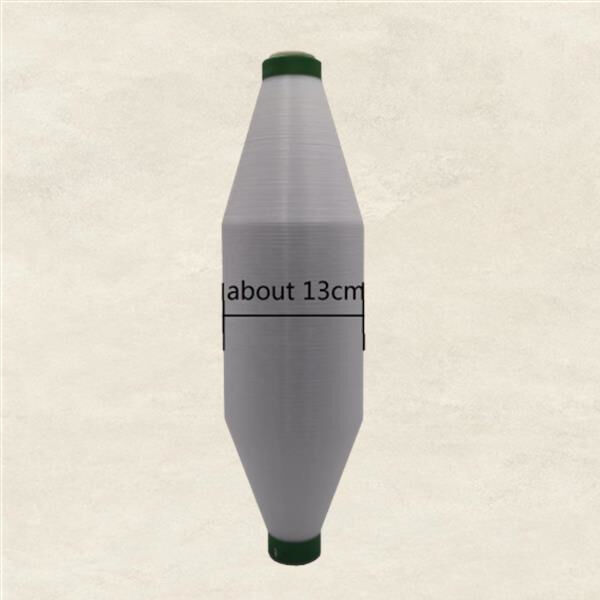

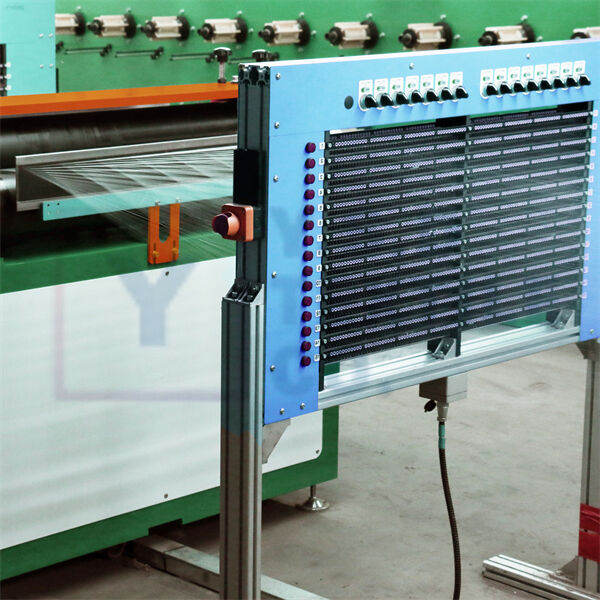

For improving section warping, some companies like ProfixM, are using advanced tools and techniques, identical to ProfixM's product. The yams are also divided into lengths, with the newer version of this part of the process is accomplished by using computer-driven machinery to cut each length accurately. This technology facilitates far greater precision and speed than the hand-warp methods traditionally used with yarn. It also makes special yarns for the section warping process. These produced results are ensured by the use of specialized yarns.

If mother yarn warping split machine is properly implemented, it can have a major impact on the efficiency and productivity of the textile industry. When weavers section the yarn before it winds on to the warp beam, numerous problems can be avoided, such as tangles and breaks. The end result of this is a reduction in downtime and waste [for companies that produce more fabric in less time] as well. It also means a more consistent end product for your customers, which often results in happier customers and less fabric being returned.

While splitting warping machine has many benefits to provide, it also comes burdened with several challenges for handicraft making companies. The first issue is the time consuming adjustment of tooling each new project. This is often a frustrating process. Nevertheless, this problem may be solved the machine of computerizsed section warping. Such machines can reduce setup times for the section warping operation and hence increase its precisions. Also careful with yarn breakages, as the more delicate or textured will break easily. Speciality yarns, which also control tension to avoid the breakage of the yarn, are used in section warping.

company was established in year 2013. We have sold 300 products over last 11 years and remain the market leader. Our company a highly skilled company that is involved in the design production, manufacture, and sale split warping machines and yarn. factory team has rich Section warpingskills and knowledge.

products Section warpingto install, set up operate.

research and development department is the top quality. We've been providing yarn machinery for over 12 years. We upgrade technology constantly. We also have huge 20,000m2 nylon/polyester Section warpingfacility. team is committed supplying machines of the highest quality. Every member of the team extremely dedicated and accountable for their daily task. We are hoping that our technology and dedication will allow you produce more effective work.

factory team has been customer-focused are aware that customer wants Section warpingis the key for the success of business. They pay attention their the voice customers and optimise production service to meet their expectations needs.