High-Speed Mother Yarn Warping Machine with Sectional Splitting Independent Research Fastest Speed High Efficiency New Condition

- Overview

- Inquiry

- Related Products

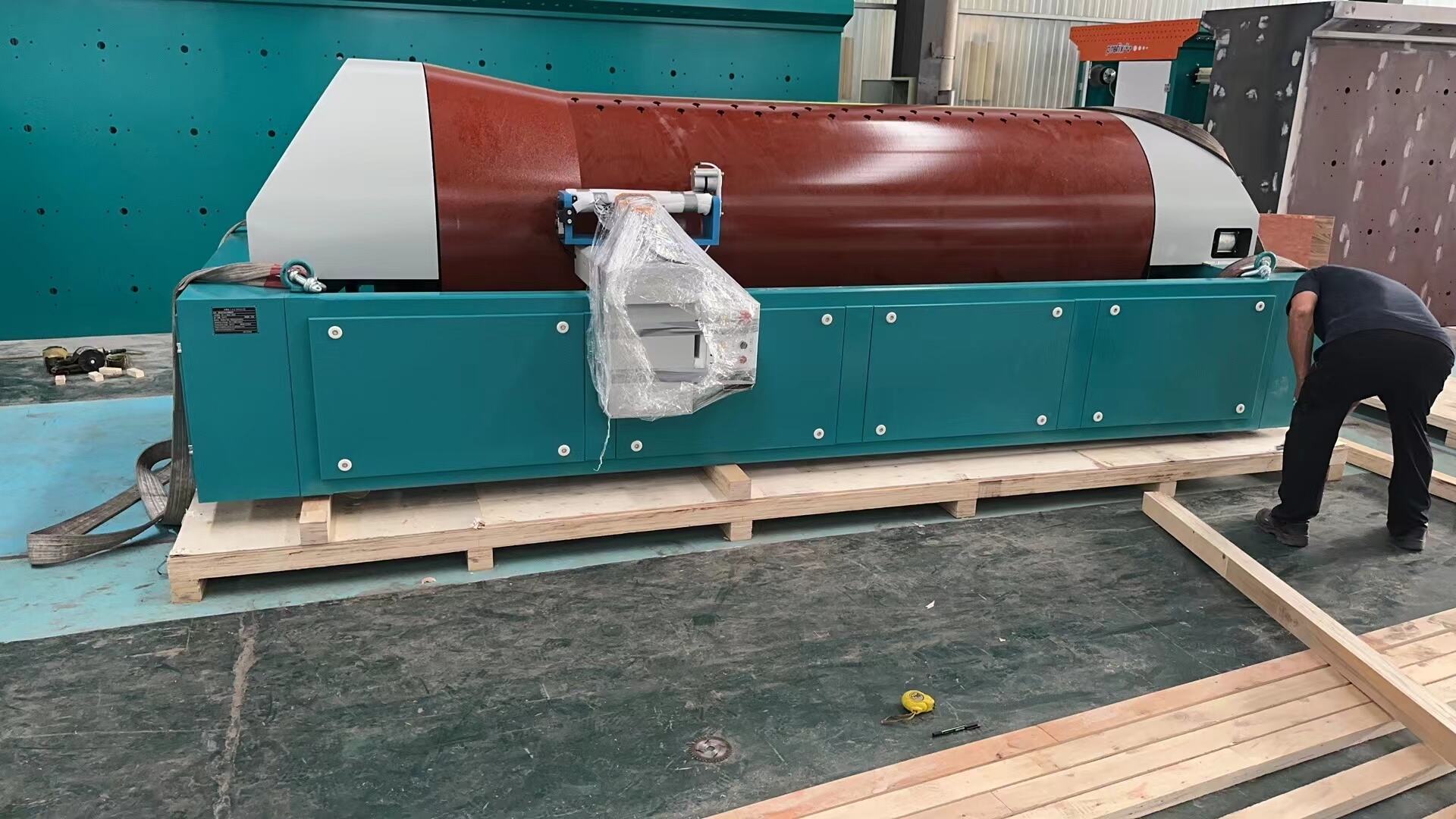

The profixM’s High-Speed Mother Yarn Warping Machine with Sectional Splitting is an independent research achievement that boasts the fastest speed and highest efficiency available on the market today. With its new condition, the machine is designed to offer unparalleled performance and precision in every aspect of its operation.

This innovative product is the perfect solution for manufacturers looking to increase their productivity and reduce production costs. The High-Speed Mother Yarn Warping Machine is equipped with the latest technology, giving it the ability to operate at speeds that are unmatched by any other machine in its class.

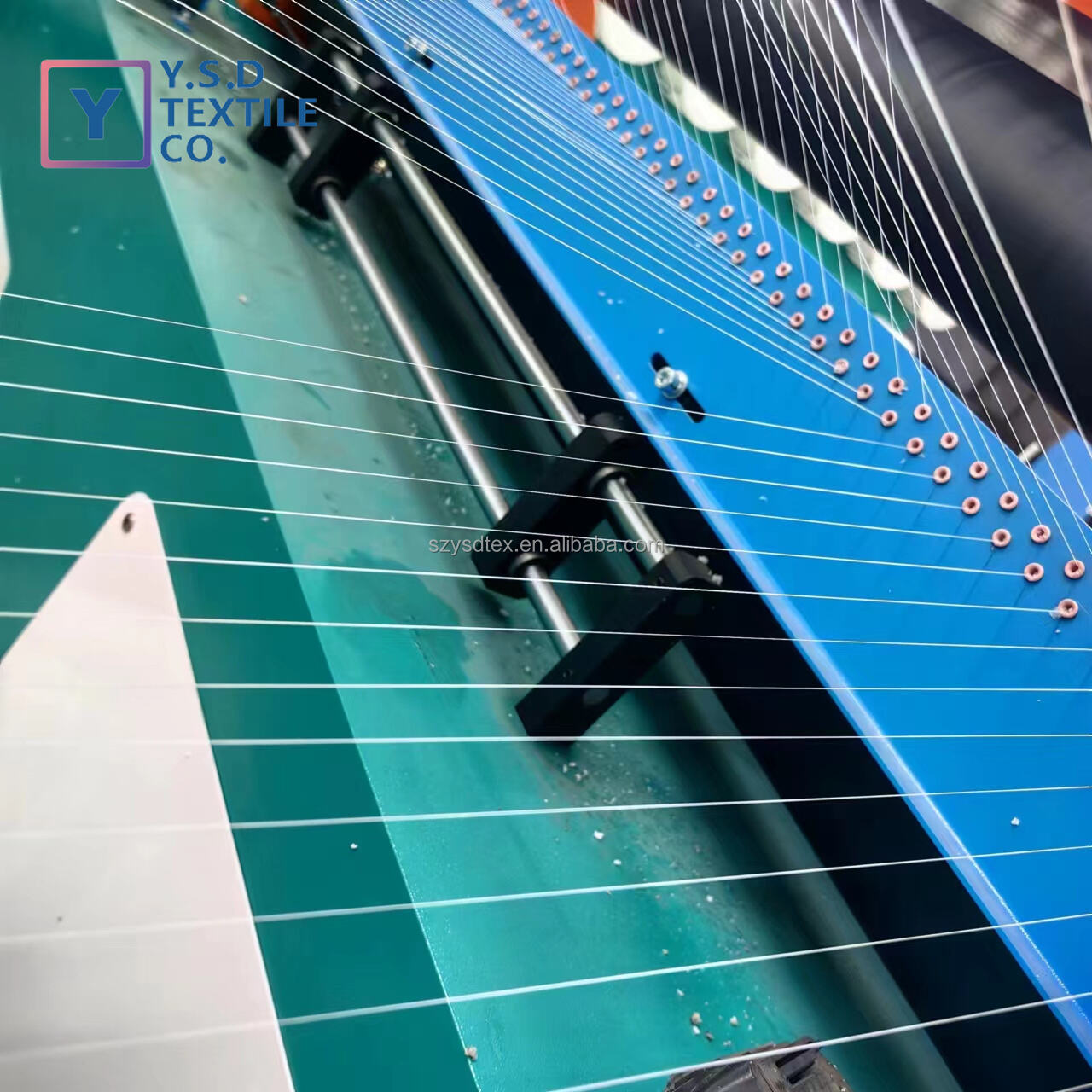

The machine features a sectional splitting function, which allows for easy and quick adjustments to the yarn tension and length. The independent research into this machine has resulted in a design that is not only fast and efficient, but also easy to use, with simple controls that make it easy to operate.

The profixM brand is known for its high-quality products, and the High-Speed Mother Yarn Warping Machine is no exception. The construction of the machine is robust, with durable materials that ensure its longevity and reliability over time. The machine is built to withstand the rigors of everyday use and is designed to require minimal maintenance, making it an ideal choice for manufacturers who need a machine that can run continuously with minimal downtime.

One of the key features of the profixM’s High-Speed Mother Yarn Warping Machine with Sectional Splitting is its exceptional speed. The machine can produce up to 2000 meters of yarn per minute, making it one of the fastest machines available on the market today. This speed, combined with the machine's efficient design, means that manufacturers can produce more yarn in less time, saving them both time and money.

In addition to its speed and efficiency, the High-Speed Mother Yarn Warping Machine is also incredibly accurate. The machine is designed to produce yarn that is consistent in both length and tension, ensuring that each and every strand is of the highest quality. This level of precision is essential for manufacturers who need to produce yarn that is uniform and consistent throughout.

The profixM’s High-Speed Mother Yarn Warping Machine with Sectional Splitting is an exceptional product that delivers unparalleled speed, efficiency, and accuracy. Its robust construction, easy-to-use controls, and low maintenance requirements make it an ideal choice for manufacturers looking to improve their productivity and reduce their production costs. For those in the textile industry, the profixM’s High-Speed Mother Yarn Warping Machine with Sectional Splitting is a must-have product

item |

value |

product |

MACHINE |

material capabilities |

NYLON/POLYESTER MOTHER YARN |

Weight (kg) |

17000 |

Machine type |

WARPING MACHINE |

Video outgoing-inspection |

Provided |

machinery test report |

Provided |

core components |

Engine |

place of origin |

China |

Jiangsu |

|

warranty |

1 Year |

Name |

SECTIONAL SPLITTING HIGH SPEED MOTHER YARN WARPING MACHINE |

Usage |

1t/day 240D/12F SD |

Warping max speed |

600m/min |

mother yarn tension |

0-500cn |

warping servo moto |

7.5kw |

beam moto |

15kw |

warp beam max speed |

250m/min |

displacement servo |

1.5kw |

Front roller servo |

5.5kw |

Back roller servo |

4.5kw |

1) The warping machine has the characteristics of high efficiency, stability, and reliability, which can greatly improve the production efficiency of the textile industry.

2) Its high precision and consistency ensure the quality of the fabric, making it more neat and uniform.

3) The warping machine is widely used in the textile industry and is one of the very important production equipment in textile factories

Q:How to place machines order

A:Please send us your purchase order by email, whatsapp or wechat. We need to know the following information for your order:

(1) Your products width and thickness(webbing, tapes, lace width and thickness)

(2) Price Item, Destination Port, Delivery time required

(3) Shipping information: Company Name, Address, Phone Number, Destination Seaport/Airport

Q:What are the payment terms

A:For orders, we can accept T/T, L/C at sight

Q:How many years of producing these machine

---We produced these machine for more than 15 years

EN

EN

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

RO

RO

RU

RU

ES

ES

ID

ID

UK

UK

VI

VI

TH

TH

TR

TR

BN

BN

NE

NE