Warping Machine is a Machine which wears the Yarn in form of Sheets on the Beam systematically. It is specifically designed to facilitate faster and more efficient carry out of the process of warping. It has a creel – the vessel where the yarn cones are placed, tension system so that the yarn is within the right compact and a beaming system which winds the yarn on the beam. In simple terms, the creel is the place where your yarn cones are kept, and the tension system keeps both the winding uniform unto your beam. The beaming system is used to tension or wind the yarn on the beam as it prepares to weaving process.

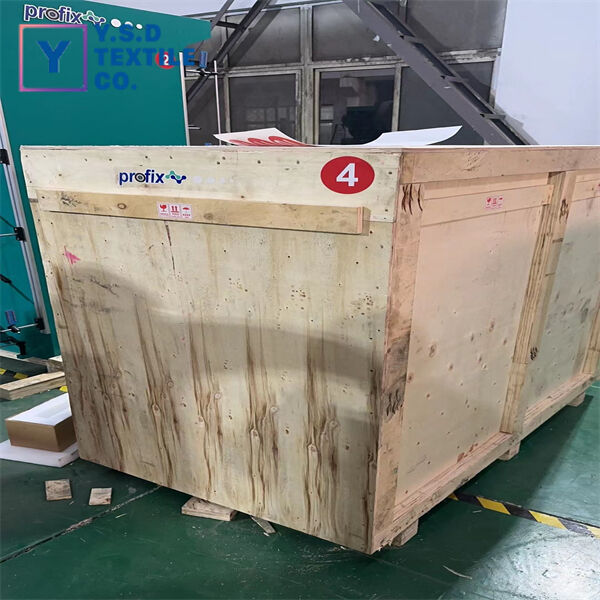

Perhaps the most notable of the changes is a new computerized warping machine. It continues from a series of machines with advanced computers and other packages to automatically set the precise tension, take-off and speed for each yarn cone to feed it evenly onto the beam. The profixM textile warping machine helps factories to produce better textiles with regional or defects problem for a better shoes quality end product.

The other big change is the use of lasers during the warping process in this series as opposed to in previous series. Where previously the tension of yarn could not even be measured let alone adjusted laser tools alone made it possible. As a result dead times are less and textiles produced is of better quality in terms of yard. And that means with the help of lasers they can rely for gentle and accurate treatment of their yarn that is crucial in order to manufacture luxurious fabrics

For this reason, it is of utmost importance to choose right warping machine parking system and take proper care of it. profixM textile warping machine that helping a machine to work properly and clean easily. Therefore, the created textiles will be of good quality, and contain what they expect to include in the fabrics they are to produce. This means that manufactories, who will devote necessary amount of time towards correct warping techniques, can create products that customers will appreciate and will last for years.

Alternatively, you use a stop frame system to help in increasing warping. Apart from that it was also able to turn off the machine automatically in the event of a snag and this helps prevent further distortion of yarns. This conserves costs, accelerates the rate of production and leads to production of a better quality textile. The early warning system enables the factories detect problematic areas so that they can handle them and reduce waste while offering the best to the public.

Lists of the most development exciting areas are: smart technology implementation. For the purpose of the analysis and optimization of the warping process, and with the help of the application of artificial intelligence, there has been applied a new intelligent type of Machines! Consequently, it is easy to achieve shorter production cycle time, reduction in wastes and production of quality textile. Smart technology provides an opportunity for the manufacturers to sustain a competitive ground in the market that keeps on evolving.

In addition there is also enhanced use of robots in textile industry. Fortunately, factories are manufacturing semi-automated robotic warping machines for human operators whose duties involve repetitive functions such as profixM warper textile utilizes to increase productivity and lower the risk of work-related injuries. That said, we will improve on the expected results by integrating the human qualities with the robots’ accuracy.

company was founded in 2013. have sold 300 products in last 11 years and are still the market leader. Our company a professional enterprise engaged in design production, Warping machine in textile, and sale of split warping machines as well as yarn. manufacturing team brimming with knowledge and expertise.

factory team is extremely customer-centric recognizes that the success a business is dependent on the needs satisfaction of its customers. They Warping machine in textilelisten the voice of customers and enhance their service production in order satisfy their requirements and expectations.

supply yarn and machine more than 12 years and are a top research development department. continue new Warping machine in textileupgrade. also have 30,000m2 of machine production workshop 20,000m2 of nylon/polymer production workshop.Our team is dedicated providing you with the highest quality machines. Every member our team is responsible for the work they do. We sincerely hope that our technology and efforts can help you achieve greater quality of work.

Warping machine in textilesimple set up, install use.