Texturising of yarn is a key process for the production of articles. At profixM, we recognise how the hands feel while blending in yarn is important as it improves the quality of end product. Problems are often encountered in the processes but there are solutions to these issues. Furthermore, yarn texturization has multiple advantages and can immensely enhance the quality of your products.

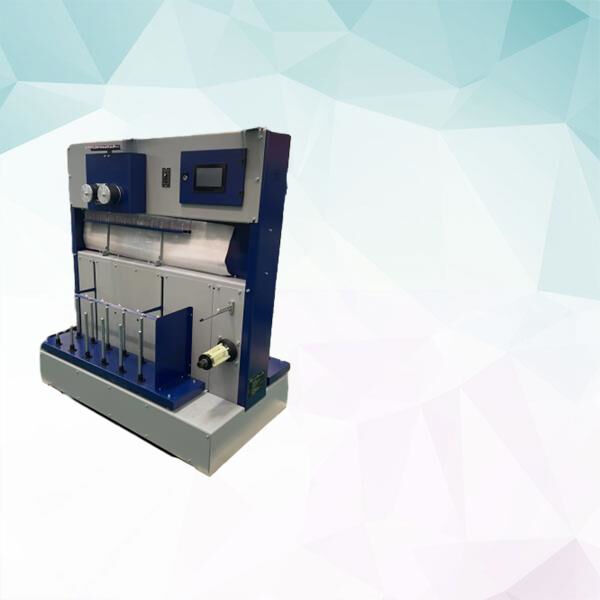

A general problem which has had to be coped with by producers during texturisation of yarn, is the case of non-uniform texturing in the fibre across the yarn. This may result in an inconsistent final product, for example, quality. This situation can be overcome by maintaining accuracy and repeatability in the texturizing operation. Through processes of monitoring and controlling the equipment, manufacturers can ensure that the yarn has a consistent texture, allowing for better finished products. Splitting machine

Another disadvantage encountered in the problems addressed is filament breakage during the texturizing operation. This can be due to causes such as incorrect tension or faults with the yarn. Regular maintenance as well as the use of good quality yarn material is essential to avoid breaking of yarn. By adjusting the tension settings and checking the proper functioning of the equipment, it is also possible to reduce yarn breaks and to enhance texturization performance.

Yarn texturizing provides an array of advantages for the manufacturers who want to improve their products. One of the primary advantages that come with enhanced softness and stretchiness of the yarn is greater comfort and durability in final products. Spinning textured carded yarn could enable manufacturers to produce fabrics for an array of uses such as clothing and home textiles.

Texturizing can provide not only better mechanical properties to the yarn, but also it could contribute positively in the appearance of final products. Textured yarns can form special patterns and effects in the fabric, bringing creativity and style to final product. This will enable manufacturers to distinguish their product offerings in a crowded marketplace and appeal to the increasing number of consumers seeking new, novel fashionable textiles.

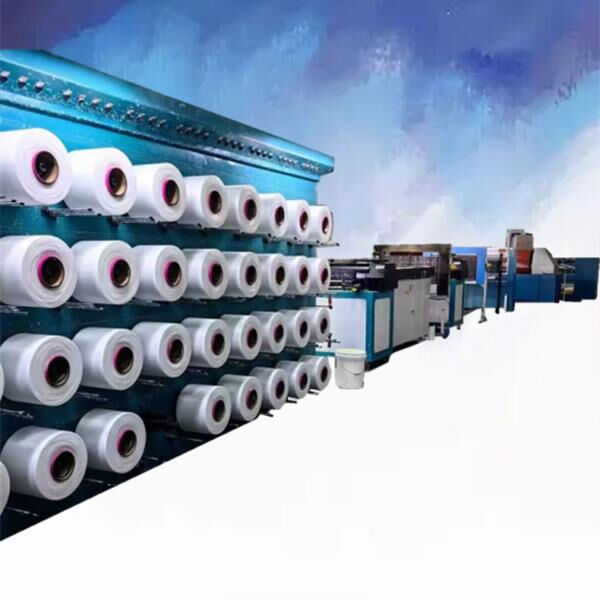

A recent development in the art of texturizing yarn is to utilize modern technological equipment or machines to produce complex textures and patterns within a yarn. Our state of the art machinery and techniques means I can provide a broader selection for your customers to enable all visual & texture options. Whether you need a plush, soft feel or a stronger more rugged finish with our team at profixM on hand we can do it all for you to get the most suitable yarn for your needs. Polyester DTY textured mono/ mother yarn

profixM knows that entering the world of yarn texturization is a daunting prospect – particularly if you’re new to the business. That’s why a team of experts is on hand to help guide you through the process, and give you the advice and support you need to run your business in an informed way. From which type of yarn to use, to what texturization considerations would work best for you, we’ve got you covered every step of the way.