POY or Partly Oriented Yarn is in fact another name for polyester yarn. It is slightly elastic in producing in order to enable the user to easily fix it when using it. It thus lacks with it the strength that it has with other forms of yarn like the fully drawn yarn stretching which has been received much better. This profixM yarn split is a little more elastic than other equivalents but is less lustrous also and while blending properties of fabric it has more elasticity and travel distance.

This is an interesting process how POY produced. This time around it begins with small roundish of polyester that is liquefied. This melted plastic is cooled and then pulled to very thin threads of structures resembling strips. They are packed and joined to each other by a different special device called spinneret. The spinneret design also enables the creation of multiple strands of fibers in one setting which is economical in the sense that time and energy.

It is used in the development of multiple textile products. POY is typically converted to yarn by spinning or texturing the fiber for sale as profixM textured yarn; however it is a component of a carpet system in order to undergo heat treatments for elasticity and component type. Its characteristic drape type is ideal for most wear that needs the factor of flexibility like socks, leggings and wear that includes exercises. It welcomes this fabric to feel, fit and beau classy on the body.

Besides the apparel, the POY can also be processed into textured yarns. There are light and shade yarns related to texture yarns and these yarns look more attractive as compared to smooth yarns. They meet this by the use of a certain style of machine that arranges and interconnect the fibers differently in a kinked manner (AP4). Due to fiber character of worsted-wool yarns the development of textile with aesthetic appearance is possible.

This returns us to pros and cons of using POY, the truth is that at what I like about POY is that they are quite compliant and can easily be pulled. And this makes it the most appropriate texture to apply in developing clothing that is elastic in the human body. The last advantage of use of POY is that usually POY is cheaper offer than fully oriented yarns. By reducing feedback amount, the cost of the approach is also pleasant to both the manufacturer and the consumer.

However, they are also some disadvantage of using the POY that is stated below. However, POY fabrics may lose some of this advantage because they are partially O, or not as O as FOYs Fabrics produced from POY may degrade in strength or may be more likely to rip in future. Moreover, the research also reveals that POY also have different melting point than fully oriented yarn. It is not therefore ideal for packaging products that have to be baked or used in high heat operations; that is, high thermal inertia products.

This is helpful for the future of POY as new research is conducting more advanced techniques for increasing the stiffness and strength of the product. There is increasing investment that targets the creation of enhanced manufacturing method that would add more value to POY. Though profixM yarn texturising still has new uses that are being discovered by the innovators. For instance, they are eyeing one that could be used to develop the objects of intelligent textiles that can monitor body temperatures and heart rate, among others signs, as well as detect smaller chemical particles in the air.

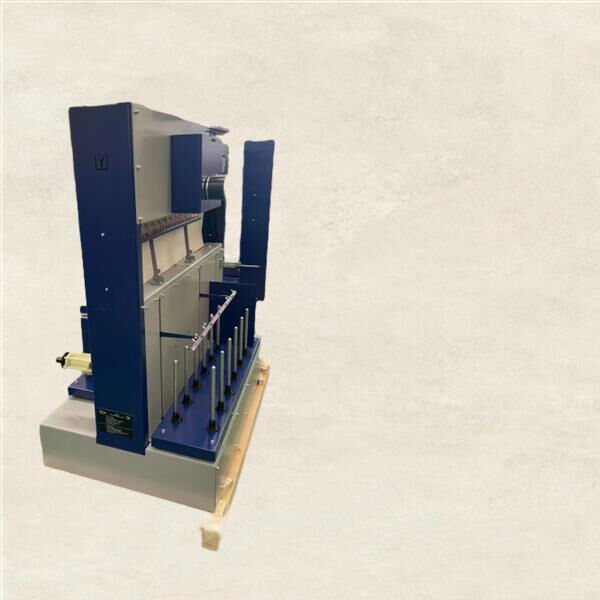

sectional mother yarn Partially oriented yarnwarping machine produce even tension beams with 550m/mins speed nylon mother yarn. also invented the first machine make polyester dty mother yarn.products are simple install, easy to set up, and easy to operate, have no demands on workers.

factory team has been customer- Partially oriented yarn, they are well aware that customer needs satisfaction are key to success of the company. They actively listen the voices of their customers, as well as optimize production service satisfy their requirements and expectations.

research and Partially oriented yarn team at our company is of best quality. We have provided yarn other equipment for over 12 years. We are constantly upgrading our technology. also have 30,000m2 machine production workshop and 20,000m2 nylon/polymer production workshop.Our team is committed providing you with supreme quality machines. Every member the team is extremely dedicated and accountable for all of their job. hope that our expertise and efforts will assist create more efficient work.

company was Partially oriented yarnin the year 2013. have sold 300 products over the last 11 years, we are the market top player. Our business a niche company that designs, manufactures sells split-warping equipment and yarn. team of factory workers is extremely skilled experienced.