Factory Direct High-Speed Automatic Mother Yarn Sectional Warping Machine Wide Application Equipment New Condition

- Overview

- Inquiry

- Related Products

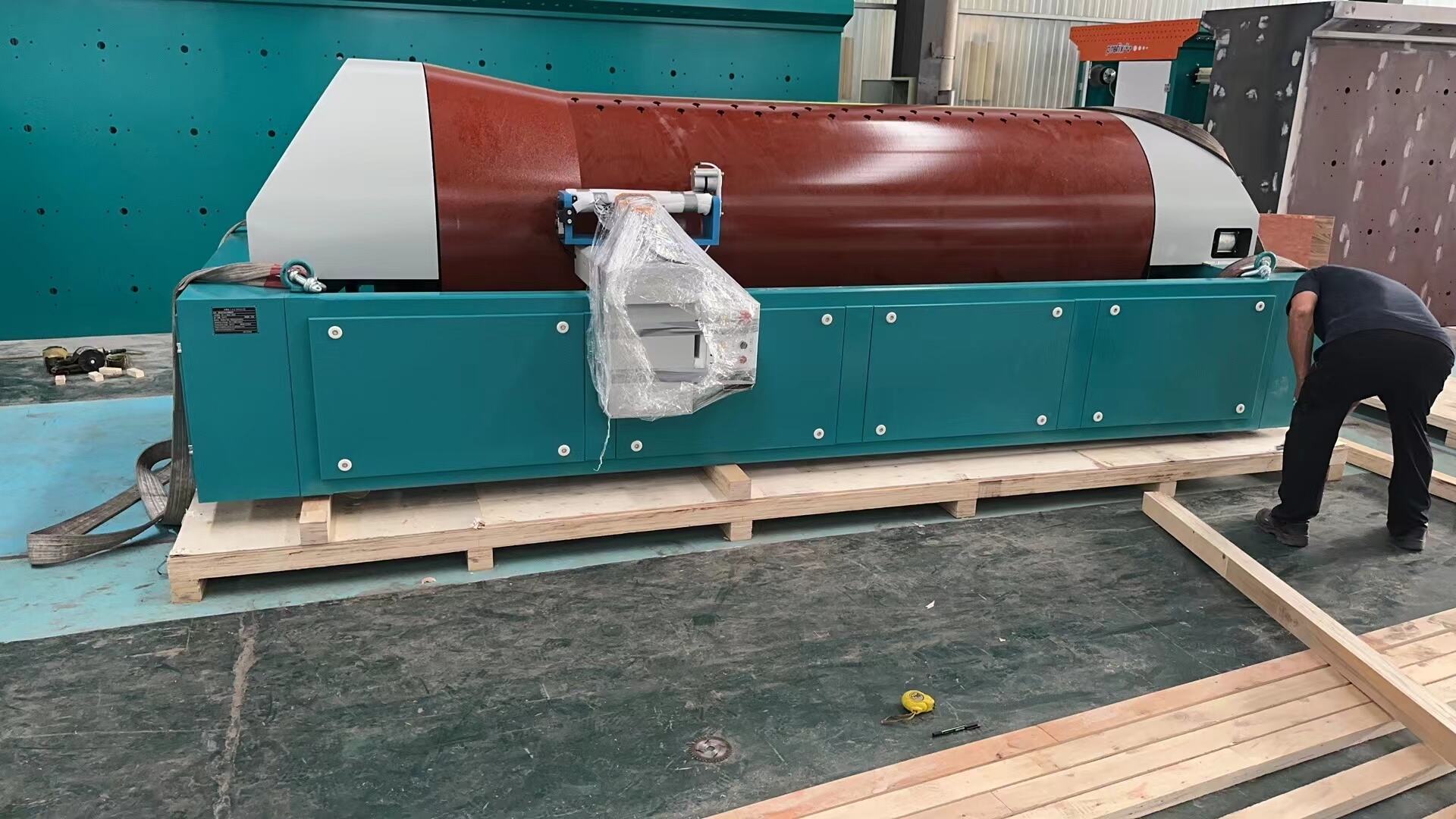

Introducing, the Factory Direct High-Speed Automatic Mother Yarn Sectional Warping Machine from profixM - the perfect solution for all of your weaving needs! This wide application equipment is in new condition, so you can be confident that it will provide you with high-quality results every time you use it.

This machine is specifically designed to work with a variety of different yarn types, making it an incredibly versatile piece of equipment for both industrial and individual use. Whether you’re working with natural fibers, synthetic materials, or a combination of both, this machine will help you create the perfect warp for your weaving project.

One of the key features of this machine is its high-speed capabilities. With automatic functionality, you can quickly and easily set up the machine and get started on your next project in no time. This is particularly helpful for those who need to process large quantities of yarn quickly and efficiently.

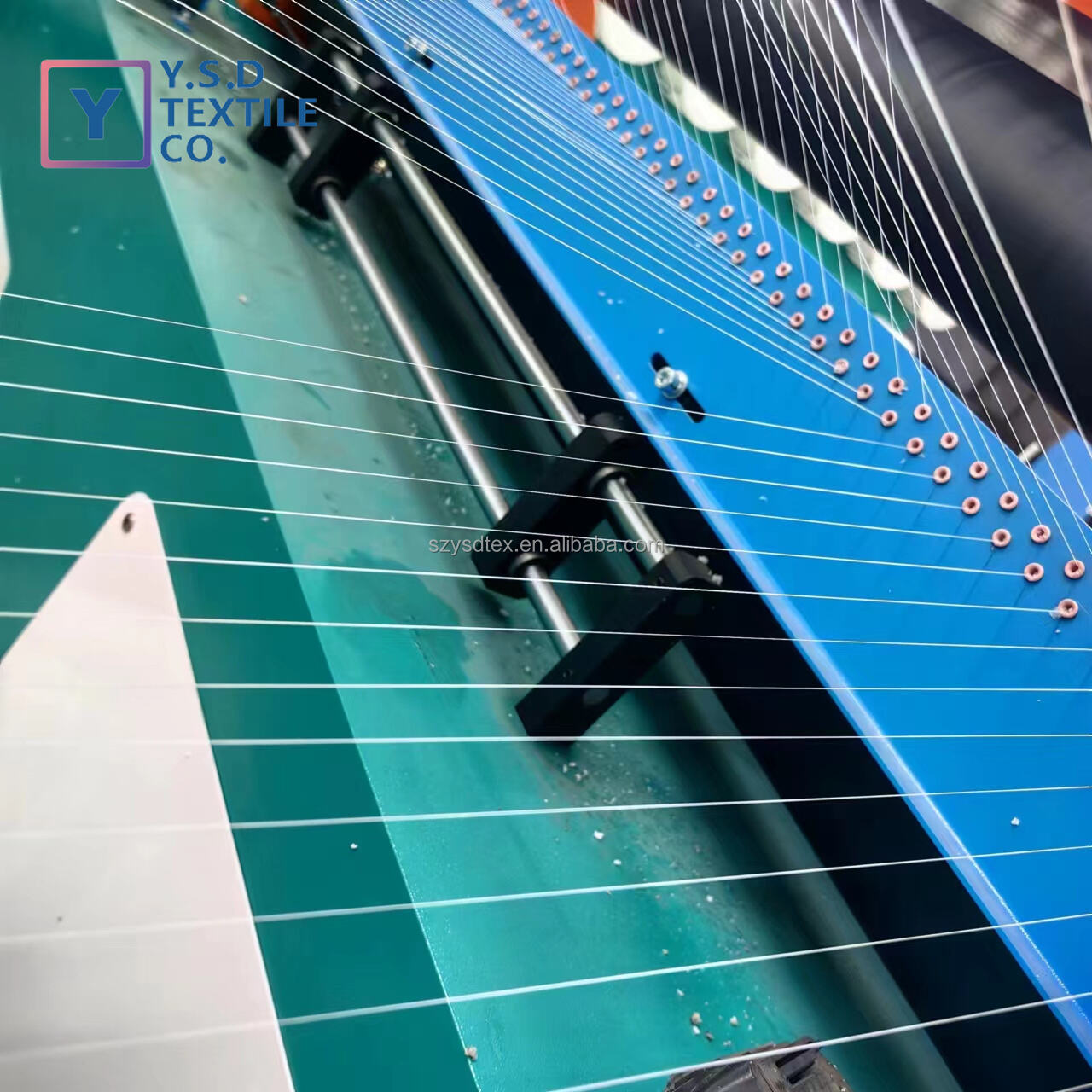

Additionally, the sectional warping method ensures that your yarn stays organized and untangled throughout the entire process. This means that you won’t have to worry about any knots or tangles getting in the way of your weaving, which will save you both time and frustration.

With its durable construction and intuitive design, the Factory Direct High-Speed Automatic Mother Yarn Sectional Warping Machine is the perfect investment for any textile enthusiast or professional weaver. Whether you’re just starting out in the world of weaving or you’re a seasoned veteran, this machine offers an unparalleled level of reliability, efficiency, and ease-of-use.

So, if you’re looking for a high-quality, versatile weaving machine that will help you take your textile creations to the next level, look no further than profixM’s Factory Direct High-Speed Automatic Mother Yarn Sectional Warping Machine. Order yours today and start experiencing the benefits of this amazing equipment for yourself

item |

value |

||||||

Applicable Industries |

Manufacturing Plant |

||||||

Name |

SECTIONAL MOTHER YARN SPLITTING WARPING MACHINE |

||||||

Video outgoing-inspection |

Provided |

||||||

Machinery Test Report |

Provided |

||||||

Marketing Type |

New Product 2025 |

||||||

Warranty of core components |

1 Year |

||||||

Place of Origin |

China, Jiangsu |

||||||

Machine Type |

WARPING MACHINE |

||||||

Material Capabilities |

NYLON/ POLYESTER FDY/ DTY MOTHER YARN |

||||||

Condition |

New |

||||||

Weight (KG) |

17000 |

||||||

Yarn Usage |

1t/day 240D/12F SD |

||||||

Warping max speed |

600m/min ON 240/12 SD NYLON MOTHER YARN |

||||||

warping servo moto |

7.5kw |

||||||

beam moto |

15kw |

||||||

warp beam max speed |

180m/min |

||||||

displacement servo |

1.5kw |

||||||

Front roller servo |

5.5kw |

||||||

Back roller servo |

4.5kw |

||||||

1) The warping machine has the characteristics of high efficiency, stability, and reliability, which can greatly improve the production efficiency of the textile industry.

2) Its high precision and consistency ensure the quality of the fabric, making it more neat and uniform.

3) The warping machine is widely used in the textile industry and is one of the very important production equipment in textile factories

Q:How to place machines order

A:Please send us your purchase order by email, whatsapp or wechat. We need to know the following information for your order:

(1) Your products width and thickness (webbing, tapes, lace width and thickness)

(2) Price Item, Destination Port, Delivery time required

(3) Shipping information: Company Name, Address, Phone Number, Destination Seaport/Airport

Q:What are the payment terms

A:For orders, we can accept T/T, L/C at sight

Q:How many years of producing these machine

---We produced these machine for more than 15 years

EN

EN

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

RO

RO

RU

RU

ES

ES

ID

ID

UK

UK

VI

VI

TH

TH

TR

TR

BN

BN

NE

NE