Automatic Customizable Size Textile Machine High-Automatic Sectional Split FDY DTY Mother Yarn Warping Machine

- Overview

- Inquiry

- Related Products

Introducing, the high-performance and versatile Automatic Customizable Size Textile Machine from profixM that promises to revolutionize the way textile manufacturing takes place. This machine is specially designed to cater to the needs of modern textile manufacturers who are looking for ways to boost their productivity and improve their product quality.

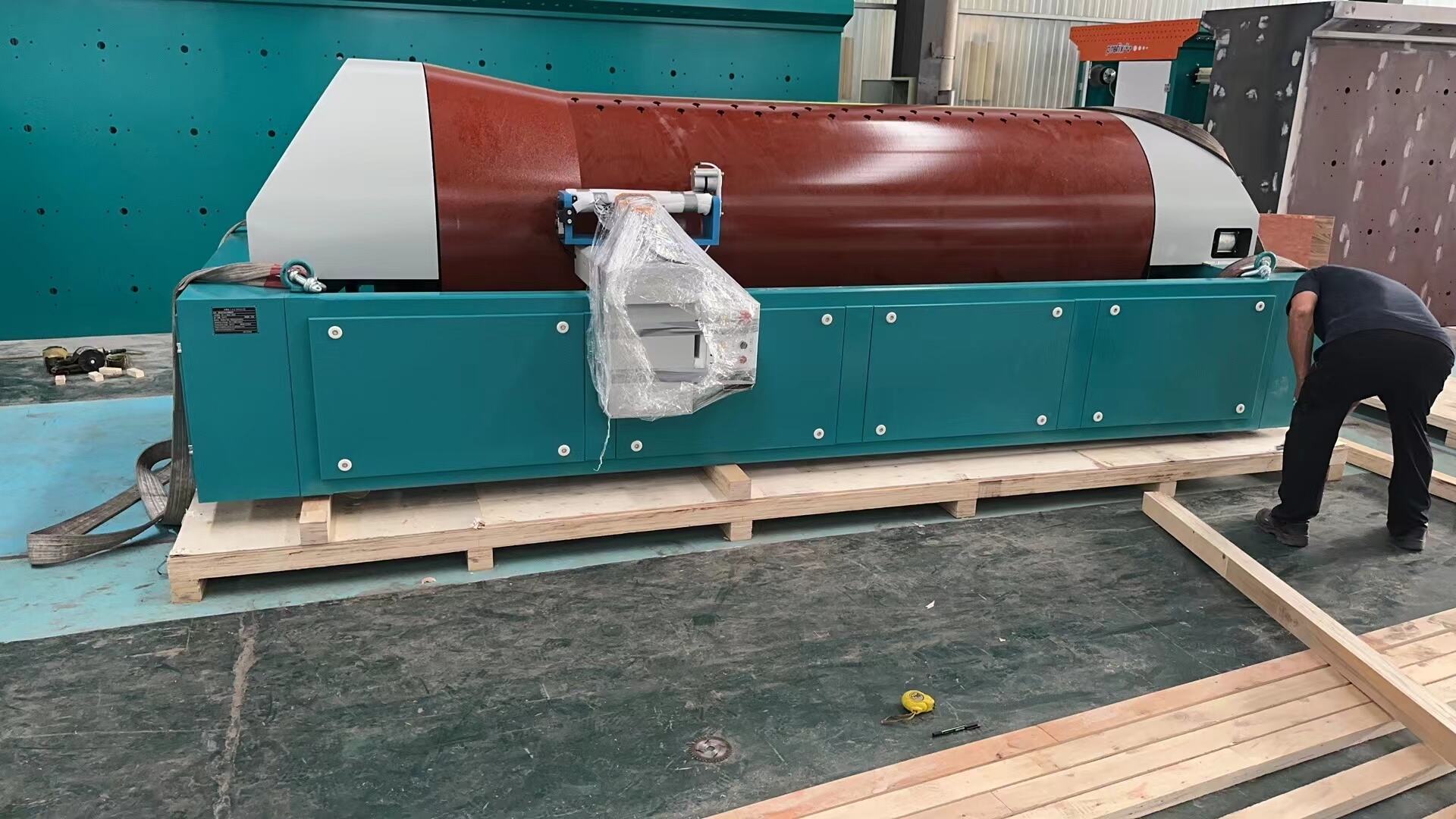

With its innovative design, the Automatic Customizable Size Textile Machine offers unmatched versatility, allowing it to handle a wide range of materials and produce a variety of high-quality fabrics. This machine is particularly suited for the production of FDY (Fully Drawn Yarn) and DTY (Drawn Textured Yarn) Mother Yarn, which are key components in manufacturing various textiles such as clothing, bedding, and upholstery.

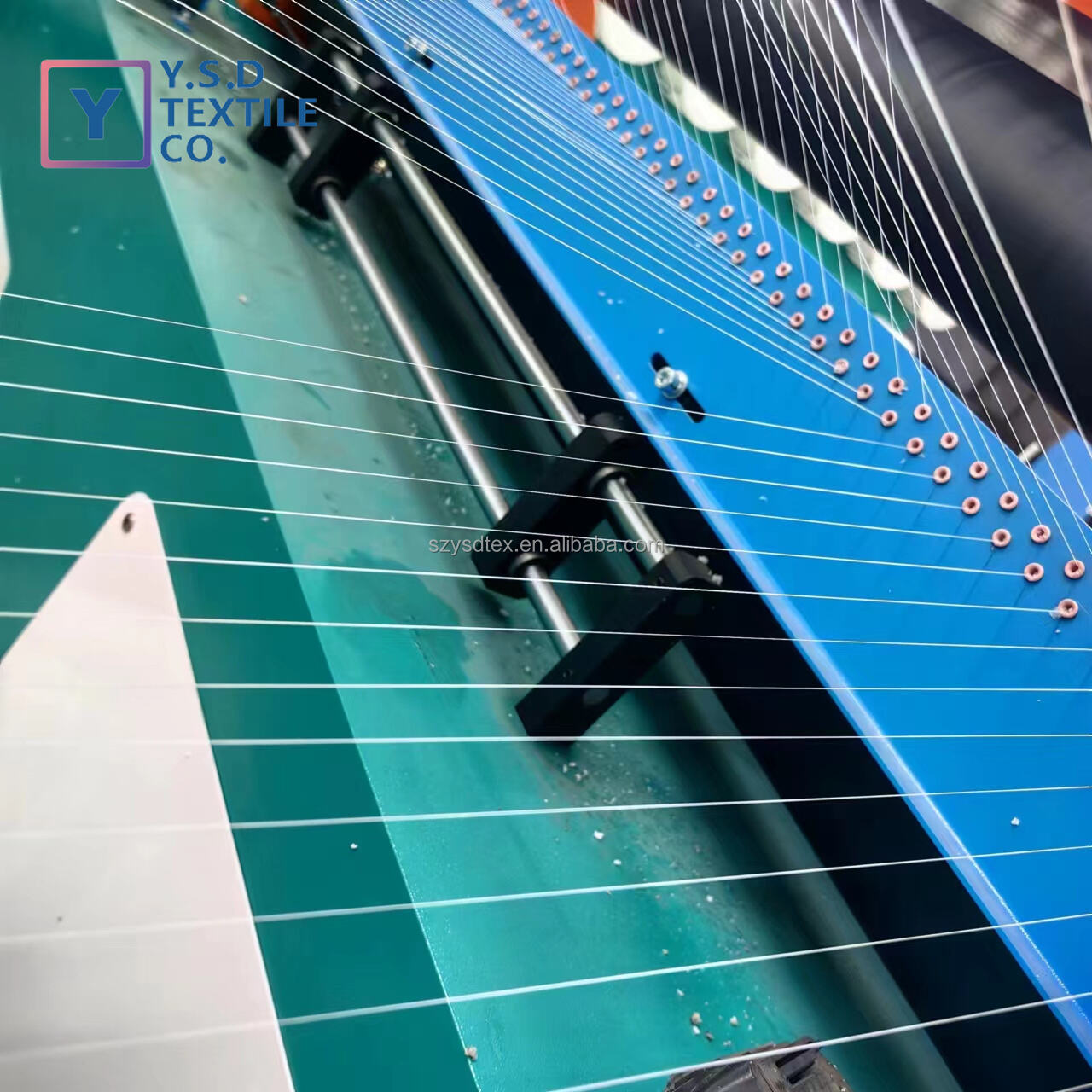

The machine features a high level of automation, which makes it easy and efficient to operate. Additionally, it has a sectional split design that allows it to produce a range of sizes and configurations of fabric. This makes it highly adaptable, and enables manufacturers to produce custom-sized textiles to meet the specific demands of their customers.

One of the most impressive features of the Automatic Customizable Size Textile Machine is its high level of precision. It produces fabrics that are of a consistent quality and uniform thickness, which is essential for textile manufacturers who want to create products that meet the highest standards of quality.

Another notable feature of this machine is its user-friendly interface. Operators can easily control and adjust the machine through its intuitive and interactive interface, which features a touch screen display. This makes it easy to monitor the machine's performance and make necessary adjustments to ensure optimal results.

The Automatic Customizable Size Textile Machine is also designed with energy efficiency in mind. It uses the latest technology to minimize energy consumption, making it an eco-friendly choice for manufacturers who are committed to sustainable production practices. Moreover, its durable construction ensures longevity, minimizing maintenance costs and downtime.

profixM's Automatic Customizable Size Textile Machine is an innovative and high-performance solution for modern textile manufacturers. Its versatility, precision, automation, and energy efficiency make it a reliable and cost-effective option for those looking to improve their production capabilities. With this machine, textile manufacturers can stay ahead of the competition and meet the ever-evolving needs of their customers

item |

value |

product |

MACHINE |

material capabilities |

NYLON/POLYESTER MOTHER YARN |

Weight (kg) |

13500 |

machine type |

WARPING MACHINE |

Video outgoing-inspection |

Provided |

machinery test report |

Provided |

core components |

Engine |

Place of origin |

China |

Jiangsu |

|

warranty |

1 Year |

Name |

sectional nylon polyester mother yarn splitting warping machine |

Usage |

1t/day 240D/12F SD |

Warping max speed |

600m/min |

mother yarn tension |

0-500cn |

warping servo moto |

7.5kw |

beam moto |

15kw |

warp beam max speed |

180m/min |

displacement servo |

1.5kw |

Front roller servo |

5.5kw |

Back roller servo |

4.5kw |

1) The warping machine has the characteristics of high efficiency, stability, and reliability, which can greatly improve the production efficiency of the textile industry.

2) Its high precision and consistency ensure the quality of the fabric, making it more neat and uniform.

3) The warping machine is widely used in the textile industry and is one of the very important production equipment in textile factories

Q:How to place machines order

A:Please send us your purchase order by email, whatsapp or wechat. We need to know the following information for your order:

(1) Your products width and thickness(webbing, tapes, lace width and thickness)

(2) Price Item, Destination Port, Delivery time required

(3) Shipping information: Company Name, Address, Phone Number, Destination Seaport/Airport

Q:What are the payment terms

A:For orders, we can accept T/T, L/C at sight

Q:How many years of producing these machine

---We produced these machine for more than 15 years

EN

EN

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

RO

RO

RU

RU

ES

ES

ID

ID

UK

UK

VI

VI

TH

TH

TR

TR

BN

BN

NE

NE