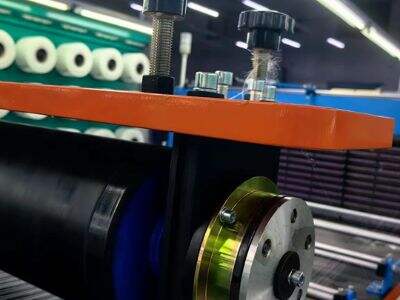

Textile machinery spare parts play vital components to retain our machines working smoothly. To ensure that these textile machinery spare parts have a long lifespan, we take care of our toys like this so they do not become old quickly, how we keep maintaining theses spare parts and make them durable similarly as well in this article, let discuss some of the easiest ways to do maintain and maximize their product cycle life time and cater our machines to run smoothly

You too, can clean and lubricate it regularly for best performance

In the same way, we clean up ourselves by bathing; textile machinery spare parts must also be cleaned often. The components can begin to have a layer of dirt and dust manifest, making them less efficient. To clean them, a soft cloth, or brush can be used to remove dirt wear on the surface gently. So when you are done cleaning, do not forget to oil these parts so that they keep on moving freely. Lubrication is included with the fittings to help minimize friction in areas where it leads to quicker wear and tear on parts. The spare parts runs for long time with effect of timely cleaning and greasing

But first, we have to address how fragile holders can be if not stored and handled correctly

We put them where we'd never damage them once the playtime is over. Just like others, you need to store your textile machinery spare parts properly. Set the spare parts in a clean, dry place where it can't roll around and won't be hit. As a result, this will help avoid any dents or scratches that would harm the parts' performance. Treat the spare parts gently and avoid accidents with them that may lead to damage in future. Proper storage and handling of the spare parts will help protect them and this will give you many more years of service

In spec work, and routine upkeep on wear and tear

Textile machinery spare parts should always be in regular check-ups much the same way as we visit our doctor for a regular health check-up. By examining the parts on a regular basis, you can identify any wear and tear, like cracks or rust. In case there are damages sustain during transport, replacement of these parts would be necessary to avoid a problematic operation. Taking care of worn out parts sooner rather than later can contribute to the life expectancy of the spare parts and that will in turn support your machines running well

Long lasting by using quality replacement parts

New toys(books) for the kids, we chose well made, durable ones that will last a long time. It holds good for textile machinery spare parts also, the quality spares ensure that they last long as well. Strong parts High-quality parts are manufactured to withstand more wear and tear than low-grade pieces. This will upgrade your machine and stop it from wearing out with you having to replace it again soon. Buying better parts save you not only time but money in the long run

Installation of Preventive Maintenance Schedule for Increased Lifespan

Preventive maintenance is planning certain activities on schedule to ensure everything works well. When you put a preventative maintenance schedule in place for your spare parts, this can help to extend the life of them and reduce any instances where they suffer unexpected breakdowns. Develop a preventive maintenance schedule for cleaning, lubrication, inspection and replacement of spare parts to be kept in good working order. Proactive maintenance will help keep your machines running preferable and trail blaze the applicable maintenance routines to prevent expensive downtime, repair or replacements. If you want to have your textile machinery spare parts last longer, you should perform maintenance on a regular basis

To sum up, caring for textile machinery spare parts is crucial to prolong their lifespan and ensuring smooth running of all the machines. Simple maintenance practices like regular cleaning and lubrication, storing and handling correctly, inspecting parts: condition and wear/tear of mechanical parts; then replacing them with high-quality replacement parts; by following a preventive scheduled maintenance plan will help keep spares in optimal working conditions as well as keeping our machines performing at their highest. Just as we care for our toys the same way here textile machinery spare parts are very important if you just want your machine to give services in a non-stop manner

Table of Contents

- You too, can clean and lubricate it regularly for best performance

- But first, we have to address how fragile holders can be if not stored and handled correctly

- In spec work, and routine upkeep on wear and tear

- Long lasting by using quality replacement parts

- Installation of Preventive Maintenance Schedule for Increased Lifespan

EN

EN

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

RO

RO

RU

RU

ES

ES

ID

ID

UK

UK

VI

VI

TH

TH

TR

TR

BN

BN

NE

NE