- Overview

- Inquiry

- Related Products

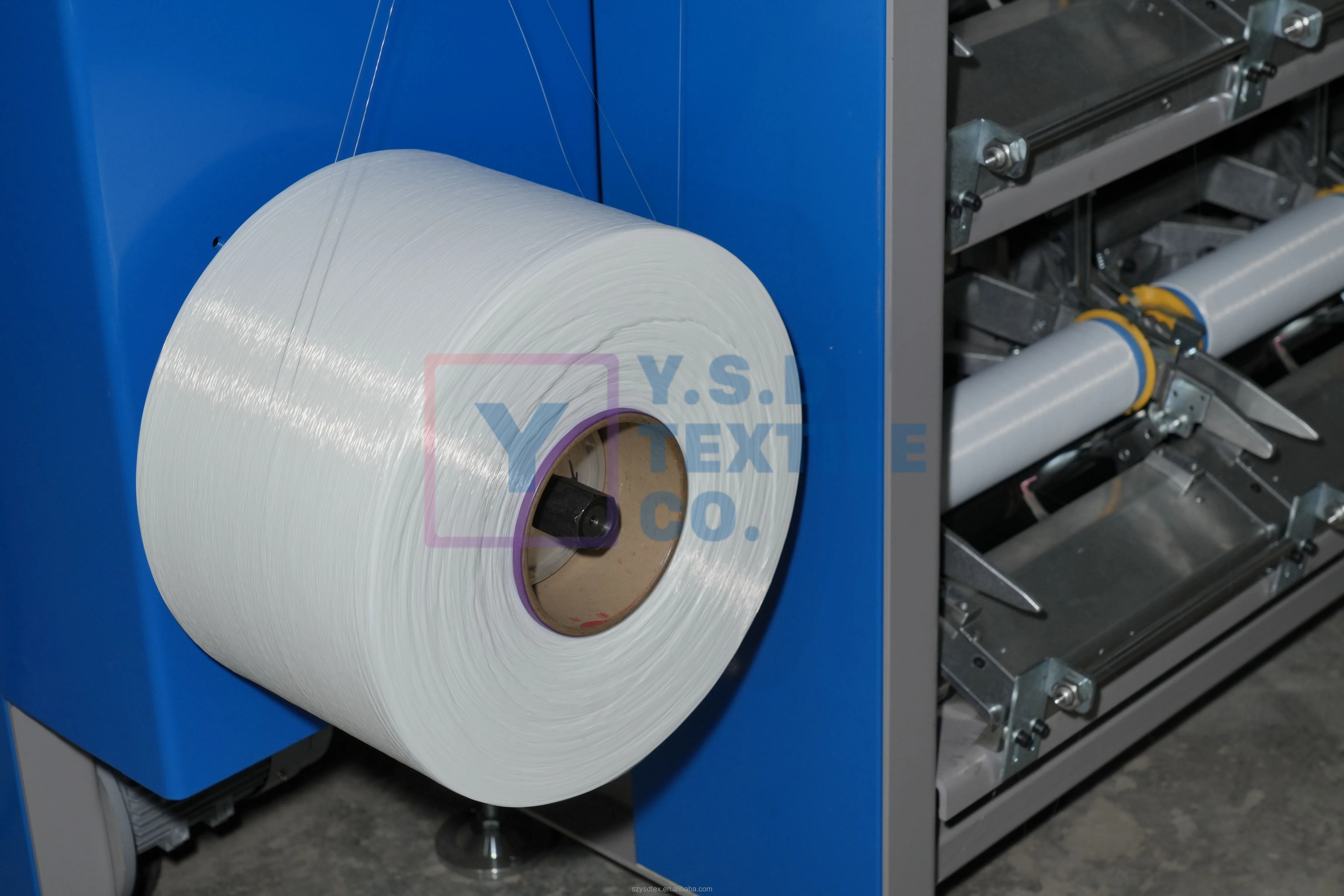

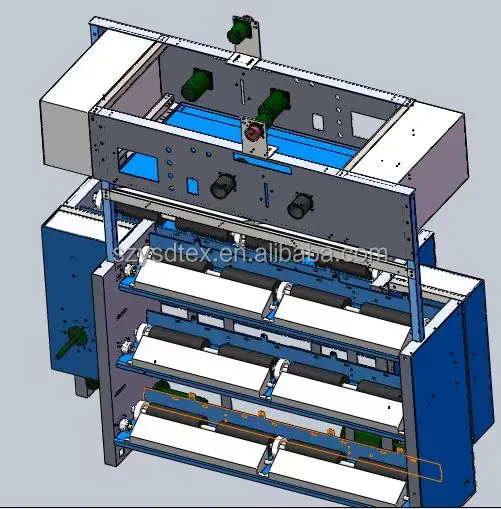

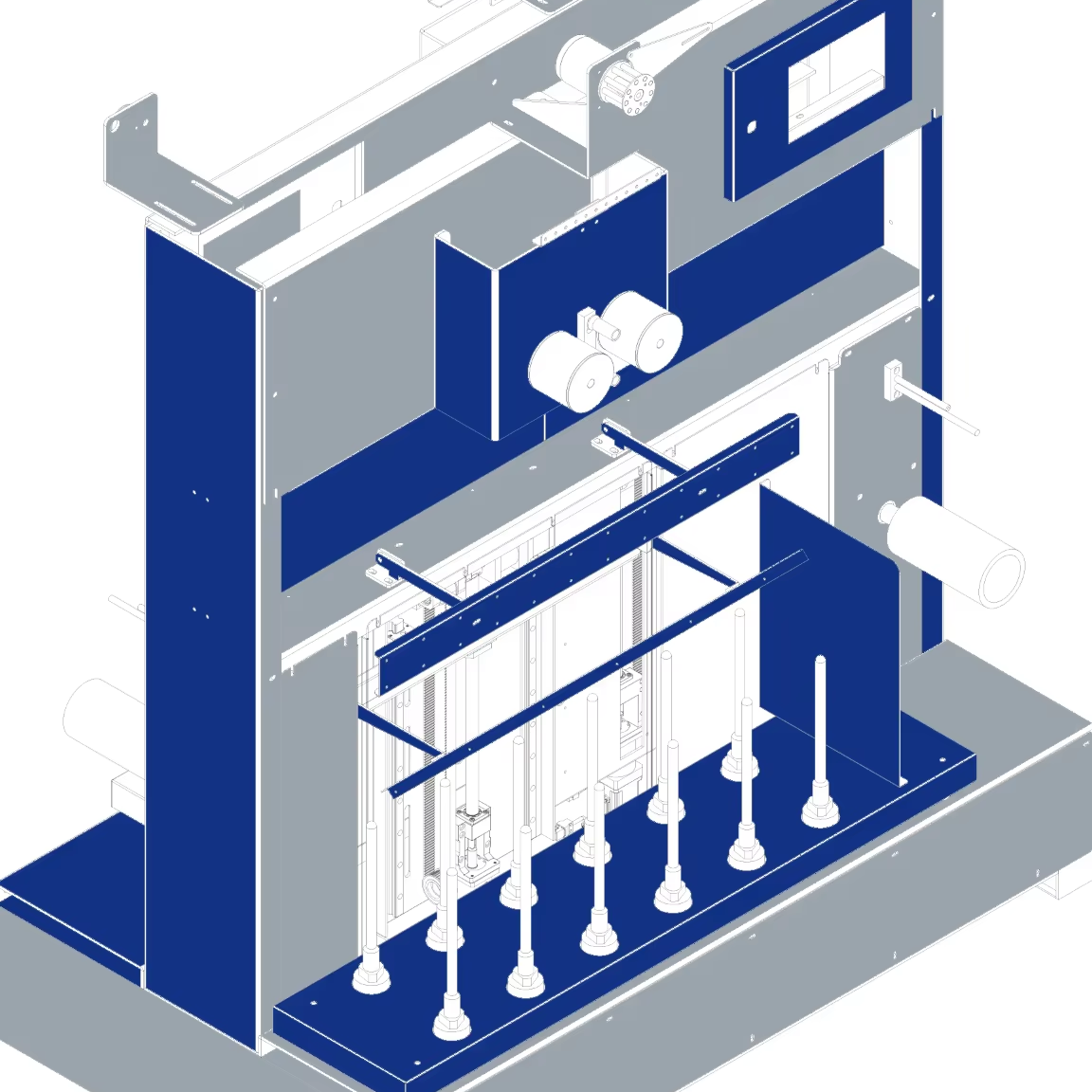

The high-automatic Mother Yarn Splitting Machine from profixM is a game-changer for the textile industry. With its advanced features, it provides efficient rolling on paper tube that saves both time and money.

This machine is great for manufacturers who produce large quantities of yarn as it can handle a huge workload. Its high automation ensures a smooth and fast process, resulting in a more productive work environment. It’s easy to operate, so even those new to the industry will find it user-friendly.

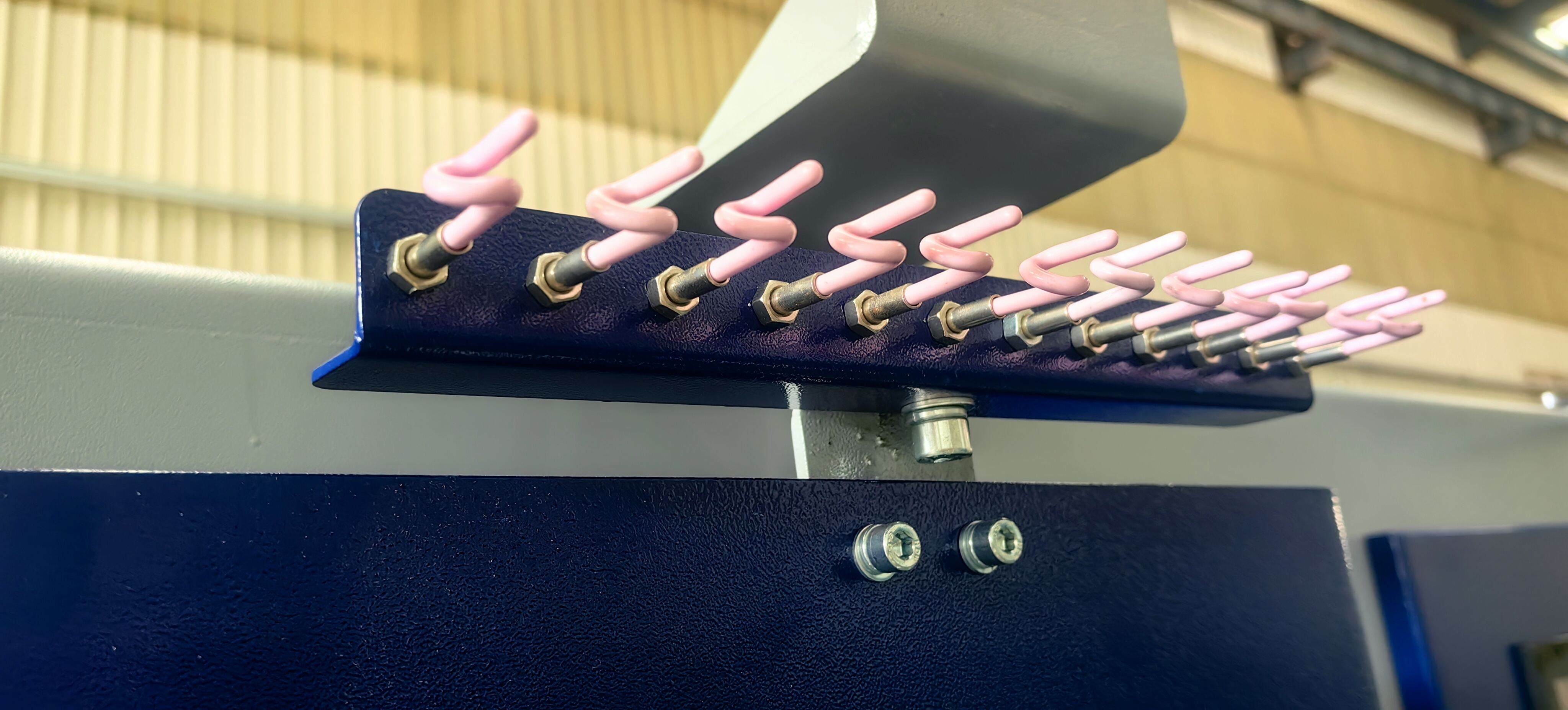

The Mother Yarn Splitting Machine has a unique yarn splitting mechanism which allows for even winding. The tension control system ensures uniform tension throughout the winding process. This feature, combined with its high speed, means that no yarn is over-stretched or breaks during winding. This ultimately results in better quality products with fewer defects.

This machine also comes with an automatic yarn length monitoring system which ensures that the yarn is loaded and wound onto the paper tube evenly. You can set the required length of yarn before the automatic winding process begins. This feature reduces wastage as it ensures that only the required length of yarn is wound onto the paper tube. It also ensures consistency in the length of the yarn produced.

One of the best things about the Mother Yarn Splitting Machine is that it is designed with cutting-edge technology. Its sensors can detect any foreign objects that may be in the yarn, such as a piece of cloth or plastic. Once detected, it automatically stops the winding process to prevent any damage to the machine or the yarn.

Lastly, the Mother Yarn Splitting Machine from profixM is also designed to be energy-efficient. Its motor and transmission system are carefully engineered to reduce energy consumption. This feature is great for companies looking to reduce their carbon footprint and operating costs.

The Mother Yarn Splitting Machine from profixM is a must-have for textile manufacturers looking for efficient and high-quality yarn production. Its advanced features not only save time and money, but they also ensure top-notch quality products. Get yours today and take your textile manufacturing to the next level

item |

value |

product |

Machine |

material capabilities |

Nylon and polyester mono yarn |

Weight (kg) |

600 |

machine type |

Mother yarn splitting machine |

Video outgoing-inspection |

Provided |

machinery test report |

Provided |

core components |

Engine |

place of origin |

China |

Jiangsu |

|

warranty |

1 Year |

Name |

Mother yarn splitting machine |

Winding coil skeleton |

95-130x230mm |

Splitting tension |

0.6g/d- 1.0g/d |

Winding |

120*2300mm |

splitting speed |

200D/10F can reach 800/min |

Forming device |

100mm-460mm |

Spindle motor |

1kw |

Wire feed motor |

0.24kw |

Forming motor |

0.02kw |

Spitting motor |

0.02kw |

Q:How to place machines order

A:Please send us your purchase order by email, whatsapp or wechat. We need to know the following information for your order:

(1) Your products width and thickness(webbing, tapes, lace width and thickness)

(2) Price Item, Destination Port, Delivery time required

(3) Shipping information: Company Name, Address, Phone Number, Destination Seaport/Airport

Q:What are the payment terms

A:For orders, we can accept T/T, L/C at sight

Q:How many years of producing these machine?

---We produced these machine for more than 15 years

EN

EN

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

RO

RO

RU

RU

ES

ES

ID

ID

UK

UK

VI

VI

TH

TH

TR

TR

BN

BN

NE

NE