Did You Ever See the Giant Machines of a Textile Factory? Granted, they look like complex contraptions with all their intricate parts, but they have a singular function: to move lots and lots of air. Their primary role is converting fibers into fabrics. Today we are going find out more about an engine — how does this amazing machine work and what it does. Textile mill machinery by profixM are in existence since a long period. The 1st opened textile mill was in late 1700s England. The warping machine in textile were originally powered by water, which meant they required flowing streams or rivers to function. It could only do very basic patterns in the fabric back then. However, with time people found new ways to enhance these machines. All of this led them to improve and evolve into something beautiful and intricate. This switch finally allowed fabrics to be manufactured at a much greater pace.

Even more interesting is the fact that fabric by profixM used to be made by hand. Artisans were capable of making decorated cloths in themselves. The process was very unique, but also extremely slow. And in order to provide all these textiles, the clear answer was that it could simply not be done out of people's homes anymore. This is why the role of texturing in textile machinery is so vital. All I mean in the end is that they will be creating fabrics and doing so much faster than any person. Nonetheless with these machines we have to be sure everything is functioning properly also, so we need qualified workers. Think of the orchestra and these workers are the conductors making sure everything sounds just right.

Machines in a textile mill by profixM demonstrate how new tech can disrupt the way products are made. Textile machines have come a long way from the first textile factory machine were powered by water to the modern, high-tech textile machines of today. While the machines themselves have evolved well beyond punch cards and microfilm, we still rely on skilled workers to keep them running. These are essential personnel who understand how to problem solve, fix and get the machines back up and running. So that the machines would do its best, human expertise was indispensable.

They may not seem fancy at first glance; but in reality, textile mill machines are the most powerful. Textile machine factory can start with a material such as cotton or wool and transform it into gorgeous, soft fabrics that we can put on whenever we want. Well, if you think about how these robots function and the impact they subconsciously have in our daily activities — it's super cool.

Next time you are getting dressed wearing a shirt, using a towel or wrapping yourself in a blanket – spend one moment being grateful for the effort that went towards producing machine. But think of those wonderful old textile machine supplier, which science made into efficient workers that make so much of the world to be better running clothes and furniture.

factory team extremely customer-centric and knows that success of business is dependent on needs and satisfaction of its clients. Customers are Textile mill machineslistened as well as production service are optimized meet customer expectations needs.

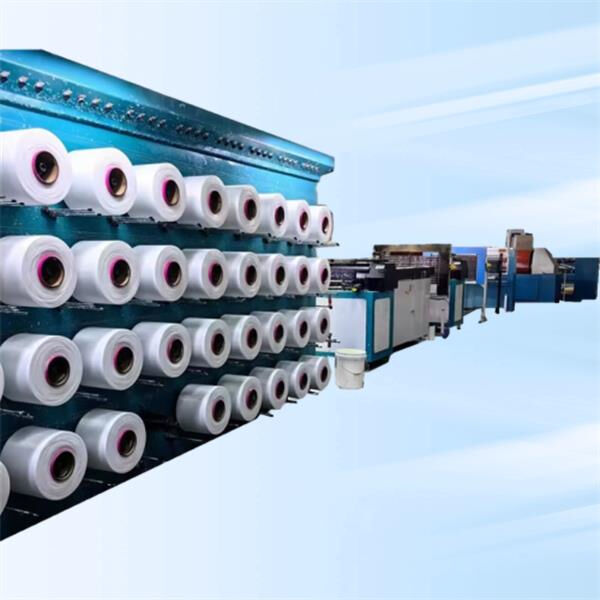

company was established 2013. In the last 11 years, have sold 300 sets of products and the market leader in sales till today. Our company a specialist firm that designs, produces sells split-warping machines and yarn. Textile mill machinesstaff has practical skills and knowledge.

have been providing yarn machines for more than 12 years. have top-quality research and development department. We constantly upgrade our Textile mill machines. Also, have a 20,000m2 nylon/polyester manufacturing workshop. staff is committed to supplying machines of the best quality. Every member the team is extremely dedicated and accountable for all of their job. We are confident that efforts and technology will result in more efficient productive work.

products simple to set up, Textile mill machinesuse.