প্রবর্তন, প্রোফিক্সএম-এর অতি দ্রুত নাইলন পলিয়েস্টার মাদার সুতা বিভাজন মেশিন! এই শীর্ষ মানের সরঞ্জাম হল নাইলন এবং পলিয়েস্টার তন্তু দিয়ে কাজ করা উৎপাদন কারখানার জন্য অপরিহার্য যন্ত্র। এর শক্তিশালী কার্যকারিতা এবং নবায়নযোগ্য বৈশিষ্ট্যগুলির সাথে, প্রোফিক্সএম-এর মাদার সুতা বিভাজন মেশিন হল সর্বোচ্চ উৎপাদনশীলতা এবং দক্ষতা অর্জনের জন্য পেশাদারদের জন্য সেরা পছন্দ।

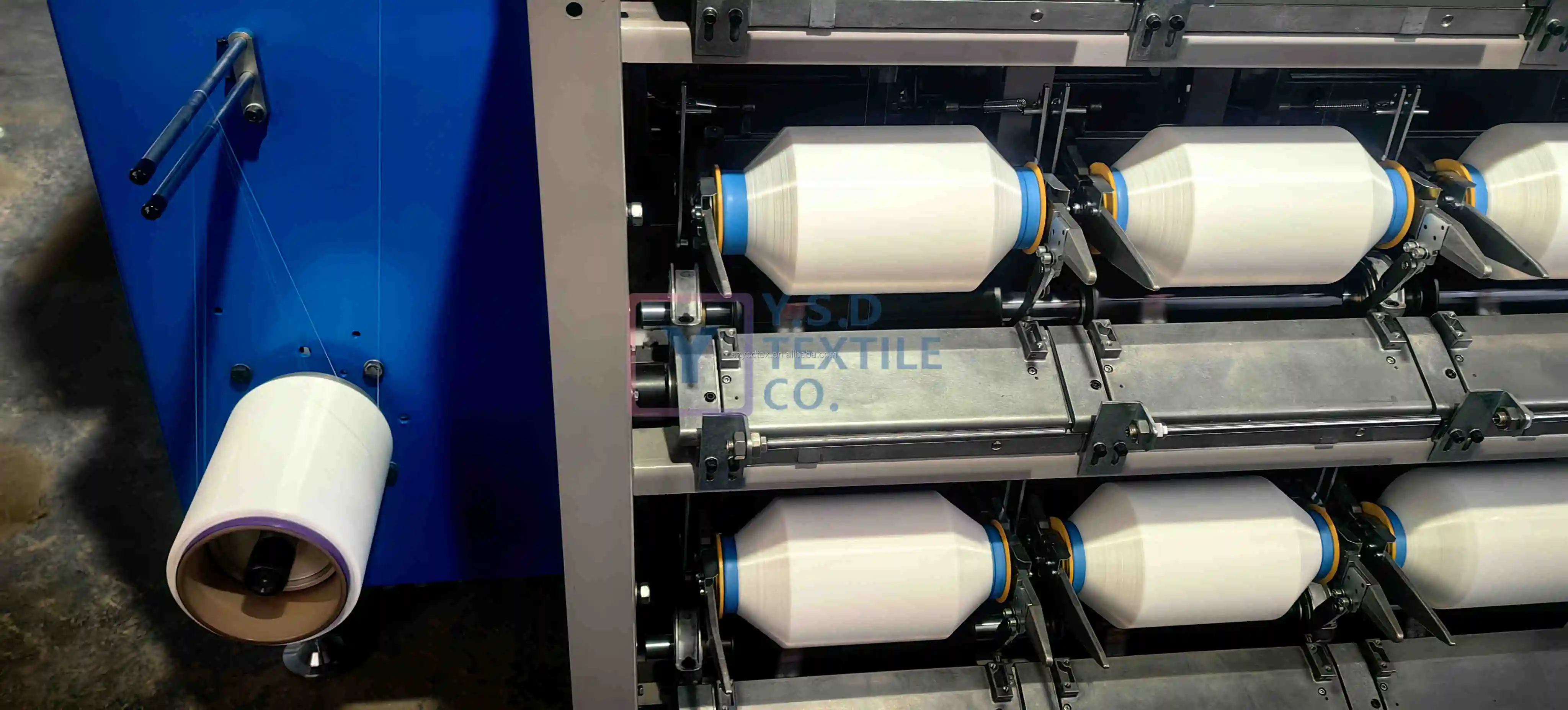

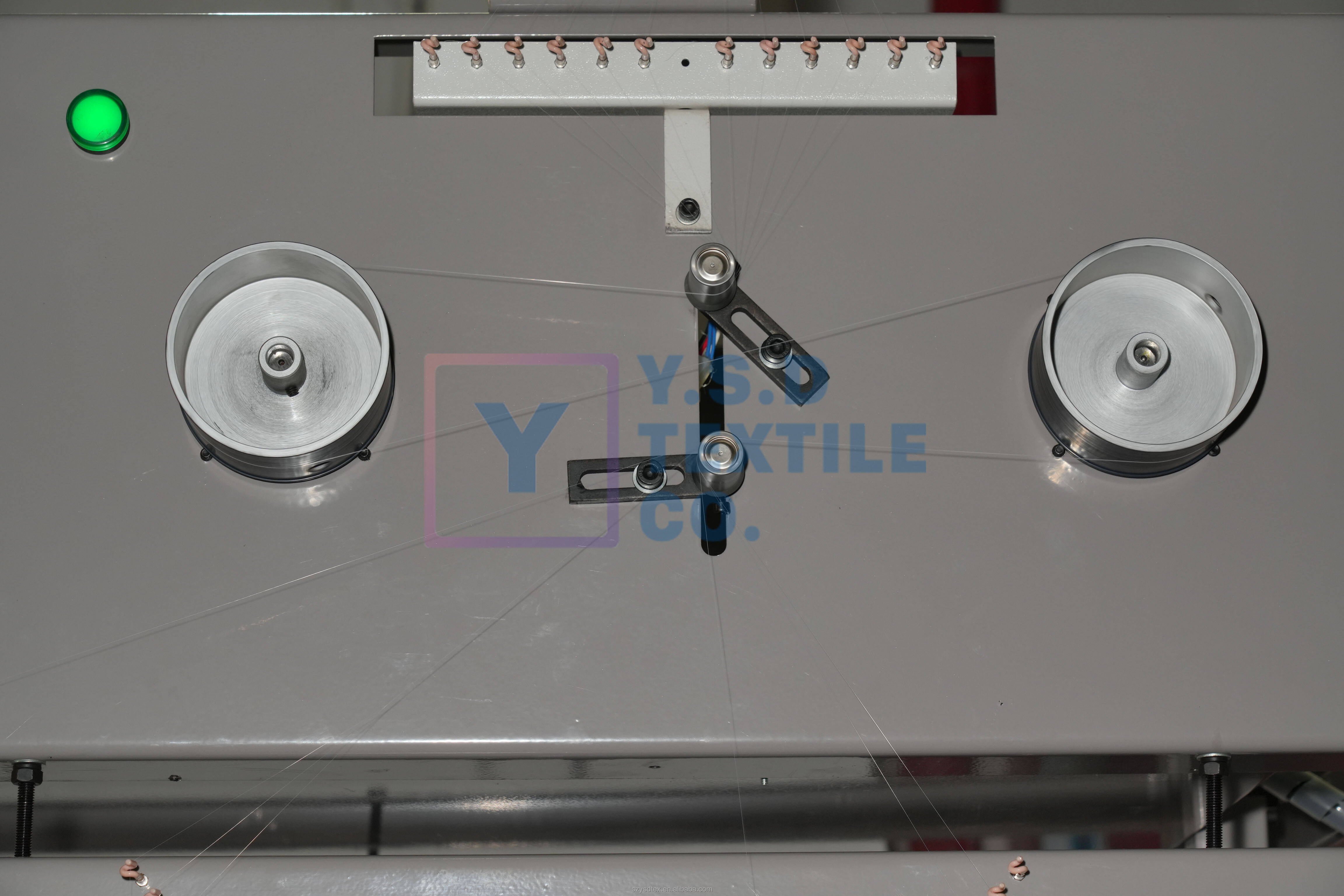

উচ্চ-মানের উপকরণ দিয়ে তৈরি এবং নিখুঁত প্রকৌশলের সাথে ডিজাইন করা, প্রোফিক্সএম-এর মাদার সুতা বিভাজন মেশিনটি ভারী ব্যবহারের পক্ষে টেকসই এবং প্রতিবার স্থিতিশীল ফলাফল দেয়। এই মেশিনটিতে রোলিং পেপারের বৈশিষ্ট্য রয়েছে, যা মাদার সুতাকে সমান মোটা ও আকারের একাধিক স্ট্র্যান্ডে বিভক্ত করতে সক্ষম করে।

এর উন্নত কাটিং প্রযুক্তির সাহায্যে, প্রোফিক্সএম-এর মাদার সুতা বিভাজন মেশিনটি অত্যন্ত দ্রুত এবং দক্ষ, যা একবারে সর্বাধিক ছয়টি মাদার সুতাকে বিভক্ত করতে দেয়। এর ফলে আপনি কম সময়ে বেশি পরিমাণে উপকরণ উৎপাদন করতে পারবেন, আপনার উৎপাদন ক্ষমতা বাড়াতে পারবেন এবং আপনার মুনাফা বৃদ্ধি করতে পারবেন।

প্রোফিক্সএম'-এর মাদার যার্ন স্প্লিটিং মেশিনটি ব্যবহারকারীদের বান্ধব এবং পরিচালনার জন্য সহজবোধ্য যা এমনকি নব্য ব্যবহারকারীদের কাছেও সঠিকভাবে পরিচালনার সুযোগ করে দেয়। মেশিনটি নিরাপত্তার দিকটি মাথায় রেখে ডিজাইন করা হয়েছে, যাতে অপারেটরদের সর্বদা নিরাপদ রাখা যায় এমন উপযুক্ত নিরাপত্তা ব্যবস্থা এবং রক্ষামূলক বৈশিষ্ট্য দিয়ে সজ্জিত।

নাইলন এবং পলিস্টার তন্তু দিয়ে কাজ করা যে কোনও উত্পাদন কারখানার জন্য প্রোফিক্সএম'-এর মাদার যার্ন স্প্লিটিং মেশিনটি একটি অপরিহার্য যন্ত্র। আপনি যেখানে কর্ড, দড়ি, কাপড় বা যে কোনও ধরনের উপাদান উত্পাদন করছেন না কেন, এই মেশিনটি আপনাকে সহজে এবং দক্ষতার সাথে আপনার উত্পাদন লক্ষ্য অর্জনে সাহায্য করবে।

প্রোফিক্সএম-এর হাই-স্পিড নাইলন পলিস্টার মাদার ইয়ার্ন স্প্লিটিং মেশিন হল উত্পাদন কারখানার জন্য আদর্শ সরঞ্জাম যারা তাদের উৎপাদনশীলতা এবং দক্ষতা সর্বোচ্চ করতে চায়। এর উন্নত বৈশিষ্ট্য, স্মার্ট প্রযুক্তি এবং উচ্চ মানের নির্মাণের সাহায্যে, প্রোফিক্সএম-এর মাদার ইয়ার্ন স্প্লিটিং মেশিন আপনার আশা ছাড়িয়ে যাবে এবং এমন ফলাফল দেবে যা আপনার গ্রাহকদের মুগ্ধ করবে। আজই অর্ডার করুন এবং এই অসাধারণ মেশিনের মাধ্যমে আপনার ব্যবসায়ের পার্থক্য অনুভব করুন

আইটেম |

মান |

পণ্য |

মেশিন |

ম্যাটেরিয়াল ক্ষমতা |

নাইলন এবং পলিয়েস্টার মনো সুতা |

ওজন (কেজি) |

600 |

মেশিনের প্রকার |

মাদর যার্ন স্প্লিটিং মেশিন |

ভিডিও আউটগোয়িং-পরীক্ষা |

প্রদান করেছেন |

যন্ত্রপাতি পরীক্ষার প্রতিবেদন |

প্রদান করেছেন |

মূল উপাদান |

ইঞ্জিন |

উৎপত্তিস্থল |

চীন |

|

জিয়াংসু |

ওয়ারেন্টি |

1 বছর |

নাম |

মাদর যার্ন স্প্লিটিং মেশিন |

ওয়াইন্ডিং কয়েল কঙ্কাল |

95-130x230মিমি |

বিভাজন টান |

0.6g/d- 1.0g/d |

মোড়ানো |

120*2300মিমি |

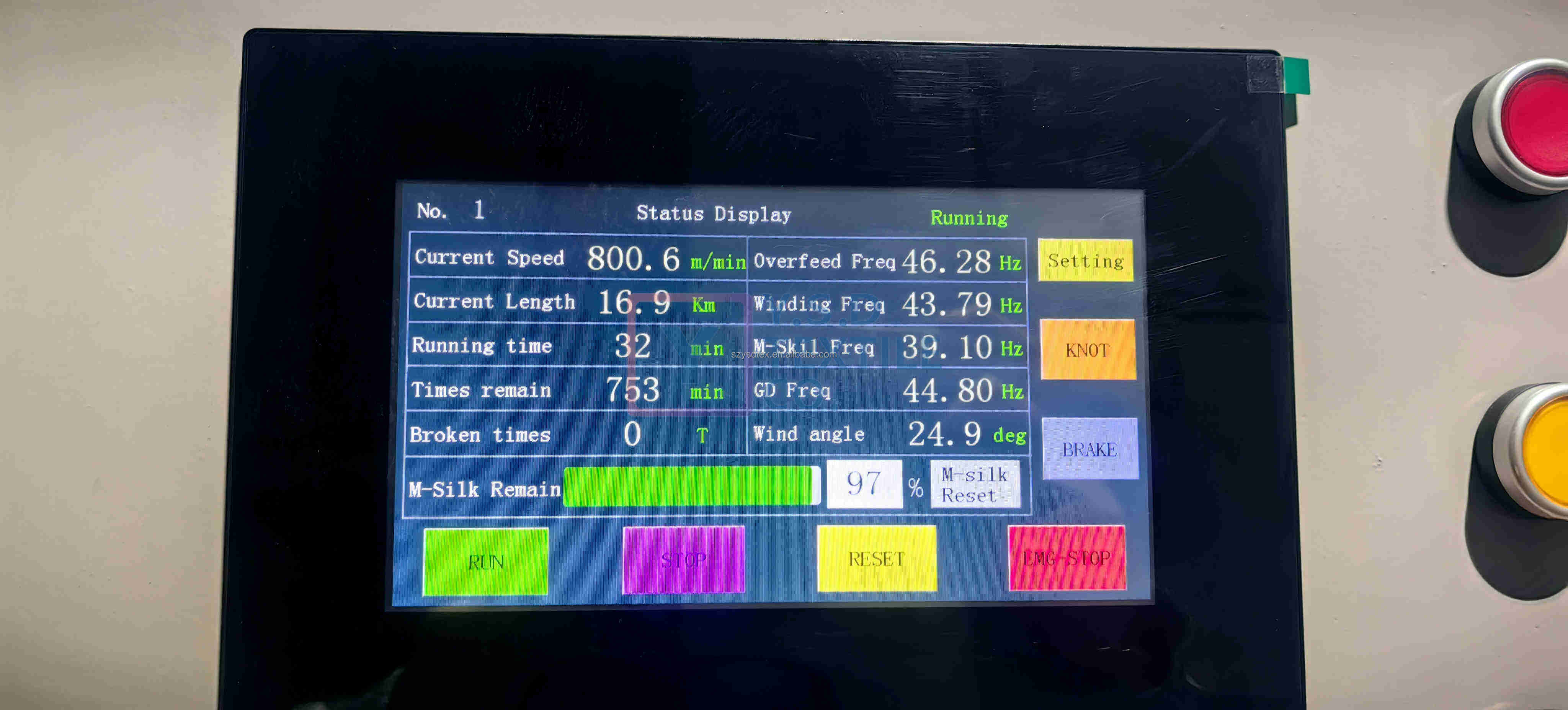

বিভাজন গতি |

200D/10F 800/min পর্যন্ত পৌঁছাতে পারে |

আকৃতি দেওয়ার যন্ত্র |

100মিমি-460মিমি |

স্পিন্ডল মোটর |

১কেওয়া |

ডেটা মোটর |

০.২৪কেউ |

ফর্মিং মোটর |

০.০২কেউ |

স্পিটিং মোটর |

০.০২কেউ |

মাদার সূতা বিভক্তকরণ মেশিন কাগজের ববিনে রোলিং

1. স্থিত টান শুরু থেকে শেষ পর্যন্ত প্রতিটি বিভক্ত ববিনে

2. ব্যবহার স্বাভাবিক ডিটিওয়াই কাগজের ববিন , কম উৎপাদন খরচ এবং সহজলভ্য

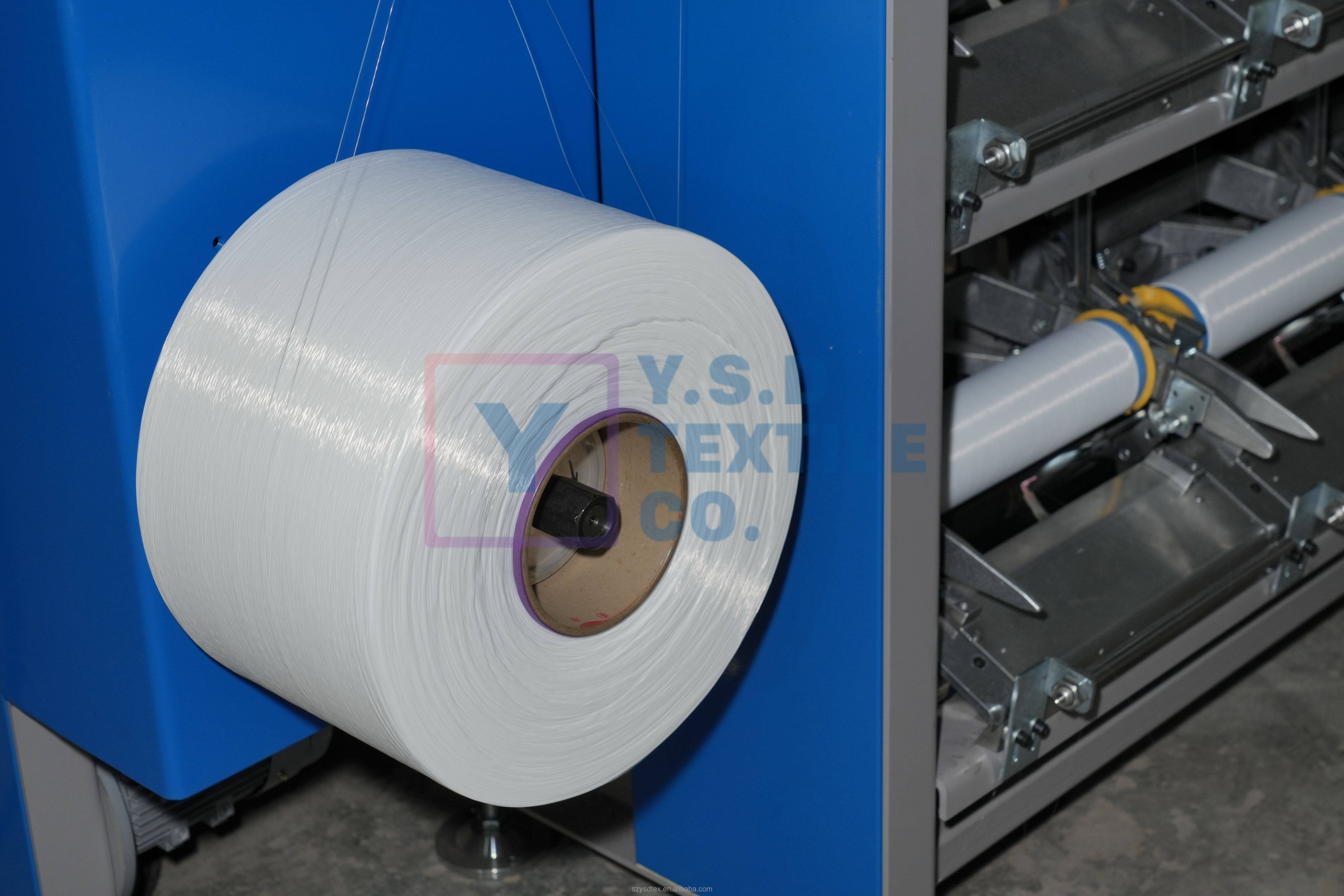

3. মাতৃ সুতা আকারের ওজনের কোনো সীমা নেই, 12কেজি -- 24কেজি চালানো যেতে পারে

4. চলমান গতি 800-900 মিটার/মিনিট

5. ঘর্ষণ ড্রাম নিয়ন্ত্রণ প্রতিটি স্পিন্ডেল, প্রতিটি বিভক্ত ববিনের একই আকার দরকার নেই, আপনার প্রয়োজন অনুযায়ী ববিন বিভাজনের সময় প্রতিটি ববিনের আকার স্থির করুন

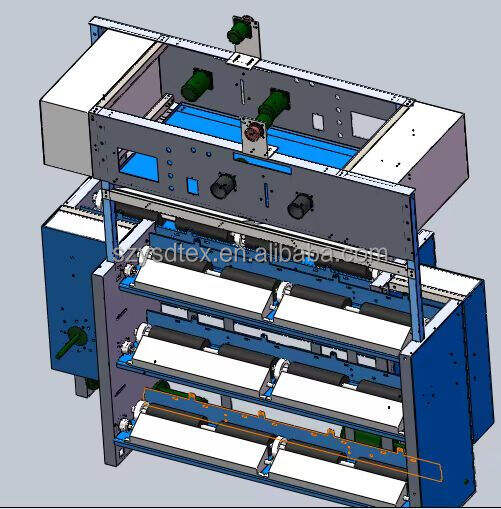

স্পিন্ডেল |

উচ্চতা |

দৈর্ঘ্য |

প্রস্থ |

24 |

1900mm |

২০০০ মিমি |

1000মিমি |

1. স্পিন্ডেল

এক পাশে ১২টি স্পিন্ডেল, দুই পাশে মোট ২৪টি স্পিন্ডেল (পৃথক নিয়ন্ত্রণ)

২. কাগজের ববিনের আকার

দৈর্ঘ্য ২৯০ মিমি, বহিঃস্থ আকার ৭৮ মিমি, অন্তঃস্থ আকার ৬৭ মিমি এবং ৫৬ মিমি,

৩. স্থিতিশীল টেনশন

ঘর্ষণ ড্রাম প্রতিটি ববিনের টেনশন একই রাখে

৪. রপ্তানি প্যাকেজ

১*২০জিপি-এ ৫টি সেট ১*৪০এইচকিউ-এ ১১টি সেট

৫. মাদার সুতা বিভক্ত করা

নাইলন এবং পলিএস্টার মোনো ধাগা 10D-70D, 12F এর মধ্যে

৬. সহজ নিয়ন্ত্রণ ব্যবস্থা

ডেল্টা মোটর্স, ইংরেজি নিয়ন্ত্রণ ব্যবস্থা

সুজ়ু ওয়াইএসডি টেক্সটাইল কোং লিমিটেড ইয়াংসিক ডেল্টা নদীর পাড়ে পিংওয়ান টাউনে অবস্থিত, ২০০০০ বর্গমিটার জুড়ে রয়েছে, প্রধানত শীর্ষ মানের হাই-স্পীড মাদার সুতা বিভাগীয় স্প্লিট ওয়ার্পিং মেশিন, মাদার সুতা বিভাজন মেশিন, নারীদের সমস্ত ধরনের কাপড়, উজিয়াং টেলং কেমিক্যাল ফাইবার কোং লিমিটেড জেনজে টাউনে অবস্থিত, ২০০০০ বর্গমিটার জুড়ে রয়েছে, নাইলন/পলিস্টার মোনোফিলামেন্ট সুতা, মাদার সুতা, অর্গানজা (টেক্সচার্ড) সুতা, ফেদার সুতা প্রতি বছর ৮০০০ টন, আমাদের স্পিনিং ভবনের তৃতীয় পর্যায় নির্মাণ শুরু হয়েছে, সম্পন্ন হলে বার্ষিক উৎপাদন ২০০০০ টনের বেশি হতে পারে। আমরা গ্রাহকদের দৃষ্টিভঙ্গির ভিত্তিতে আপনাকে সমস্যা সমাধানে সাহায্য করি, একসাথে বাড়ুন, পারস্পরিক সুবিধা ও উইন-উইন

1. উৎপাদনের সময় কেমন প্রতিটি মেশিনের উৎপাদন সময় 40-50 দিন, প্রতিটি গ্রুপে 50 সেট

2. অর্থ প্রদানের শর্ত কেমন

টি/টি 3/7 ডেলিভারির আগে, এলসি অ্যাট সাইট

3. উৎপাদন পরিমাণ কেমন

প্রতি মেশিনে (দুই পাশে) প্রতি 24 ঘন্টায় 60 কেজি নাইলন 240/12 মাদার সুতা চালানো হয়

4. মেশিনের গতি কেমন

সাধারণত 800-1000 মিটার/মিনিট গতিতে চালানো হয়

5. বৈদ্যুতিক ম্যাচের অবস্থা কেমন

ডেল্টা মোটর ব্যবহার করুন, চলমান শক্তি প্রায় 2 কিলোওয়াট, শুরু করার শক্তি 1.5 কিলোওয়াট

আমাদের সাথে যোগাযোগ করুন:

হোয়াটসঅ্যাপ/ ওয়েচ্যাট/ ফোন করে রোজির সাথে যোগাযোগ করুন: +86 152 6197 6205

EN

EN

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

RO

RO

RU

RU

ES

ES

ID

ID

UK

UK

VI

VI

TH

TH

TR

TR

BN

BN

NE

NE