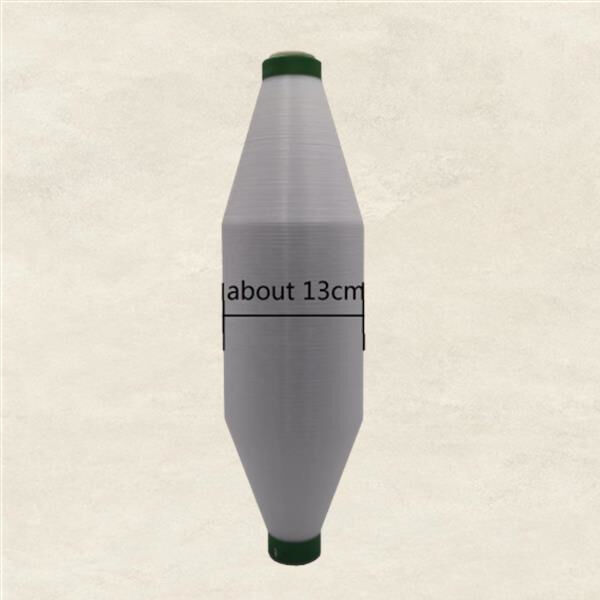

Cependant, dans l'industrie textile, il existe un processus appelé filature par sections. Cette procédure est utilisée pour former ce qu'on appelle le tambour à fils. Le rôle du tambour à fils est assez crucial car il stocke les fils qui seront tissés ultérieurement en tissu. Tambour à fils : Il serait même impossible de tisser du tissu sans le tambour à fils. La filature par sections consiste à diviser les fils en un certain nombre de petits paquets et à les enrouler un après l'autre sur un tambour. Ajuster la tension des fils dans une plus grande mesure pour le tisseur. Si vous maintenez un meilleur contrôle sur les fils, votre tissu peut paraître plus homogène et agréable.

Quels sont les principaux avantages de l'utilisation de la filature par sections dans les textiles ? Une chose importante : Aider les tisseurs à avoir plus de contrôle sur la tension ou plutôt la serrage des fils ainsi que leur espacement individuel, en association avec le produit ProfixM. Le résultat est un tissu reconstitué plus propre et plus constant. machine de dévidage et de préparation de ces sections empêche également l'enchevêtrement et la casse des fils du tissu, ce qui économise du temps et de la main-d'œuvre. En réduisant les risques d'un fil emmêlé ou cassé, les tisserands peuvent produire plus de tissu en peu de temps, ce qui est une bonne nouvelle.

Cependant, il est nécessaire de discuter de certaines difficultés posées par l'enroulement par section, ainsi que celles provenant de ProfixM. Le principal problème est que cela peut être une tâche ardue, surtout lorsque le tisseur travaille avec des conceptions complexes, car le processus peut être extrêmement chronophage. De plus, les machines utilisées pour l'enroulement par section peuvent être très coûteuses. Ces investissements peuvent poser problème pour les petites entreprises textiles non disposées à dépenser de telles sommes dans des technologies très avancées.

Pour améliorer le filage par sections, certaines entreprises comme ProfixM utilisent des outils et techniques avancés, identiques à ceux du produit ProfixM. Les fils sont également divisés en longueurs, avec la version plus récente de cette partie du processus réalisée grâce à des machines pilotées par ordinateur pour couper chaque longueur avec précision. Cette technologie permet une bien plus grande précision et rapidité que les méthodes traditionnelles de filage manuel utilisées avec les fils. Elle produit également des fils spéciaux pour le processus de filage par sections. Les résultats obtenus sont garantis par l'utilisation de fils spécialisés.

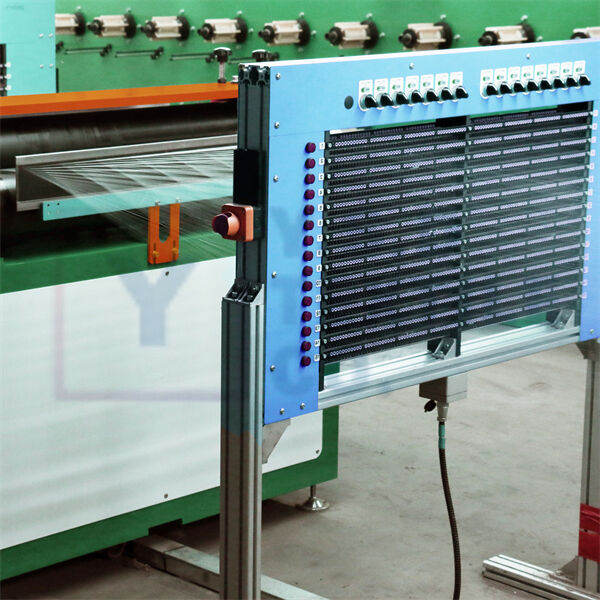

Si machine de dévidage divisé pour fil mère lorsqu'il est correctement mis en œuvre, il peut avoir un impact majeur sur l'efficacité et la productivité de l'industrie textile. Lorsque les tisserands sectionnent la fils avant qu'il ne s'enroule sur le rouleau de chaîne, de nombreux problèmes peuvent être évités, tels que les emmêlements et les cassures. Le résultat final est une réduction du temps d'arrêt et des déchets [pour les entreprises qui produisent plus de tissu en moins de temps] également. Cela signifie également un produit final plus homogène pour vos clients, ce qui entraîne souvent des clients plus satisfaits et moins de tissu retourné.

Pendant que machine à division et à enroulement apporte de nombreux avantages, mais présente également plusieurs défis pour les entreprises fabriquant des objets artisanaux. Le premier problème est le temps consacré aux ajustements d'outillage pour chaque nouveau projet. C'est souvent un processus frustrant. Néanmoins, ce problème peut être résolu par l'utilisation de machines à section d'enroulement informatisées. De telles machines peuvent réduire les temps de préparation pour l'opération de section d'enroulement et ainsi en augmenter la précision. Faites aussi attention aux cassures de fil, car les fils plus délicats ou texturés se cassent facilement. Des fils spéciaux, qui contrôlent également la tension pour éviter la rupture du fil, sont utilisés dans la section d'enroulement.

l'entreprise a été fondée en 2013. Nous avons vendu 300 produits au cours des 11 dernières années et restons le leader du marché. Notre entreprise est hautement qualifiée et est impliquée dans la conception, la production, la fabrication et la vente de machines d'enroulement sectionnel et de fil. L'équipe de l'usine possède des compétences et des connaissances riches en enroulement sectionnel.

produits d'enroulement sectionnel à installer, configurer et opérer.

le département de recherche et développement assure une qualité supérieure. Nous fournissons des machines à fil depuis plus de 12 ans. Nous mettons constamment à jour notre technologie. Nous disposons également d'une installation d'enroulement sectionnel en nylon/polyester de 20 000 m². L'équipe s'engage à fournir des machines de la plus haute qualité. Chaque membre de l'équipe est extrêmement dévoué et responsable de sa tâche quotidienne. Nous espérons que notre technologie et notre dévouement vous permettront de réaliser un travail plus efficace.

l'équipe d'usine qui se concentre sur la satisfaction des clients sait que le client souhaite que l'enroulement par section est la clé du succès de l'entreprise. Ils prêtent attention à la voix des clients et optimisent le service de production pour répondre à leurs attentes et besoins.