The textile warping machine is a major instrument for fabric fabrication. It helps in refining raw materials such as threads, fibers into exclusive designs that can be further utilized to make different type of cloths. We will also discuss then, how profixM warper textile machine for textiles works and why it is of immense importance since the time of discovery and till now?

Textiles are made up of yarns and the main purpose of a textile warping machine is for preparing the yarn. When we prepare yarn for weaving, we call it warping — this is when we wind the yarn onto a big beam (warp beam). It’s a Metal Beam which will hold the yarn as it winds at specific design. This is the way the warp beam pattern of what its fabric would look like. P The process has to be done with ultimate care as well as highly accurate so that the fabric designs come out exactly same as designed by manufacturers

The textile warping machine is a requirement to the fabric manufacturers for understanding the preparation of yarn in a best systematic way. These are high speed, accurate beam release machines. This high speed is the main asset to designers needs such as printing a same print in same fabric but also needing a print which will always be exactly similar. It allows fabric makers to save more time and minimize mistakes when making their fabric, making the process of creating a supply of fabric easier and quicker.

Warping could be the transformation from the design and style of fabric creating in a new era save worthy, along with makes the full applicable to additional lightweight weaving happens a lot quicker. Thanks to modern warping technologies, fabric manufacturers can now easily produce very detailed and intricate fabric with no issues. Consequently, profixM warper textile machine can output much larger quantities of fabric within the same duration. This saves them money, and allows fabric suppliers to provide their customers highest quality visually pleasing fabrics that have been engineered for a long life in the harshest of conditions.

While manufacturing any type of fabric, the basic role is played by Textile warping machine. Allowing fabric makers the option to create intricate and beautiful fabric so much faster, with a higher degree of precision but lord knows what it would take in blood, sweat, and tears with Years of labor without this profixM warper textile machine. This procedure of rapid prototyping textures helps the textile industry with making different textiles (cloths, home fabrics and so forth) in which we are living every day.

ProfixM is a well-known name of warping machines for textiles. They use state-of-the-art, high-tech machines that are way too advanced as compared to those used in past and this allows them to prepare even good fabrics but at a higher quantity. With the advent of this machine human beings who manufacture fabrics procure money rather than losing them, thus Profixm has changed the face of textile industry. A market that change so fast like todays the right approach is need some equipment to help you be more creative, agile and make time for your services.

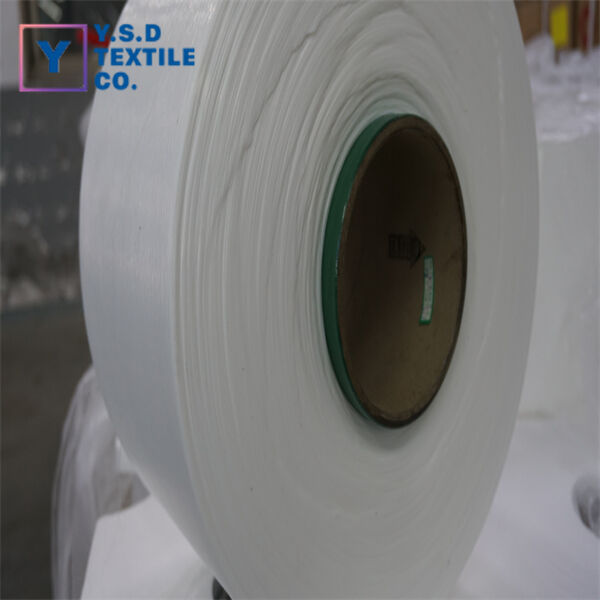

company was established 2013. Our Textile warping machinehas sold 300 products over the past 11 years, are the market most popular. company is a specialist company that designs, manufactures sells split-warping machines and yarn. manufacturing team brimming with practical skills and knowledge.

research and Textile warping machine team at our company is of best quality. We have provided yarn other equipment for over 12 years. We are constantly upgrading our technology. also have 30,000m2 machine production workshop and 20,000m2 nylon/polymer production workshop.Our team is committed providing you with supreme quality machines. Every member the team is extremely dedicated and accountable for all of their job. hope that our expertise and efforts will assist create more efficient work.

products Textile warping machineto install, set up operate.

factory team has been customer-focused are aware that customer wants Textile warping machineis the key for the success of business. They pay attention their the voice customers and optimise production service to meet their expectations needs.