Filament texturé, dites-vous ? L'un d'entre eux est un type unique de matériau avec lequel un consommateur peut réaliser des impressions 3D, et il a gagné une incroyable popularité ces dernières années. Aujourd'hui, nous allons vous dire tout ce qu'il y a à savoir sur un filament textile, comment il fonctionne et certaines des choses incroyables qui ont été faites en l'utilisant. Après avoir lu ce texte, lorsque vous aurez terminé, pour ainsi dire, vous comprendrez mieux à quoi sert le texturé et pourquoi il est intéressant. C'est un plastique avec un retour tactile sur la surface du filament texturé. Cela lui donne une sensation différente au toucher, par rapport au plastique ordinaire. Il existe une variété de motifs et de styles pour les filaments texturés, y compris le bois, la pierre et le métal brillant. Ce ProfixM fils polyesters texturés l'entrée donnera à l'impression 3D finale une apparence réaliste et amusante à regarder. Son filament texturé est exactement ce qu'il vous faut pour imprimer quelque chose qui semble être du bois ou de la pierre réelle.

Il s'agit d'un mythe courant que le filament texturé ne sert qu'à rendre les impressions jolies, mais en réalité, il ouvre de nouvelles possibilités d'utilisation de l'impression 3D. Vous pouvez créer des objets qui procurent une sensation agréable au toucher, grâce au bon matériau et à une conception appropriée. Par exemple, on peut imprimer un manche d'outil avec un filament texturé rugueux. Cette texture peut également aider les gens à mieux saisir l'outil, facilitant son utilisation plutôt que de simplement le laisser tomber. Le filament texturé donnera également un meilleur aspect à vos impressions. Ce ProfixM fils polyester texturé donne un peu plus de caractère à l'impression pour la rendre vraiment intéressante à regarder. Un problème populaire avec l'impression 3D est celui des lignes de couches ou des coutures visibles dans l'impression finale. En réalité, lorsque vous imprimez avec un filament texturé, ces lignes de couches disparaissent presque entièrement, donnant l'impression que votre impression a été sablée jusqu'à être lisse comme du verre.

Le filament texturé peut encore améliorer la réalisme de leur apparence. Par exemple, si vous utilisez une texture de bois ou de pierre, cela rendra ensuite un modèle de maison ou de statue plus proche du bois et de la pierre réels. Aller dans ce ProfixM fil en nylon texturé jusqu'à ce niveau de détail peut être très impressionnant et cela fera certainement que vos projets se distinguent.

Dans le monde de l'impression 3D, l'introduction du filament texturé est un développement enthousiasmant. Les progrès de la technologie signifient qu'il est possible d'imprimer presque n'importe quoi en 3D avec un très haut degré de détail et de précision. Étant donné que les gens recherchent des impressions plus originales et de meilleure qualité, la demande de filaments texturés n'a jamais été aussi élevée parmi les concepteurs et créateurs.

Le filament texturé présente également un intérêt considérable — les irrégularités peuvent être utilisées à diverses fins. Leurs usages peuvent aller des conceptions esthétiques qui plaisent à l'œil, aux pièces fonctionnelles et destinées à une utilisation quotidienne. Un fini texturé sera également inclus dans l'ensemble, améliorant à la fois l'apparence et les performances finales pour une expérience globale meilleure.

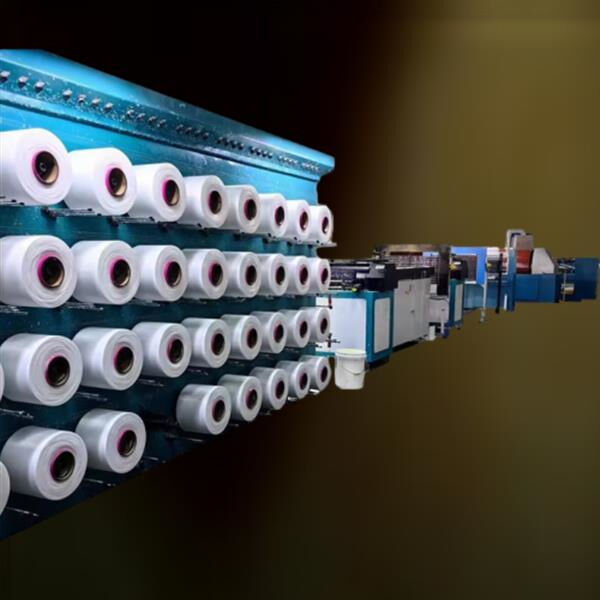

fourniture de fil et de machines depuis plus de 12 ans et disposons d'un département de recherche et développement de pointe. Nous mettons constamment à jour notre technologie. De plus, nous disposons d'un atelier de 30 000 m² pour la production de machines et d'un atelier de production de nylon/polyester de 20 000 m². Notre équipe est dédiée à vous fournir des machines de haute qualité. Chaque membre de notre équipe est extrêmement dévoué et responsable de sa tâche quotidienne. Nous espérons que notre expertise et notre technologie vous apporteront un meilleur travail.

l'entreprise a été fondée en 2013. Notre entreprise a vendu 300 produits au cours des 11 dernières années et nous sommes une entreprise leader sur le marché. Notre entreprise est une société spécialisée dans la conception, la fabrication et la vente de machines à déroulement divisé et de fils. L'équipe des ouvriers de l'usine possède des compétences et une expérience professionnelles.

L'équipe de filaments texturés a toujours été une équipe axée sur le client, et ils sont bien conscients que la satisfaction des exigences des clients est cruciale pour le succès de l'entreprise. Ils écoutent attentivement les retours de leurs clients et optimisent la production et les services pour satisfaire leurs besoins et attentes.

la machine à fil mère sectionnelle peut produire un bobineau avec une tension identique, à une vitesse de 550 m/min pour la filière mère en nylon. Elle a également créé la première machine capable de produire de la filière mère en polyester DTY. Nos produits sont faciles à installer, simples à configurer, faciles à utiliser et nécessitent peu de personnel.