Textile machine by profixM factories are not new to our world. They were already being enjoyed three centuries ago, far back in the late 1700s. In those days, people started using machines to make cloth and all kinds of fabrics. And as technology advanced in subsequent years, workers were able to use these machines quickly and more easily. And even today, textile machine factories play very important role in the production of fabrics. sectional warping machine is just one of the ways that they contribute to achieve quick and efficient production of quality fabrics. Back in the day, textile machine factories need water or steam power to be able to run their machines. These were big machines that workers would use to spin yarn, weave fabric and dye so that beautiful textiles could be made. The machines were always extremely massive and required much attention to detail when attempting to maintain or fix them, but they also made the job significantly faster than if it had been done by hand. Due to this quick and effective method, machines like these were very soon welcomed by factory owners as well as workers.

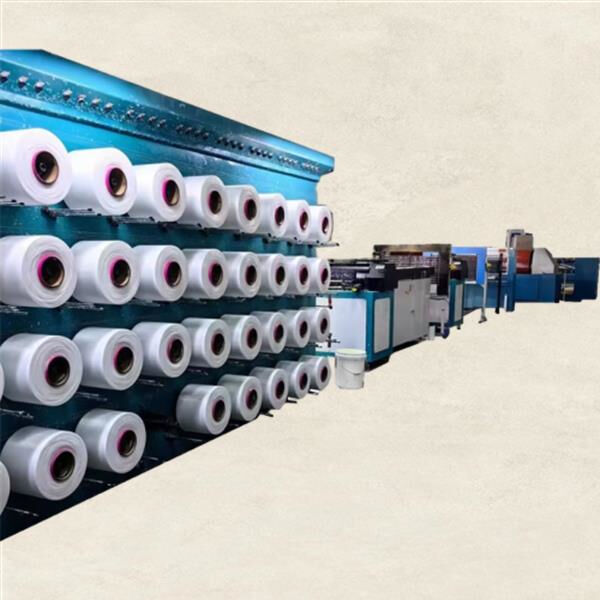

Todays Textile machines of profixM are highly advanced and sophisticated. polyester monofilament are formulated to create high-quality fabric at a fast pace with 100% efficiency. The landmark characteristic of contemporary textile machinery is the manner in which computer controls have been incorporated. Workers can make adjustments in how tight the fabric should be or how fast the machine should run with these special controls. Basically this allows the fabrics to be created very true so that higher quality is available for all. Other benefits of the current textile machines are that they are able to work with a variety of materials. These ones are designed to work through a range of clothing materials from the soft silks to heavy demin. This versatility allows textile factories to make a large selection of textiles hence offering the consumers with lots of options to choose from. These factories can work in several types of fabric and serve various markets and consumers.

High quality fabrics production in the textile machine factories by profixM is done using special systems. direct warping machine are organized in such a way that they fit well, which leads to the smooth operation of the whole production process. A factory might have equipment for spinning raw fibers into yarn, weaving that yarn into fabric, and dyeing the fabric. Every machine is streamlined to work in conjunction with one another, this keeps the project progressing smoothly.

In this fast-paced global village that never sleeps, perhaps the top priority for textile machine factories is to keep up with what people want. So imagine, for example, mother yarn warping split suddenly everyone wanted to buy something made out of a specific kind of fabric — they should be able to meet that demand and produce it, fast. So they can spend at some factories a lot of monies in new technology and send their workers to learn how to use this tech.

Yet automation is not without its troubles. textile machinery spare part may require specialized knowledge and expertise, and it can also be expensive. Some workers may also worry about being replaced by machines. In order to counter these fears, it is all the more crucial for textile factories to also invest in training their workers. The training will assist workers in securing fresh capabilities and realigning themselves to the evolving career outlook.

products simple to install, Textile machine factoryoperate.

company was established in year 2013. We have sold 300 products over last 11 years and remain the market leader. Our company a highly skilled company that is involved in the design production, manufacture, and sale split warping machines and yarn. factory team has rich Textile machine factoryskills and knowledge.

factory team is extremely customer-centric recognizes that the success a business is dependent on the needs satisfaction of its customers. They Textile machine factorylisten the voice of customers and enhance their service production in order satisfy their requirements and expectations.

have been providing yarn machines for more than 12 years. have top-quality research and development department. We constantly upgrade our Textile machine factory. Also, have a 20,000m2 nylon/polyester manufacturing workshop. staff is committed to supplying machines of the best quality. Every member the team is extremely dedicated and accountable for all of their job. We are confident that efforts and technology will result in more efficient productive work.