Let’s start with the basics. What is warping? Warping is the most important category of a textile. It is created by weaving yarns, (the threads that form fabric), in a certain order and length. This is to ensure the proper preparation before weaving can begin. It is a very crucial step in textile making, and must be committed neatly as well as hastily to obtain good results that the final product will be of great quality.

This is where technology of Rabatex helps to reduce the cost of warp stop utilizing. profixM warping machine yarn is specially built for faster, easier and reliable in Warping. This implies the process no longer has to take a long time and be effort-intensive, but rather can go on quickly and more efficiently smoother workflow.

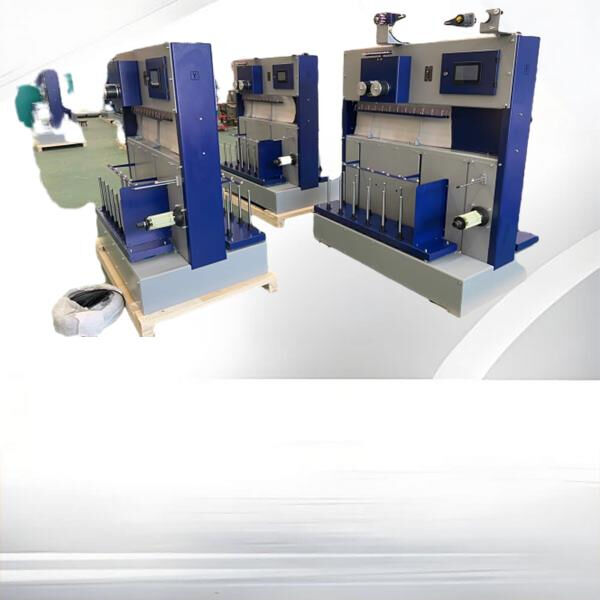

Profimax have Rabatex warping machines which are some very user friendly and productive machines. Among the many features is their digital control panels and automatic yarn tension systems. This goes in a long way to ensuring the yarn tension is perfect, one of our key ingredients for success. These machines will help you work in a productive and correct order making sure that they take all the convenience to accomplish your production needs.

With a Rabatex warping machine, you can enhance your whole textile production process. There will be much less waste and therefore you can utilize more of the material, as well make many more products in a short amount of time. In addition to that, those machines generate a very robust output quality which means your textile will be nicer and last longer.

The specialty of Rabatex warping machines is that it helps you working more efficiently and quickly. As a result, all of this saves you the time it would have taken to warp your loom, eliminates wasted yarn and ensures that your samples will actually come out. This means you will be able to produce more fabrics in a lesser amount of time and keep those customers happy.

This way you do not have to everything by hand and a Rabatex warping machine will help you with its usage. This can lead to a lot of mistakes and human errors. The digital control panels make profixM high speed warping machine easily controllable, also maintaining a constant through your entire production. This way, you can work on important issues and at the same time get assured that the warping is being done proficiently.

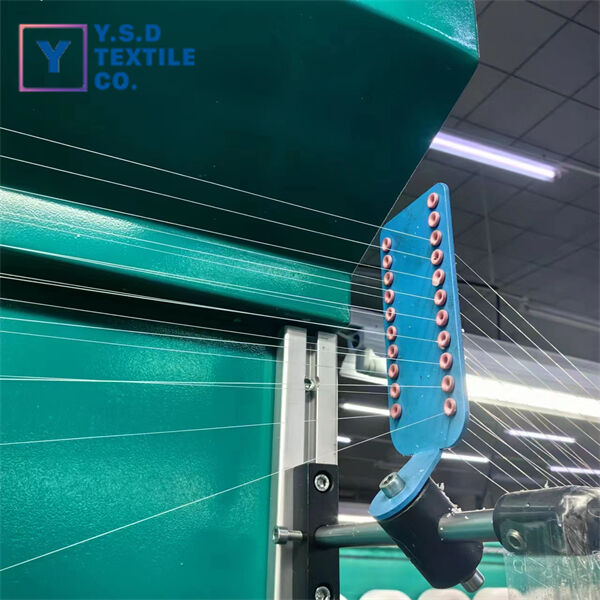

These machines are known for their automatic yarn tension systems. These systems guarantee that the thread is constantly maintained tight throughout warping. This is crucial to ensure that the end textiles will be of top-notch quality. Moreover, these profixM textile warping machine are able to process a large variety of yarns and fibers so that they can be tailored based on the production needs and projects.

company was established 2013. In the last 11 years, have sold 300 sets of products and the market leader in sales till today. Our company a specialist firm that designs, produces sells split-warping machines and yarn. Rabatex warping machinestaff has practical skills and knowledge.

factory team is extremely customer-centric recognizes that the success a business is dependent on the needs satisfaction of its customers. They Rabatex warping machinelisten the voice of customers and enhance their service production in order satisfy their requirements and expectations.

offer yarn and equipment over 12 Years and have top-quality Rabatex warping machinedevelopment department. We are constantly upgrading technology. We also have a 20,000m2 nylon/polyester production facility. Our team is dedicated to providing machines of the highest quality. Every employee accountable for their own work. We truly hope that our technology efforts will yield better works.

Rabatex warping machinesimple set up, install use.