Textile-weaving machines use section warping technology, which is an effective solution for quickly and uniformly preparing numerous yarns together. This machine separates the yarn into sections instead of preparing all the yarn at once. With each of these sections, one can treat them one after the other to make sure that they are in position and have the necessary tension. Through this meticulous process comes a stretched and compact high-quality fabric without any defects or errors.

Having a good standard of quality and fast turnaround are extremely important requirements for success in the textile industry. These two objectives are possible when you use a section warping machine. By carefully aligning each section of yarn, manufacturers are able to create fabrics of higher quality and scale than previously possible.

So one of the beauties of the section warping machine is that it is able to handle virtually all types of yarn. These are the natural fibers such as wool and cotton, and synthetic fibers as polyester and nylon. This versatility allows the machine to be a key tool for textile manufacturers that need to respond to consumer preference, or to changing fashions in the marketplace.

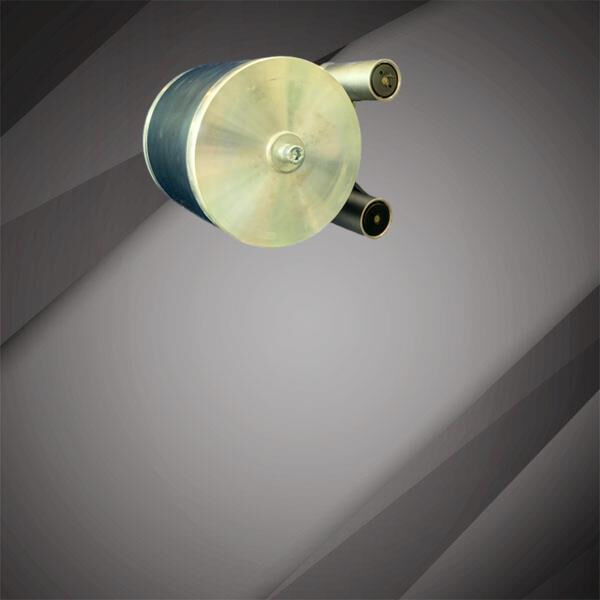

However the key to producing optimum yarn lies in the manner of sectional split warping machine. Each yarn receives a lot of care and close attention thanks to the ProfixM section warping machine. Such fine details produce a ready-made product that possesses supreme quality, and this is what every textile manufacturer craves for.

Modern section warping machines are highly efficient as well as versatile. With their ability to manage a variety of weaving techniques, manufacturers could now create intricate and novel types of fabrics. Different types of lines can be created, mother yarn on sectional direct warping machine from lightweight sheer fabrics all the way up to heavy-duty denim. Since numerous different types of fibers and wide variety techniques may be used, the potential for fabric design is limitless.

Section warping machine helps to reduce weaving cost and increase productivity — one of the biggest advantages. By setting up hundreds of yarns simultaneously and creating them more accurately, manufacturers can make textiles more rapidly and with less scrap. Using this method not only streamlines the production process but also saves costs, which can be passed on to the customer providing higher value products.

In addition, the ProfixM warping machine yarn is equipped with advanced features that can significantly increase the productivity. They include automation, real-time monitoring, and error detection. These tools enable operators to perform their work more efficiently and accurately, thus minimizing downtimes and improving the entire manufacturing process.

company was founded in 2013. have sold 300 products in last 11 years and are still the market leader. Our company a professional enterprise engaged in design production, Section warping machine, and sale of split warping machines as well as yarn. manufacturing team brimming with knowledge and expertise.

have been providing yarn and machines more than 12 years. We have -quality research and development department. continuously upgrade our technology. also have a 20,000m2 nylon/polyester production workshop. team is dedicated to supplying machines that of the best quality. Each member of our team is on the job and Section warping machinefor all their job. truly hope that our expertise and technology will bring you a greater quality of work.

Section warping machinesimple set up, install use.

manufacturing team has always been customer-focused, they are aware that customers' demands satisfaction are essential to growth of the enterprise. They actively listen to Section warping machineof customers optimize production service satisfy their needs and expectations.