Automatic Customizable Size Textile Machine High-Automatic Section Split FDY DTY Mother Yarn Warping Machine

- Overview

- Inquiry

- Related Products

ProfixM

Introducing the incredible Automatic Customizable Size Textile Machine, the High-Automatic Section Split FDY DTY Mother Yarn Warping Machine that takes textile manufacturing to a whole new level.

This machine is designed to make the process of textile production easier, faster, and customizable to cater to the individual needs of different manufacturing workshops. Its automatic feature allows for a high level of output while maintaining quality and consistency in the textiles produced.

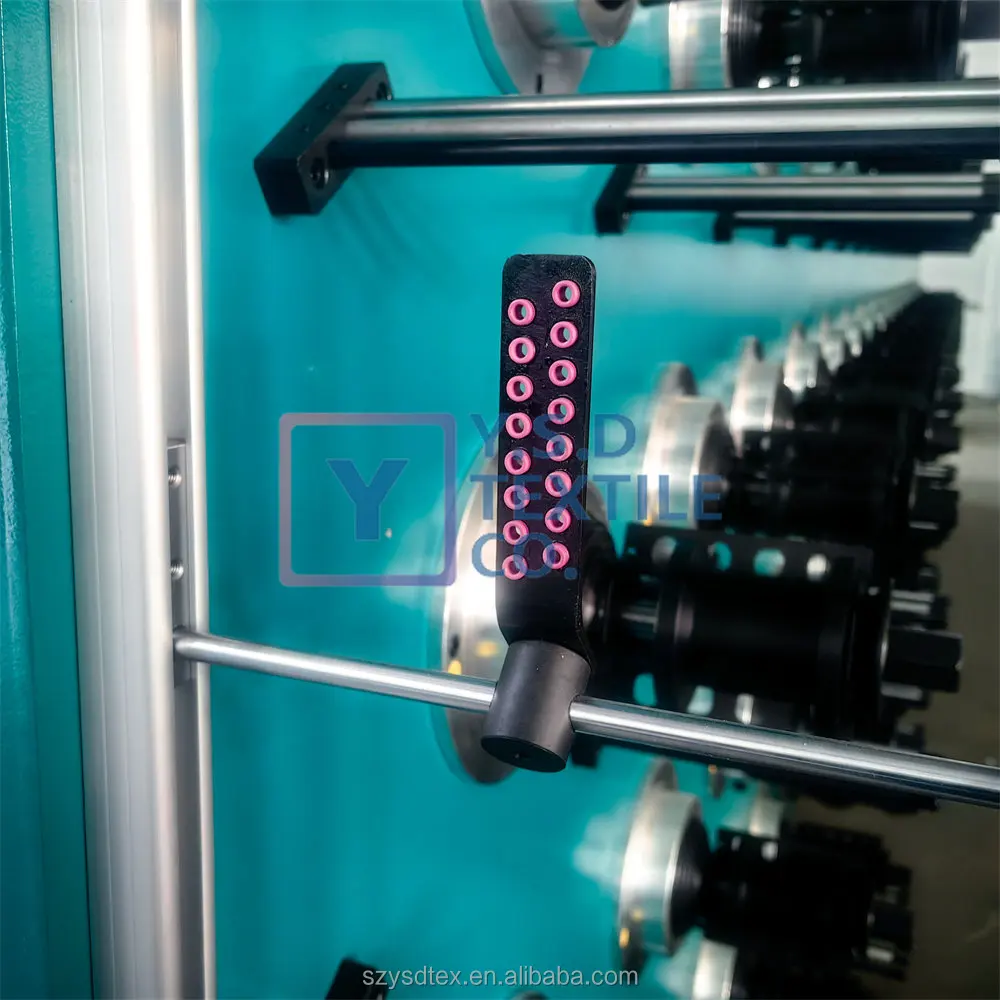

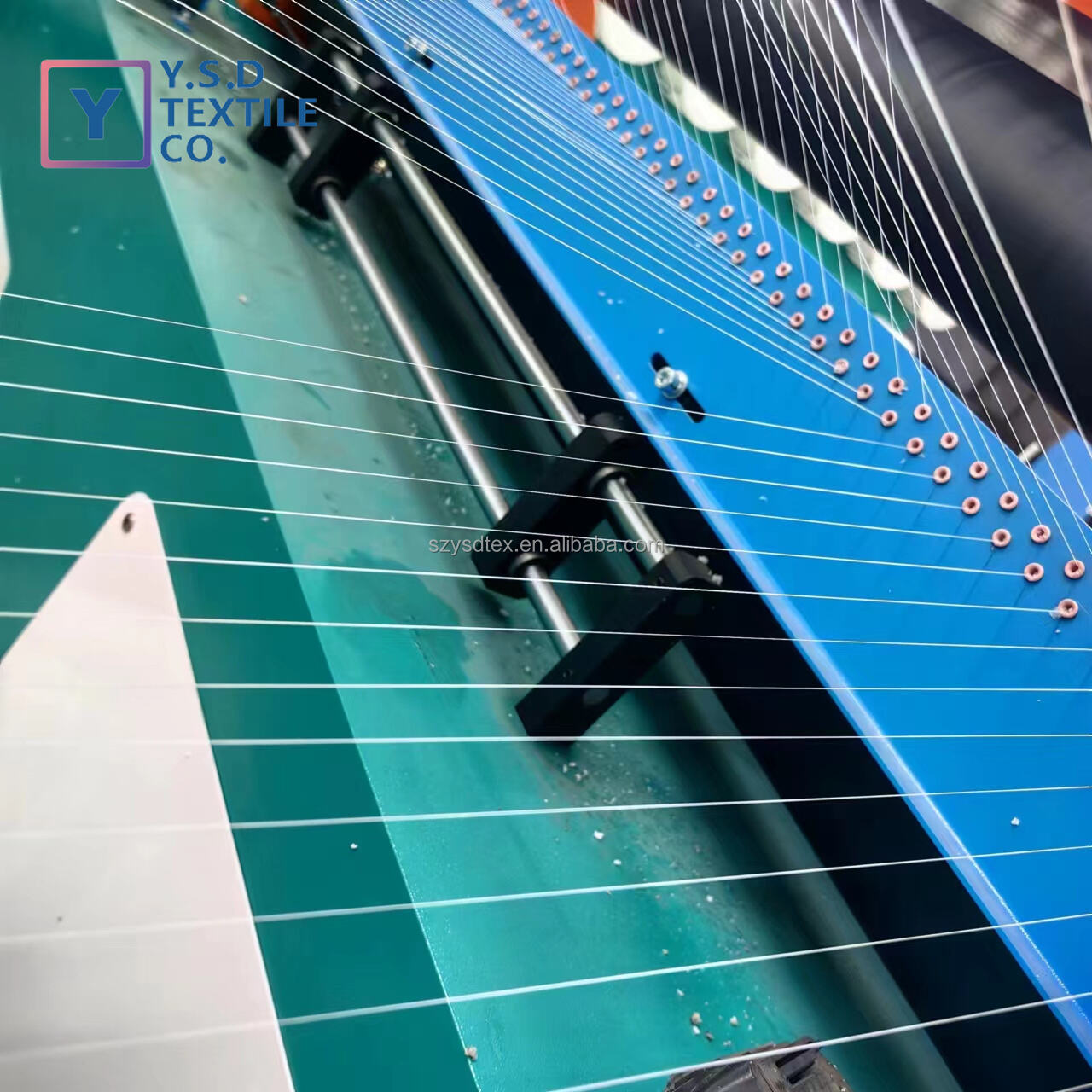

One of the unique features of this machine is that it is capable of section splitting FDY and DTY mother yarn. This means that it can take a single mother yarn and divide it into multiple sections to produce different types of textiles. This feature is particularly useful in large-scale manufacturing where the need to produce different types of textiles is high.

Moreover, the Automatic Customizable Size Textile Machine can warp fabrics of varying sizes, making it a versatile machine for textile manufacturers. The profixM customizable sizing feature allows manufacturers to produce textiles of different lengths and widths using a single machine, making it cost-effective for small-scale and large-scale production alike.

The high automation feature of this machine enables it to function with minimal human intervention. This not only reduces the likelihood of human error but also increases the efficiency and speed of production. The machine's user-friendly interface and easy-to-use controls allow for easy operation, making it easy for even those unfamiliar with textile manufacturing to use.

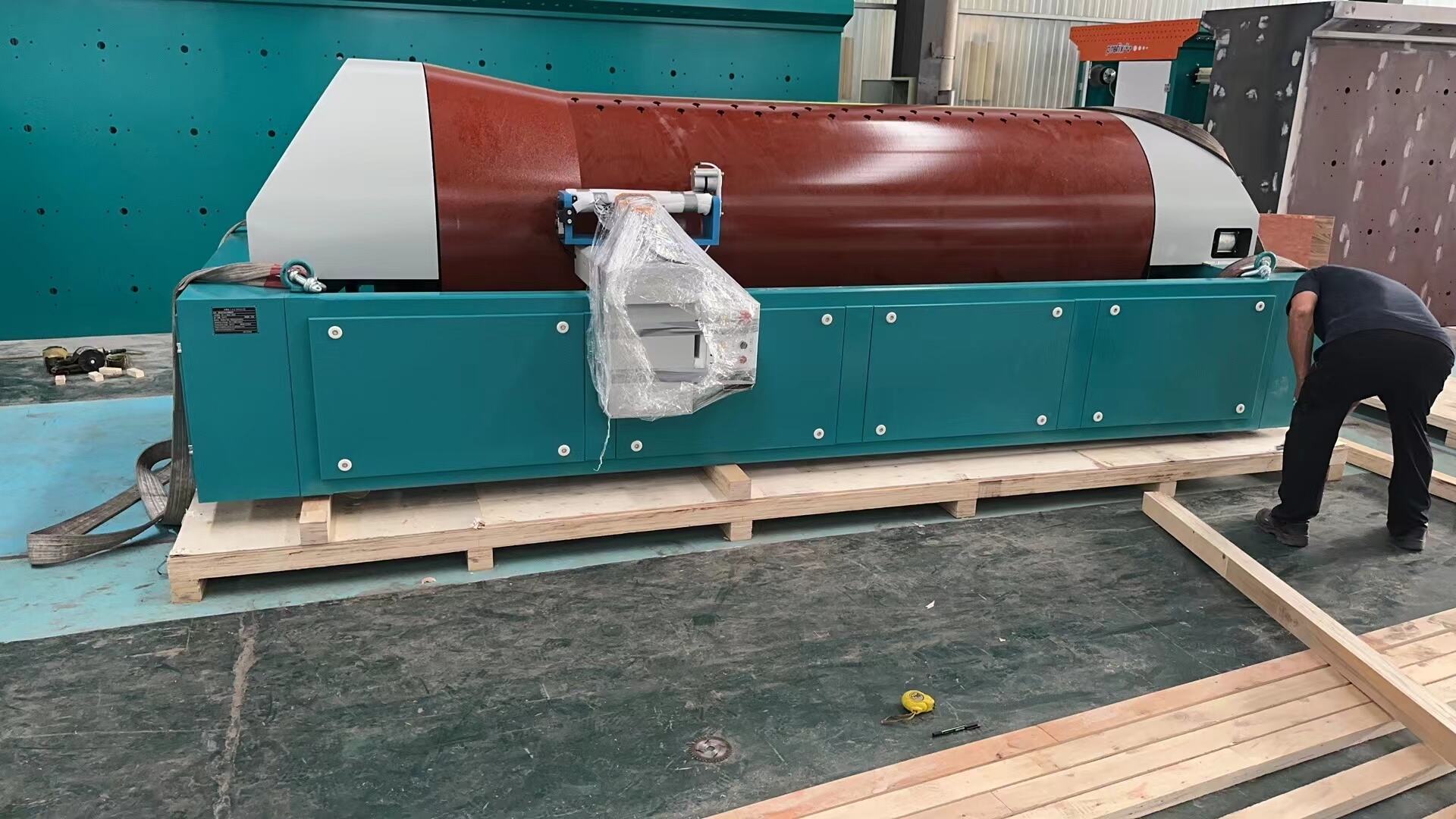

In terms of design and construction, profixM has ensured that this machine is built to last. The materials used in its construction are of high quality, ensuring durability and longevity. The machine is also easy to maintain and requires minimal upkeep, which translates to less downtime and increased productivity.

the Automatic Customizable Size Textile Machine from profixM is a game-changer in the textile manufacturing industry. Its high degree of automation, customizable sizing, and section splitting features make it an ideal solution for textile manufacturers looking to increase productivity, reduce costs and improve the quality of their output. With this machine, you can be assured of quality, consistency, and reliability in your production process. Get yours today and take your textile production to a whole new level.

item |

value |

product |

MACHINE |

material capabilities |

NYLON/POLYESTER MOTHER YARN |

weight (kg) |

17000 |

machine type |

WARPING MACHINE |

video outgoing-inspection |

Provided |

machinery test report |

Provided |

core components |

Engine |

place of origin |

China |

Jiangsu |

|

warranty |

1 Year |

Name |

sectional nylon polyester mother yarn splitting warping machine |

Usage |

1t/day 240D/12F SD |

Warping max speed |

600m/min |

mother yarn tension |

0-500cn |

warping servo moto |

7.5kw |

beam moto |

15kw |

warp beam max speed |

250m/min |

displacement servo |

1.5kw |

Front roller servo |

5.5kw |

Back roller servo |

4.5kw |

EN

EN

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

RO

RO

RU

RU

ES

ES

ID

ID

UK

UK

VI

VI

TH

TH

TR

TR

BN

BN

NE

NE