Texturising yarn is a very fun and rewarding process of making special qualities yarns that we use for knitting and weaving. ProfixM: It can be called a company with vast knowledge regarding yarn Texturizing and various techniques to bring it into action. This ProfixM polyester textured yarns text is dedicated to what yarn Texturizing is, how many ways to deal with it and more importantly what are the new techniques we use for stronger and extraordinary yarn

Texturizing is transforming a yarn to be unique in its texture. There is a whole range of textures we can produce for different uses just by changing the way in which yarn is produced. It is a very vital process for knitting and weaving as it helps us in creating various types of clothing, fabric items which are widely used in day to day life.

Mechanically or Chemically: There are primarily two methods used to Texturize yarn, i. e., mechanically and chemically. Mechanical Texturizing is simply where we tug on, twist and pull the yarn by hand to give it texture. This is the method where we use our hands, with or without tools to create the effect that works for different styles of hairdos. Chemical Texturizing on the other hand employs special chemicals which alters strand at microscopic level. These chemicals change the structure of yarn so that it is textured and otherwise suitable for use in a range of applications

Other neat ways we Texturize yarn is by applying nanotechnogycljsurfacing it. With the help of such advanced technology, the yarn is made stronger and can withstand even harsh weather conditions or wear and tear. At ProfixM polyester textured yarn are constantly looking to evolve and improve upon our practices and methods to keep one step ahead of the industry.

Project for the design team is to join with scientists in crafting more patterns and colours in order of enriching the texture of yarns. We use new dyeing technology to maintain color vibrancy for longer-lasting yarns. Moreover, ProfixM polyester tex mono yarn center on producing merchandise in an eco-friendly way; this in turn bails us out save the earth.

The yarns produced by ProfixM come in many different types, each with its characteristics. They are made for a variety of crafts Our yarns can be soft, stretchy, strong, and easy to work with, which could adapt them to different projects in knitting and weaving. From chunky, to lace, and any weight in between you can be sure that we have the perfect yarn for your next sweater project or any other comfort you are imparting.

Through this Texturizing our yarn we can create different effects in yarn which may use in various fabrics as per its requirement. Soft, plush fabrics are best knit in a crinkly yarn while lightweight, airy fabrics are better suited to smooth yarn texture. This type is great for both knitters and weavers to match the yarn with what they are looking for.

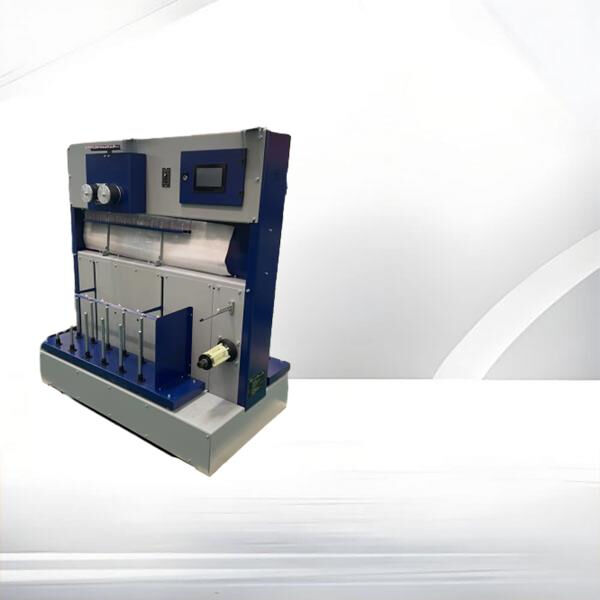

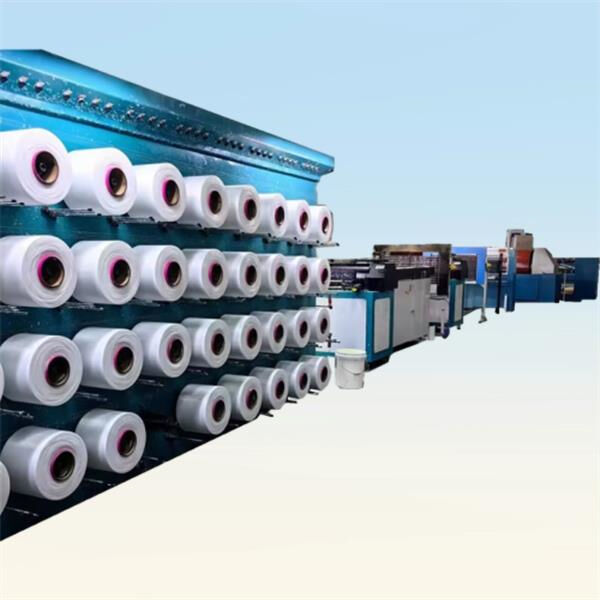

company was founded in year 2013. In the last eleven years, have sold over 300 sets of products and Yarn texturisingthe leader in sales to day. Our company a specialist business that develops, manufactures, sells split warping equipment and yarn. team at our factory is skilled and knowledgeable.

supply yarn and machine more than 12 years and are a top research development department. continue new Yarn texturisingupgrade. also have 30,000m2 of machine production workshop 20,000m2 of nylon/polymer production workshop.Our team is dedicated providing you with the highest quality machines. Every member our team is responsible for the work they do. We sincerely hope that our technology and efforts can help you achieve greater quality of work.

factory team has always been customer-centric team, they are well aware that Yarn texturisingrequirements satisfaction are crucial to the success of company. listen closely to the opinions of customers, optimize production and service meet their expectations and needs.

Yarn texturisingsimple set up, install use.