While creating the break between those gaskets and seals in production may seem like a small nit, it is one hell of an important step. Proper cutting is crucial to ensure these little parts do their job and and keep those things like liquids and gases from leaking out, in this article we will discuss why it is that important to get gaskets & seals cut just right during the manufacturing process.

Ensuring a tight seal

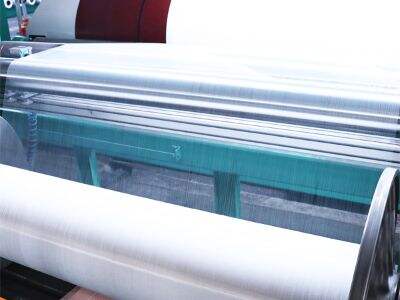

Manufacturers need to split fiber sheets with precision so that they can form a tight seal, which is absolutely important in the gasket and seal manufacturing process; Two part: Whenever two parts come nearer to each other with a gasket or seal in between, it needs to be totally compatible so that the properly fitting of the material happens. If it is too big or too small, then we have trouble covering all the costs: water and air leak from tiny holes. Flow control is used to ensure that either the machines function would be impacted or the liquids and gases are not mixed into other sections of a flow system. All of these issues can be easily prevented by simply cutting accurate gaskets and the proper seals to make sure everything works as it should.

Preventing leaks and contamination

Leakage and contamination are essential issues to prevent in gasket and seal manufacture for another reason. A nylon mono yarn gasket that is not cut properly cannot prevent liquids and gases from escaping. For example, the engine can drip oil or certain chemicals from a small pipe. Furthermore, if foreign matter such as dirt or dust infiltrates a system via a gap in the seal it has potential to be harmful and over time stuff might stop functioning. If we can ensure that gaskets and seals are separated correctly, then this problem is avoided in helping everything run smooth.

Maintaining structural integrity

Gaskets and Seals: Not just for fighting leaksGaskets and seals are more than just leak prevention devices; they also work to protect the structural stability of systems and machinery. When different parts come together, with a gasket or seal in between the two, it aids with lateral and horizontal movement of pressure so that everything stays put. If a gasket or seal has not been precisely cut, it will be unable to perform this duty. That nylon yarn pa6 means parts could move slightly or break when force is applied. If a gasket or seal is not cut properly this leads to insufficient fastening and equipment breaking down.

Enhancing product performance

This accurate splitting can also improve the performance of the gaskets and seals being produced. Each gasket and seal, properly cut flat works better sourceMappingURL=document=url This signifies that techniques will work to their whole probable and turn out higher results. The seals in the gaskets and how they are cut can be other examples of which influence this characteristic, such as a car engine that has properly cut gasket seals will have higher combustion efficiency and gasoline. When we pay attention to the smallest of details and properly separate gaskets & seals, it significantly enhances overall product performance and reliability.

Improving efficiency and durability

Lastly, gasket and seal manufacturing demands accurate splitting to increase longevity while saving time. Properly cut parts will last longer than those that are not and extend the life of other major components, such as gaskets and seals. And that means systems will be more reliable and with less downtime. Furthermore, the proper separation of gaskets and seals will prevent from having to make an expensive repair or replacement in the future. Greater precision in manufacture, means more efficient and durable products, saving us time and money down the line.

Conclusion

Fine cutting is required in gasket and seal making due to many reasons. Providing a perfect cut in gaskets and seals allows us to have an absolutely tight seal, avoiding leaks and contaminants; it also keeps the structural integrity of the product; increasing its operation, strength, life expectancy, performance and durability. We at ProfixM know that manufacturing needs to be precise, so we offer our customers high calibre gaskets and seals. The nylon mother yarn attention to detail we infuse in everything we do not only helps to ensure that products function as they are supposed to, but also ensures that they continue to work for years following purchase.

EN

EN

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

RO

RO

RU

RU

ES

ES

ID

ID

UK

UK

VI

VI

TH

TH

TR

TR

BN

BN

NE

NE