PA6 nylon yarn is a kind of material to be used for powerful and durable fabrics. Did you ever reflect of how nylon yarn PA6 is made? So in this article, we will take a trip through the exciting process of manufacture of nylon yarn PA6 from raw materials to the basic unit of nylon fiber.

From raw material to Nylon yarn building block PA6 production

The former step to generate nylon yarn PA6, must possess the raw material. Step one of the process starts with caprolactam, a type of chemical compound that makes up 65-70% of the raw ingredient used to create PA6 nylon yarn. The distinction of caprolactam is the key to setting yarn nylon PA6 off from all others because the characteristics that account for its strength, durability, and versatility are based on this one building block.

The elaborate procedure of converting caprolactam into the premium quality nylon fibers

After collection, caprolactam is processed to produce high-quality nylon fibers. The process is a complex one that also requires a high level of precision to complete the necessary steps involved. The caprolactam is then heated and mixed with additional chemicals to start a chemical reaction, which creates long strands of nylon molecules. These are then spun into fibers that form the nylon yarn PA6.

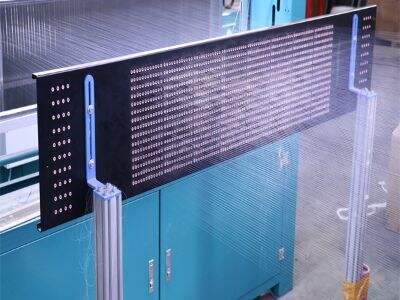

HdPE & Nylon YARN PA 6 Manufacturing Process

Caprolactam is the feedstock material to produce nylon yarn PA6, which is thermally polymerized and spun through a number of steam-heated, mechanically mixed, and hot-plasticized. Nylon fibers are then chemically reacted in the textbook: 1) The caprolactam is melted. A catalyst (chemical reaction helper) is added to promote the chemical reaction that will change the caprolactam molecules into nylon fiber emitting molecule called "propylene. This mixture is then brought to a certain temperature, which causes the nylon molecules to stick together and create long chains. The fibers of nylon are then spun in the form of yarn to fabricate nylon yarn PA6.

Chemical reactions and innovations in production.

Production of this type of yarn is based on complex chemical reactions and many solutions have been found through the passage of years. Since then, scientists and engineers have continued to work on the process to develop better means of producing nylon fibers. The better the production process and new innovation of nylon fiber technology comes from understanding chemical reactions which were performed for the manufacturing of nylon blend yarn PA6.

Using testing and manufacturing methods to guarantee prime performance and lasting functionality

To ensure that to live up this particular type of Nylon yarn PA6 to the top levels of performance and durability, it must be manufactured properly through a well established tested developed manufacturing methods for nylon. We are able to supply good quality, competitive price and best service for each batch of our PA6 nylon yarn is tested strictly in strength, stretch recovery performance inspections. Furthermore, the manufacturing methods are examined and modified often for creating PA6 nylon yarn with a standard that lasts longer and works better.

To sum it up, PA 6 nylon yarn is a very interesting in the way of making a product where caprolactam becomes premium quality fibre PA 6 nylon yarn by passing through various steps. We will serve that interest by exploring the chemical reactions and innovations that take place during its manufacture so, we can come to a greater knowledge of what nylon yarn PA6 is and appreciate all the resourceful testing an manufacturing it takes to guarantee its superior performance and durability. So the next time you come across any of the above nylon yarn PA6 woven fabric, then you would truly appreciate that piece for just what it is: a complex combination of compound to produce an extremely reliable and strong material.

Table of Contents

- From raw material to Nylon yarn building block PA6 production

- The elaborate procedure of converting caprolactam into the premium quality nylon fibers

- HdPE & Nylon YARN PA 6 Manufacturing Process

- Chemical reactions and innovations in production.

- Using testing and manufacturing methods to guarantee prime performance and lasting functionality

EN

EN

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

RO

RO

RU

RU

ES

ES

ID

ID

UK

UK

VI

VI

TH

TH

TR

TR

BN

BN

NE

NE