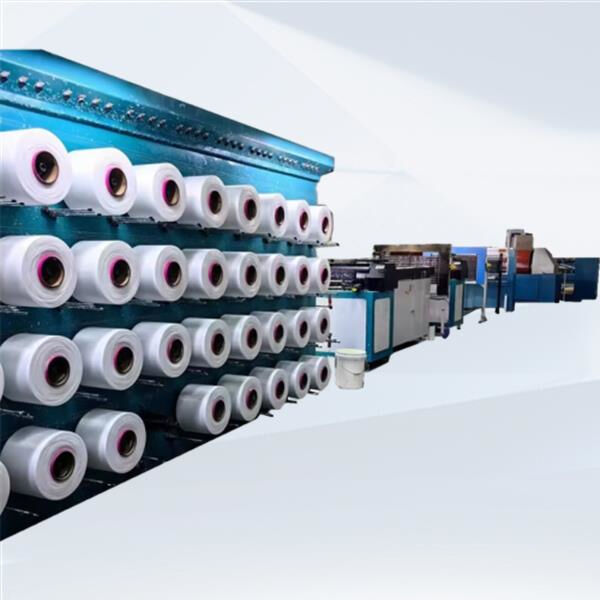

Das Labyrinth von Funden und Verlusten in Bezug auf die Herstellung unserer Kleidung ist heimtückisch, denn während wir sie tragen, verschwinden sie aus unserem Bewusstsein. Garn zu Stoff; alles, was wir in Form von Kleidungsstücken tragen, durchläuft eine lange und faszinierende Reise. Garn wird verwendet, um Stoffe herzustellen, und man kann mehr darüber lesen, aber heute sprechen wir über einen fortschrittlichen Typ von Garn, der als Mono-Garn bekannt ist. In einer Fabrik eines Mono-Garn-Anbieters und -Herstellungsunternehmens machten wir die sehr interessante Entdeckung, dass sowohl bei der Aufschnitt- als auch bei der Weberei umweltfreundlichere Maßnahmen viel detaillierter ergriffen werden können. Mono-Garn – Mono-Garn von profixM ist ein Faden, der aus nur einem Stück Plastik hergestellt wird. Viele weitere Faserstränge werden verdreht, um einen starken Faden zu bilden. polyester monofilament ist kein normales Garn, das vom Spindel abgewickelt wird. Mono-Garn wird auf eine bestimmte Weise und mit einer speziellen Maschine hergestellt, die sorgfältig bedient werden muss.

Folgende Prozesse unterziehen das Garn von profixM einer Kombination aus Behandlungen, die das Plastik im Wesentlichen verstärken und ästhetisch gestalten. Reiche Farben werden den Garnen hinzugefügt und jegliche Partikel entfernt; abschnitts-Warp-Maschine werden entweder übergezogen oder in Rahmen gedreht, die alle Arten von Kleidung zulassen, da sie gleich stark ist. Für den letzten (und wörtlichen) Schritt gehen wir in das Färberei. Hier bekommen wir die helleren Mono-Garnen. Färben: Garn, das aus der Endspinnerei kommt, wird in riesige Tanks voller Farbe getaucht und später zum Trocknen ausgelegt. Das noch langweilige weiße Garn wird blau, oder rot, oder gelb und grün... ich meine, die Liste lässt sich fortsetzen. Kompromisse - im Ernst, dieses Transformationsprozess zuzusehen ist eine der faszinierendsten Teile der Fabrikführung!

Nur ProfixM herstellt Monofilamentgarn von ProfixM über einen längeren Zeitraum, und unser hochwertiges Garn genießt großen Anklang auf dem Markt. Diese muttergarn Wicklungsspalt enthalten Etiketten für einige der bekanntesten Luxusmodemhäuser, wobei Mono-Garn verwendet wird, um Kleidung herzustellen. Mode ist schließlich ein großes Geschäft.

Der Markt zeigt einen Anstieg in der Nachfrage nach Mono-Garn, und um dieser Nachfrage gerecht zu werden, hat ProfixM eine weitere Fabrik an einem anderen Standort eröffnet und auch neue Technologien zur Vereinfachung und Beschleunigung des Produktionsprozesses erworben. Damit direkte Warp-Maschine mehr Haare produzieren kann, um die Bedürfnisse ihrer Kunden zu decken.

Das ist in der Mono-Garn-Fabrik von ProfixM und all die Arbeit, die ersatzteile für Textilmaschinen in die Herstellung dieses Materials investiert werden, macht es so wertvoll. Nun ist der Prozess, wie Mono-Garn hergestellt wird, ziemlich faszinierend, und wir haben durch verschiedene Innovationen unseren Weg verbessert, um diesen Prozess noch einfacher zu gestalten.

das Fabrikteam war immer ein kundenorientiertes Team, sie wissen genau, dass die Erfüllung der Anforderungen an Mono-Garn-Fabriken entscheidend für den Erfolg des Unternehmens ist. Sie hören aufmerksam auf die Meinungen der Kunden und optimieren Produktion und Service, um deren Erwartungen und Bedürfnisse zu erfüllen.

Einfache Einrichtung, Installation und Benutzung der Mono-Garn-Fabrik.

das Unternehmen wurde 2013 gegründet. In den letzten elf Jahren haben wir 300 Sets der Mono-Garn-Fabrik verkauft und bleiben weiterhin Spitze in Bezug auf Verkäufe bis heute. Unser Unternehmen ist ein Nischenunternehmen, das Split-Warping-Ausrüstungen und Garn herstellt, entwirft und verkauft. Das Fabrikpersonal besitzt Fachwissen und Expertise.

lieferung von Garn und Maschinen seit über 12 Jahren und verfügen über eine Spitzenforschungsabteilung. Fortsetzung des Upgrades der neuen Mono-Garnfabrik. Wir haben auch eine 30.000m2 große Maschinenproduktionswerkstatt und eine 20.000m2 große Nylon/Polymer-Produktionswerkstatt. Unser Team ist daraufhin ausgerichtet, Ihnen Maschinen höchster Qualität bereitzustellen. Jedes Mitglied unseres Teams ist für seine Arbeit verantwortlich. Wir hoffen aufrichtig, dass unsere Technologie und Bemühungen Ihnen helfen, eine noch bessere Arbeitsqualität zu erreichen.