Mencari bahan yang kuat namun bebas pemeliharaan? Nah, maka benang nilon spun dibuat untuk Anda! Ini adalah jenis benang yang umum dan dalam kegunaan sehari-hari kita melihat jenis ini. Artikel ini akan membahas mengapa profixM benang Nilon sangat luar biasa, polimer apa yang digunakan untuk membuatnya, di mana aplikasi benang semacam itu dan bagaimana peningkatannya selama bertahun-tahun karena perkembangan teknologi.

Namun, ada begitu banyak manfaat luar biasa dari jenis bahan ini: benang nylon. Pertama-tama, benang ini sangat kuat sehingga tidak mudah putus meskipun beban relatif kecil, artinya cocok untuk berbagai macam aplikasi. Kedua, salah satu hal menarik tentang nylon adalah bahwa karena tidak menyerap air, ia kering dengan cepat. Hal ini tentu saja menguntungkan untuk barang-barang yang mungkin basah atau perlu dicuci dengan frekuensi tinggi. Terakhir, nylon cukup tahan terhadap kerusakan lingkungan seperti kimia dan jamur, yang memperpanjang umurnya. Dan sangat mudah dirawat; Anda bisa mencucinya, menjemurnya, menyetrikanya, atau melakukan apapun yang Anda suka tanpa merusak serat secara permanen. Selain itu, benang nylon juga lebih murah di pasar dan tersedia di mana-mana.

Anda dapat mengenali benang nylon putar sebagai jenis serat multifaset yang terlihat dalam produk umum seperti pakaian, tas, busa bantal, dan karpet pile yang kita gunakan sehari-hari. Dalam pakaian, nylon sering digunakan dalam campuran dengan bahan lain (seperti katun atau poliester) untuk menambahkan beberapa kualitas unggul yang khas dari nylon. Nylon dapat ditemukan pada kaus kaki, pakaian renang, dan barang-barang pakaian lainnya yang memerlukan elastisitas dan keawetan. Nylon adalah pilihan yang bagus untuk tas dan sepatu karena sangat awet dan tahan air sehingga memastikan barang-barang Anda tetap aman dan kering. Salah satu tempat di mana nylon sering digunakan adalah untuk membuat kain penutup furnitur agar warnanya tetap tahan lama dan awet. profixM benang nylon adalah pilihan praktis untuk penggunaan di rumah dan bisnis karena sifat tahan lamanya yang resisten terhadap kerusakan serta noda pada karpet.

Terdapat beberapa langkah penting dalam proses pembuatan benang spun nylon. Benang spun nylon: Ini adalah produk yang terbuat dari serat nylon khusus, yang berasal dari sumber daya alam seperti batubara, air, dan udara. Langkah-langkah produksi meliputi - pencampuran, spinning, peregangan, penggulungan. Nylon, dasar dari benang: Pertama, nylon dicampur untuk membentuk bahan baku. Kemudian, nylon dipanaskan kembali dan diekstrusi melalui lubang-lubang sangat halus yang disebut spinneret sehingga membentuk serat-serat panjang. Filamen-filamen ini kemudian direntangkan untuk diperkuat, dan hasilnya meningkatkan kualitas benang. Setelah itu, benang digulung ke dalam spool atau cone yang menciptakan cara yang terorganisir untuk menyimpan dan menggunakannya sesuai kebutuhan.

Di berbagai bidang, benang nilon putar memiliki penggunaan yang lebih luas. Biasanya ditemukan di industri fesyen, di mana ia membuat produk seperti kaus kaki, baju renang, dan pakaian lainnya karena sangat kuat namun tetap lembut saat disentuh. Industri Otomotif — Benang nilon adalah bahan tekstil umum untuk membuat penutup kursi dan permadani mobil karena tahan lebih lama dan tidak mudah rusak oleh sinar matahari seperti bahan tekstil lainnya. Benang nilon sepenuhnya aman untuk tubuh dan tidak menimbulkan bahaya. Itulah sebabnya nilon telah digunakan dalam bidang medis untuk membuat jahitan bedah yang dapat dicuci dan alat-alat medis selama bertahun-tahun. Selain itu, profixM benang Nilon 100% juga digunakan dalam konstruksi untuk memperkuat beton, memberikan kekuatan tarik dan ketahanan yang lebih baik pada beton sehingga meningkatkan keselamatan dan keandalan bangunan dan struktur.

Perkembangan teknologi telah membuat benang nilon staple menjadi jenis produk yang lebih baik. Contoh yang baik dari ini adalah satu jenis nilon yang dicelup menggunakan teknik dalam proses pembuatannya. Artinya, warna menjadi terintegrasi dengan serat pada tingkat molekuler dan oleh karena itu sangat tahan luntur, hilang akibat pencucian, dll. Terakhir, ada pembuatan benang nilon dari berbagai produk limbah termasuk jaring ikan, karpet lama, dan material pasca-konsumsi lainnya untuk dapat daur ulang sumber nilon yang sudah ada. Berita baiknya adalah proses ini mengurangi penumpukan limbah di tempat pembuangan sampah dan memanfaatkan sumber daya tetapi tetap menjadi serat yang kuat dan tahan lama yang bersaing dengan produksi baru untuk banyak produk yang dapat digunakan.

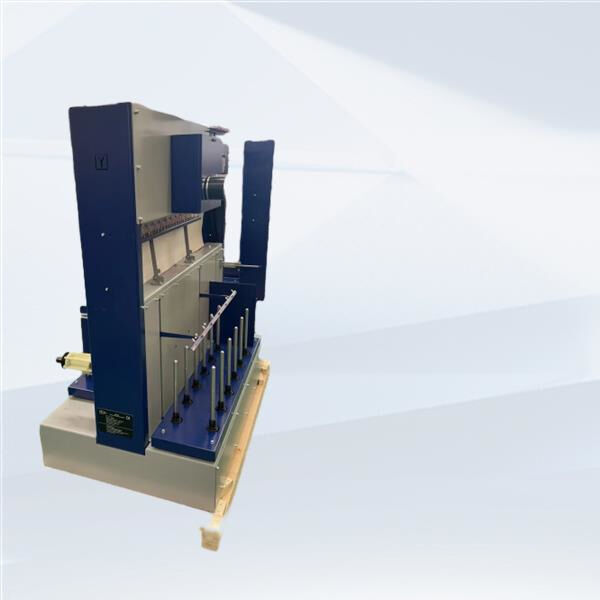

menyediakan benang dan mesin lebih dari 12 tahun dan memiliki departemen penelitian dan pengembangan berkualitas tinggi. terus memperbarui teknologi kami. Selain itu, memiliki bengkel produksi nylon/poliester seluas 20.000m2. Tim kami adalah penyedia mesin benang nylon dengan kualitas tertinggi. Setiap anggota staf bertanggung jawab atas pekerjaannya. Kami berharap bahwa keahlian dan teknologi dapat membantu memberikan pengalaman yang lebih baik.

produk mudah dipasang, benang nylon beroperasi.

tim manufaktur selalu berfokus pada pelanggan, mereka menyadari bahwa kepuasan permintaan pelanggan penting bagi pertumbuhan perusahaan. Mereka secara aktif mendengarkan umpan balik pelanggan tentang benang nylon untuk mengoptimalkan layanan produksi dan memenuhi kebutuhan serta harapan mereka.

perusahaan memproduksi benang spun nylon pada tahun 2013. Telah menjual 300 produk dalam 11 tahun terakhir, kami adalah pemain teratas di pasar. Bisnis kami adalah perusahaan niche yang merancang, memproduksi, dan menjual peralatan split-warping serta benang. Tim pekerja pabrik sangat terampil dan berpengalaman.