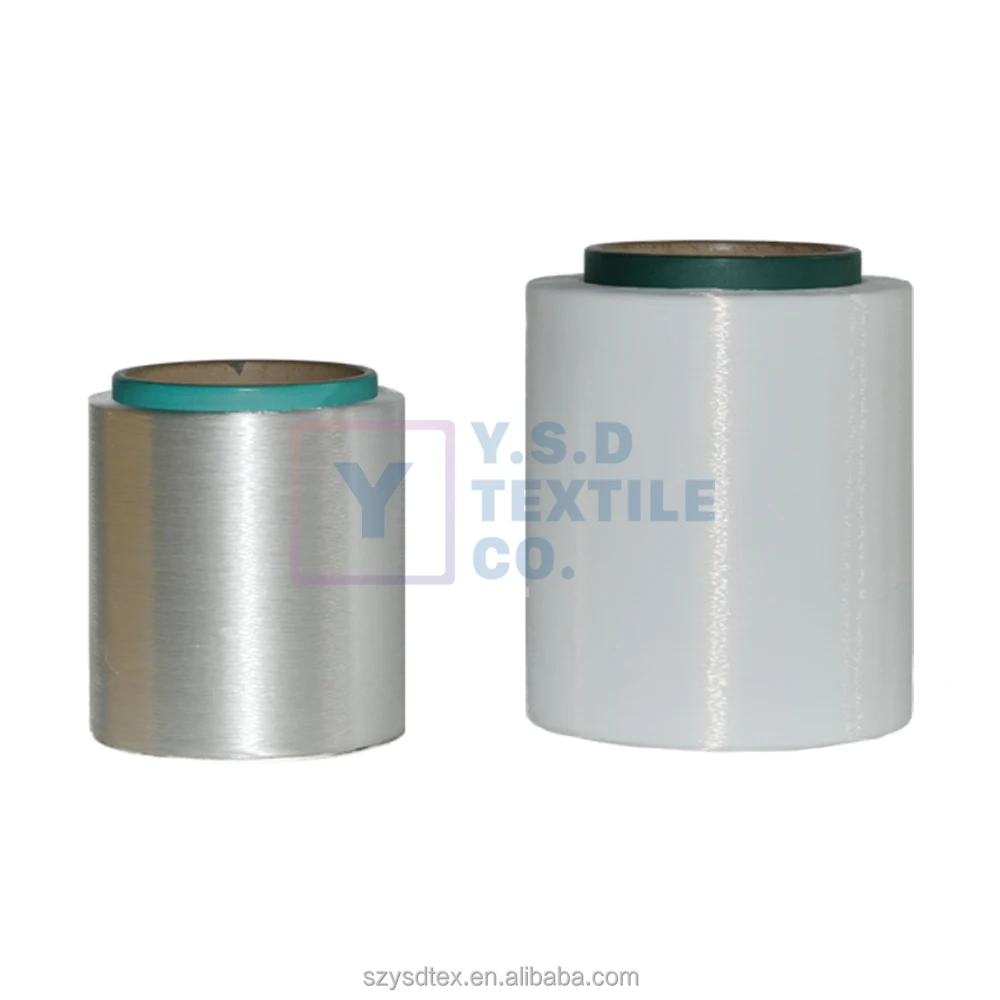

100% Nylon 240d/12f High Tenacity Mother Yarn SD Fiber Yarn for Knitting Fdy Nylon Mother Yarn

- Overview

- Inquiry

- Related Products

Product Description

Specification

item |

value |

Place of Origin |

China |

Jiangsu |

|

Use |

Knitting, Sewing, Weaving, Hand Knitting |

Material |

100% Nylon |

Yarn Type |

Fdy |

Pattern |

Raw |

Style |

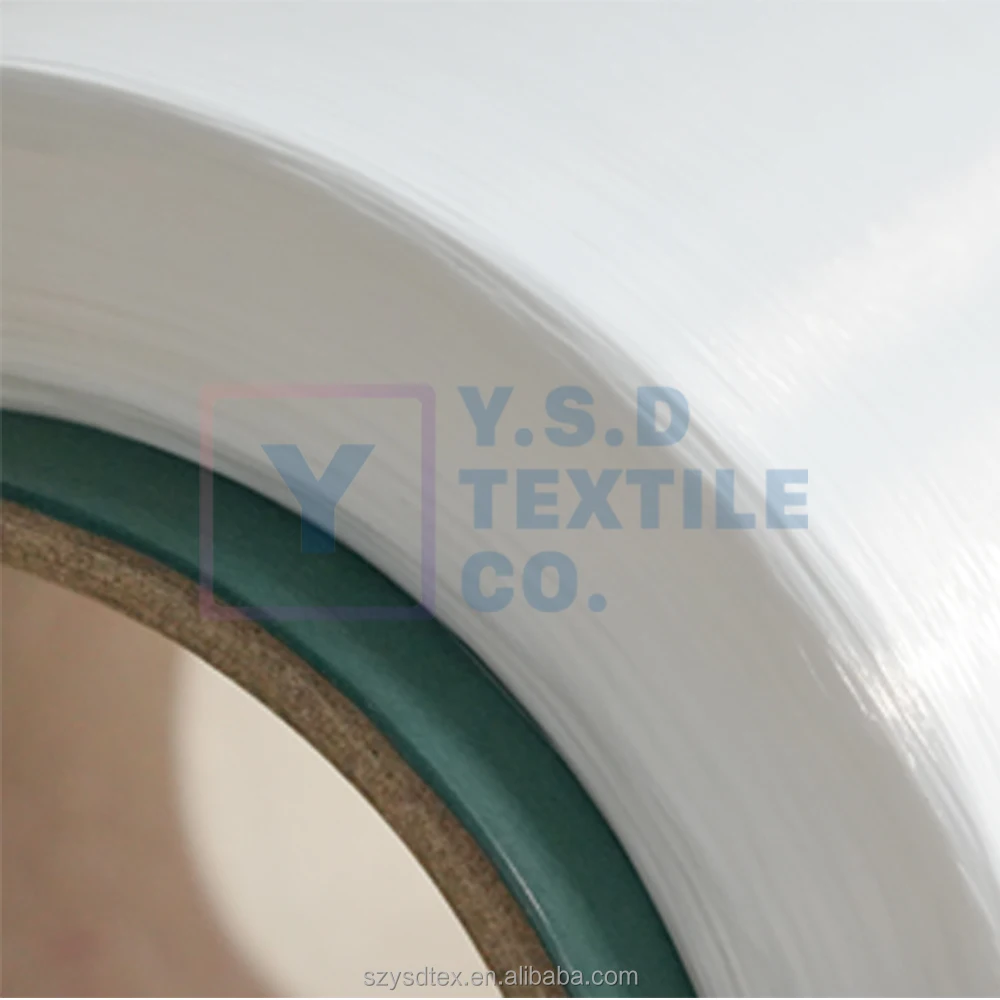

Filament yarn |

Feature |

Anti-pilling, Moisture-Absorbent, High Tenacity, Anti-Bacteria |

Twist |

non |

Evenness |

1% |

Yarn Count |

240D/12F |

Strength |

>4.0cN/dtex |

Model Number |

240D/12F |

Product name |

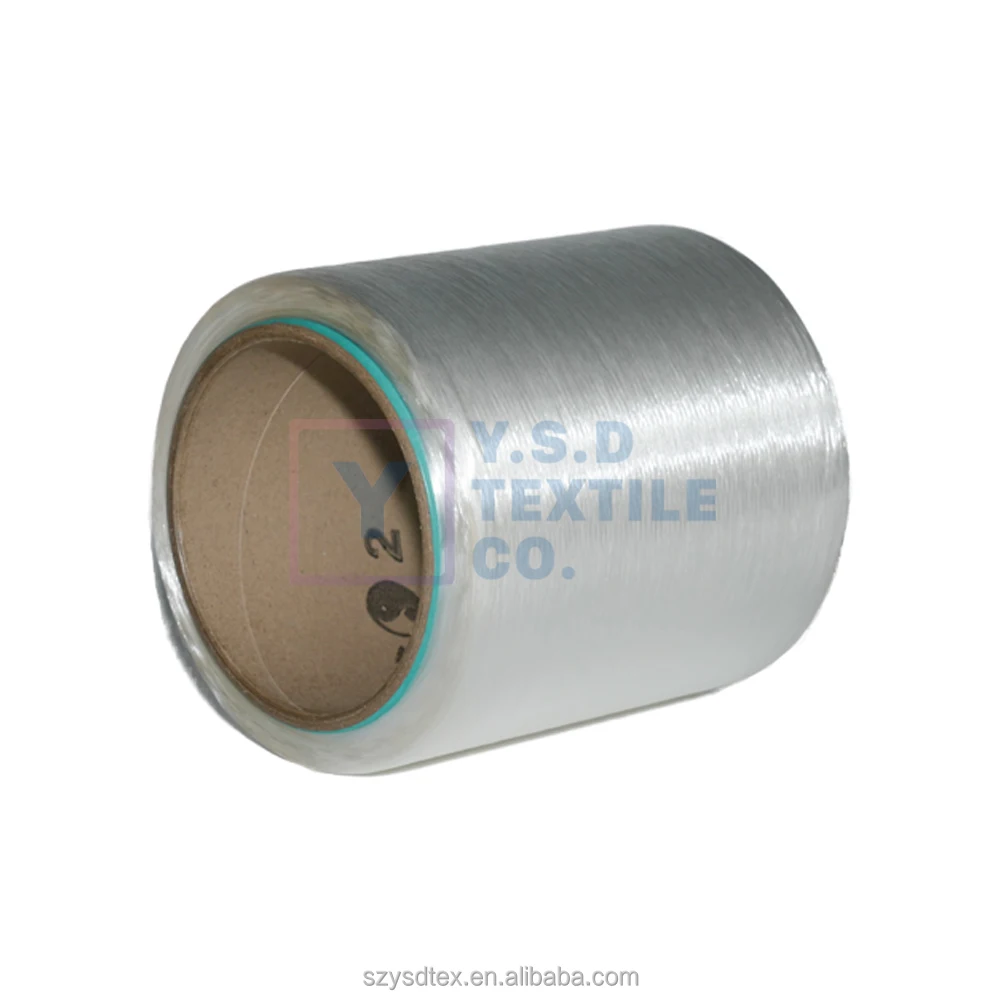

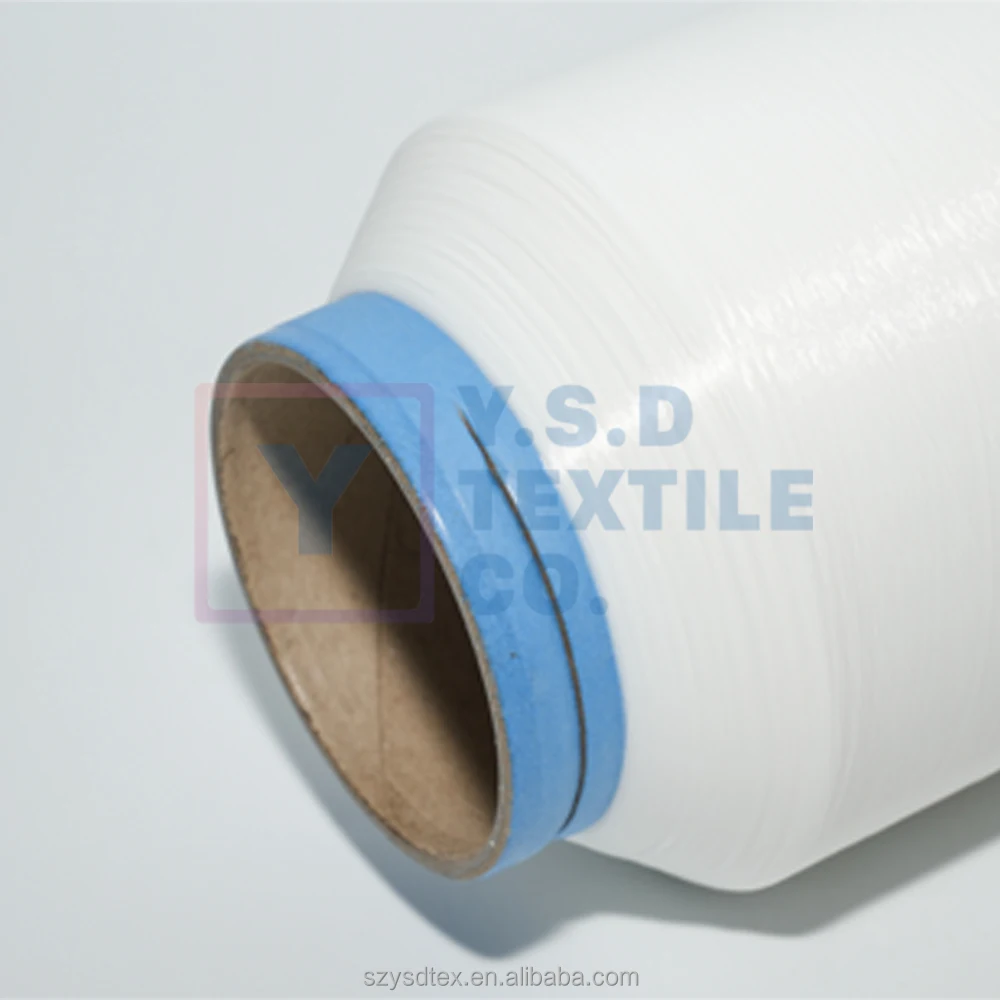

PA6 Nylon Polyamide 240D12F FDY semi dull SD mother yarn |

Usage |

Knitting Weaving Sewing |

Colors |

semi dull |

Denier |

240D/12F |

Packing |

Paper Robbin |

Luster |

semi dull |

Yarn style |

FDY |

Quality |

Grade AA |

Payment Term |

TT LC |

Stretch |

>4.0cN/dtex |

Raw silk is one of the main objects processed by the warping machine, and the design and function of the warping machine are closely focused on the characteristics of the raw silk to ensure the smooth progress of the warping process and the high-quality warping effect

Raw materials such as polyester, nylon, etc. are the main materials processed by the warping machine. During the warp knitting process, a single strand mother wire is composed of several single filaments. The warp knitting machine can greatly save customers' raw material costs, while also saving production space and improving productivity

About Us

About Us

Suzhou YSD Textile Co., Ltd. is located in Pingwang Town, Yangtze River Delta, covers an area of 20000 square meters, mainly produces top grade high-speed mother yarn sectional split warping machine, mother yarn splitting machine, all kinds of women's fabrics, subordinate Wujiang Telong Chemical Fiber Co., Ltd. is located in Zhenze Town, covers an area of 20000 square meters, production of nylon/ polyester monofilament yarn, mother yarn, organza (textured) yarn, feather yarn 8000 tons each year, our third phases of spinning building has started construction, after the completion of the annual output can be above 20000 tons. We are based on the perspective of customers, to help you solve problems, grow together, mutual benefit and win-win.

Our loyal customers have already beenenjoying the prohts which ware created byusing Yunshunda high technology machine.We believe that our machine will be the rightchoice of your warping production.

Certifications

Through the certification we allow customers to our products with more confidencebut the most important thing is the quality of our products

Exhibition

FAQ

Q:Are you manufacturer?

A:Yes, We are manufacturer.

Q:How to place machines order?

A:Please send us your purchase order by email, whatsapp or wechat. We need to know the following information for your order:

(1)Your products width and thickness(webbing, tapes, lace width and thickness)

(2)Price Item, Destination Port, Delivery time required

(3)Shipping information: Company Name , Address, Phone Number , Destination Seaport/Airport

Q:What are the payment terms?

A:For orders, we can accept T/T, L/C at sight

Q:How many years of producing these machine?

---We produced these machine for more than 15 years.

Q:How to place machines order?

A:Please send us your purchase order by email, whatsapp or wechat. We need to know the following information for your order:

(1)Your products width and thickness(webbing, tapes, lace width and thickness)

(2)Price Item, Destination Port, Delivery time required

(3)Shipping information: Company Name , Address, Phone Number , Destination Seaport/Airport

Q:What are the payment terms?

A:For orders, we can accept T/T, L/C at sight

Q:How many years of producing these machine?

---We produced these machine for more than 15 years.

EN

EN

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

RO

RO

RU

RU

ES

ES

ID

ID

UK

UK

VI

VI

TH

TH

TR

TR

BN

BN

NE

NE