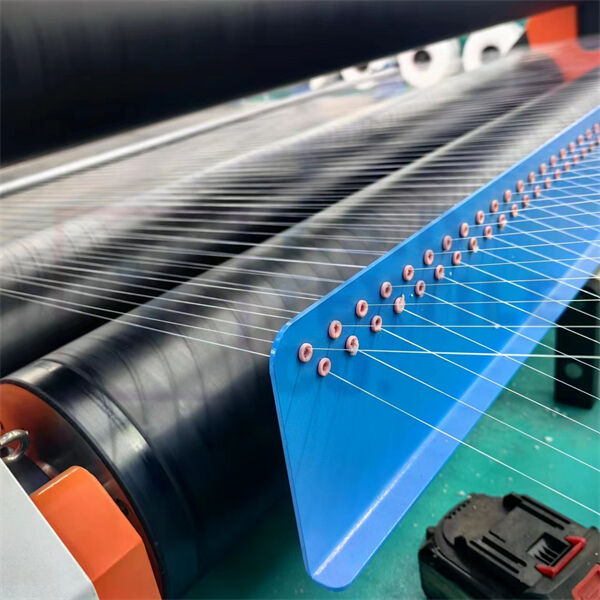

Do you like to sew? Maybe your passion is sewing clothes and creating quilts. Whatever you craft you always start with fabric. But how is fabric made? Making fabric means combining threads to weave together. Weaving: The process in which cloth is made by crossing threads over and under one another. Ever wonder how those threads end up in a loom for you to weave? The warping process (bottom left) used to be done by hand. And you can imagine dozens, hundreds, thousands of little tiny filaments and having done all by one person. This was a serious piece of work and it took ages to do — like, forever.

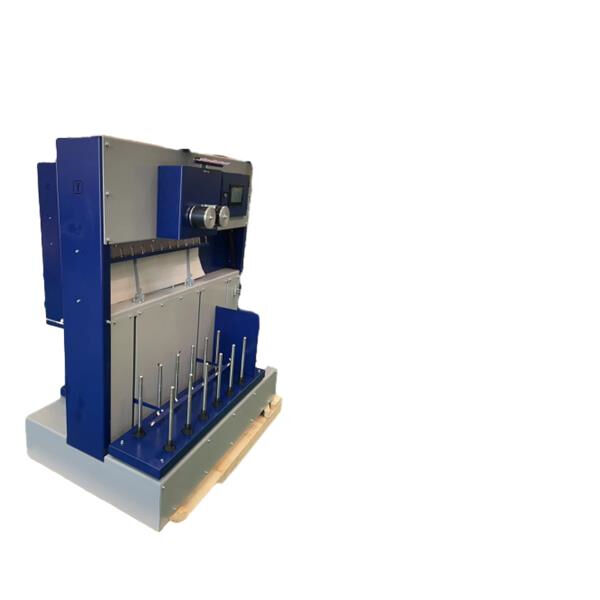

However, there is now an incredible device that can do it for you! This machine is known as a sectional warper. The roll beam sectional warper carries a lot of threads and puts them onto big rolls/spools. This is something akin to a large spool of thread used in the machine. That huge knot gets unraveled by the machine and wound up onto these spools. These cylindrical objects are known as profixM sectional warp beam, which is crucial in the sense that they get mounted on top of the weaving machine to weave a fabric.

One thing I have to say about using a sectional warper is it makes all the threads on the exact length!! By hand, often the threads can be a bit longer or shorter and this can make for hellish weaving. With the profixM sectional warping machine, all fillers are exactly right. What this means is that your fabric will look beautiful and top quality as all threads match perfectly.

What else section warper is amazing for it’s a swift working machine? And some range in the thousands of threads winds at a time (up to 2,000). Can you believe that? That means you can heavyweight a pile of fabric in no time at all. So, the more fabric you can get through your printer faster means the more stuff that you can sell and then make a bit of money for all that hard work. Therefore, if you use a sectional warper not only do they save time, but they can also help you make a living from something you love!

For example, if you would like your fabric to feature unique and intricate designs. That’s when you would get a high-speed sectional warper. A high speed sectional warper can be used to create designs that use multiple colors and yarn types. You can even do twills that draw and undraw as you weave! Sectional Warping– That is what makes a sectional warper unique compared to other warping machines. This technology allows you to make the most amazing and delicate images that will please everyone who sees your clothing.

Now you can get how beneficial sectional warper machine is, so now if you are also thinking to keep one of this machine in your manufacturing plant then will surely look for a good company that provides high-quality machines. Of course one of the best companies out there is ProfixM that manufacture profixM sectional warp. Not only are their machines reliable and easy to use, they also enable you to quickly and efficiently produce beautiful fabrics. On top, ProfixM is famous for its best customer support. You will never face a problem in your machine, so you can able to proceed your projects without difficulty.

company was established 2013. In the last 11 years, have sold 300 sets of products and the market leader in sales till today. Our company a specialist firm that designs, produces sells split-warping machines and yarn. Sectional warperstaff has practical skills and knowledge.

Sectional warperteam has always been customer-centric team, and they well aware that customer requirements satisfaction are crucial for the success of enterprise. They listen closely to the voices their customers, as well as optimise production and service satisfy their needs and expectations.

Sectional warpersimple set up, install use.

research and development department is the top quality. We've been providing yarn machinery for over 12 years. We upgrade technology constantly. We also have huge 20,000m2 nylon/polyester Sectional warperfacility. team is committed supplying machines of the highest quality. Every member of the team extremely dedicated and accountable for their daily task. We are hoping that our technology and dedication will allow you produce more effective work.