High-Automatic Section Split FDY DTY Mother Yarn Warping Machine New Condition for Manufacturing Plant

- Overview

- Inquiry

- Related Products

ProfixM

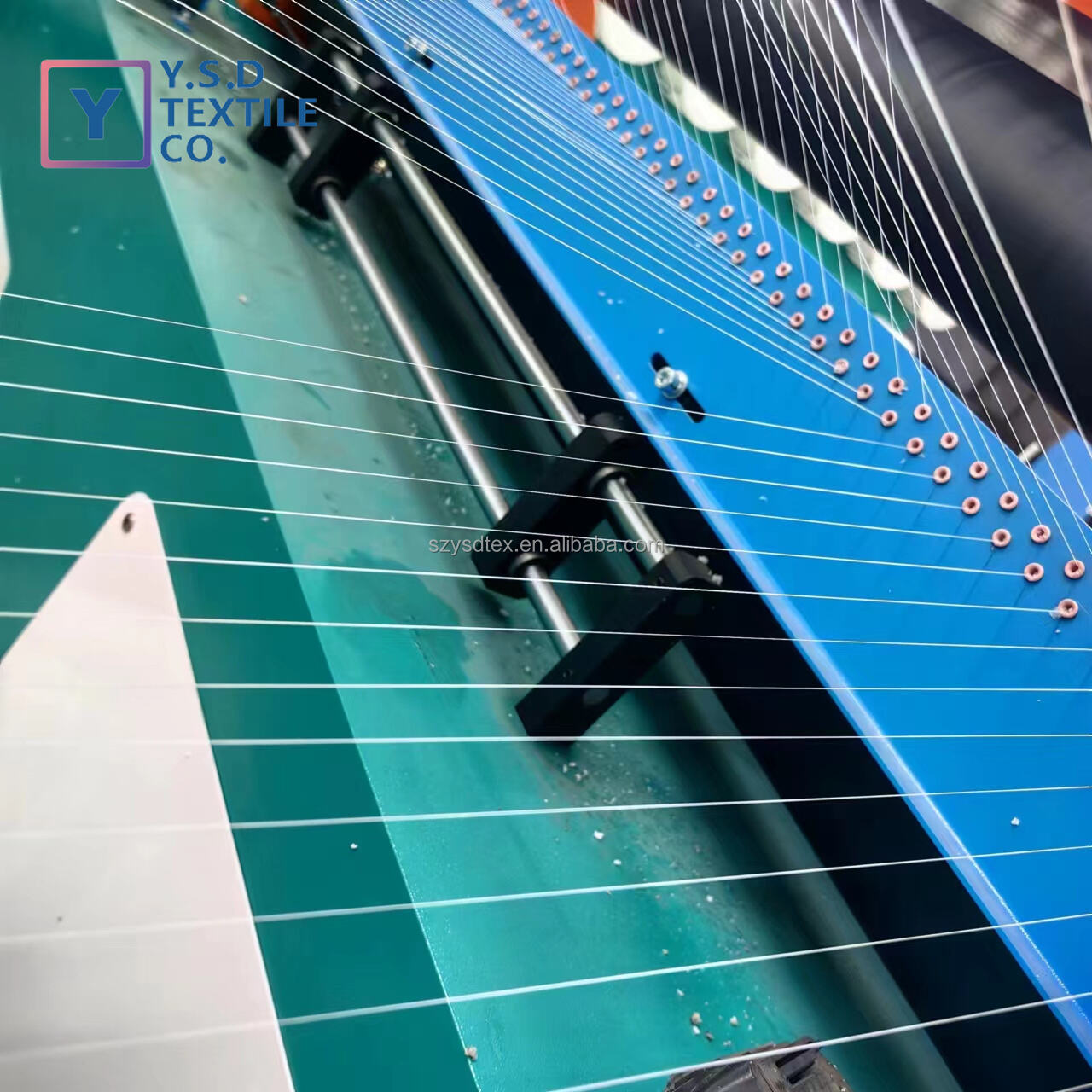

The High-Automatic Section Split FDY DTY Mother Yarn Warping Machine is a top-of-the-line offering that is ideal for manufacturing plants that require high-quality, efficient yarn warping. The machine is designed to handle both FDY and DTY mother yarn, ensuring that it is highly versatile and can be used for a range of different applications.

The High-Automatic Section Split FDY DTY Mother Yarn Warping Machine is incredibly user-friendly and easy to operate, meaning that it is suitable for use by both experienced technicians and those who are new to the industry. The machine features a range of adjustable settings and options, meaning that it can be easily customized to meet the specific needs of different applications.

One of the key benefits of the High-Automatic Section Split profixM FDY DTY Mother Yarn Warping Machine is its high level of automation. This means that the machine is able to perform a range of complex operations with minimal human input, ensuring that it is highly efficient and productivity levels are maximized.

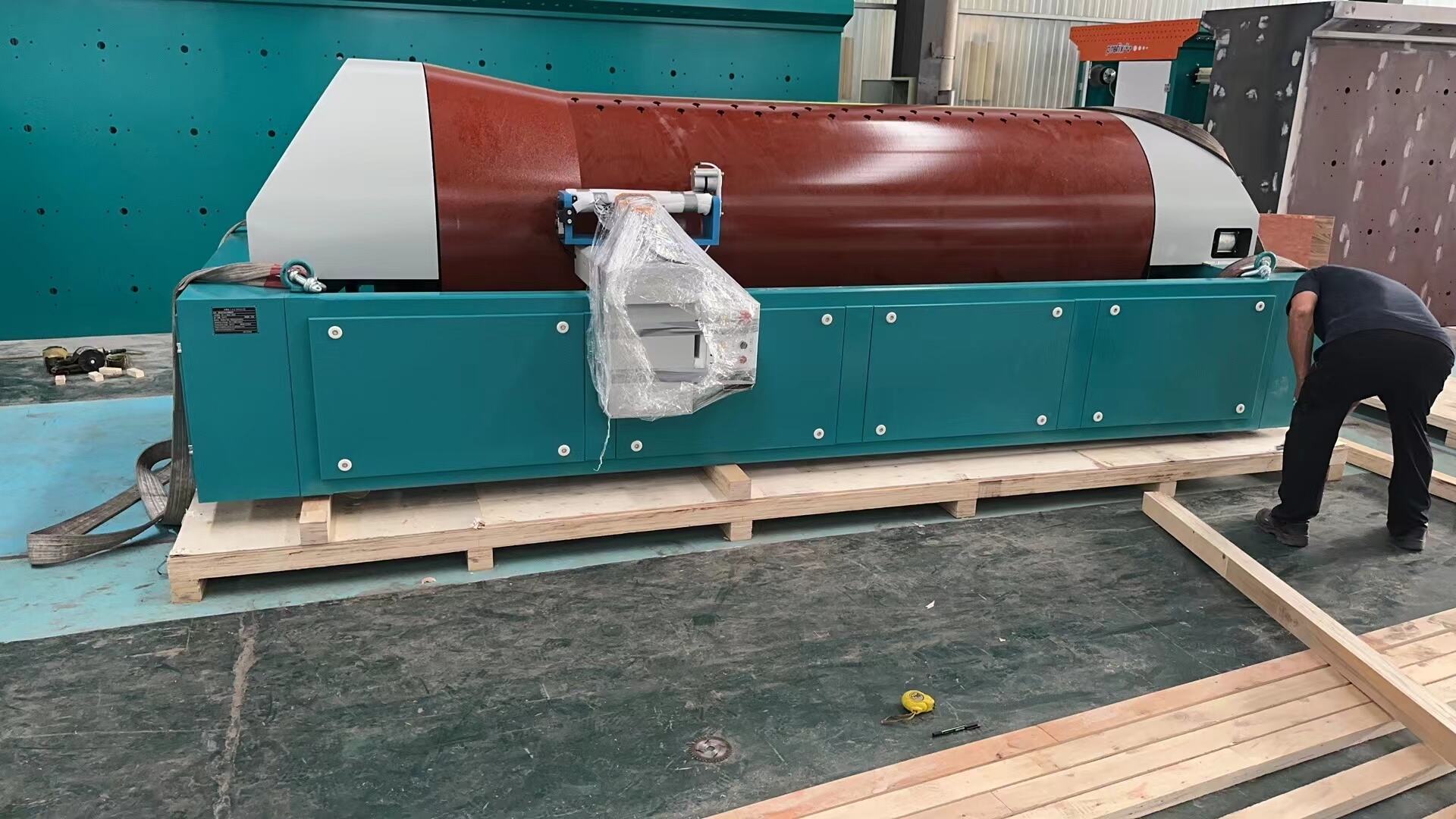

In addition to its high level of automation, the machine is also highly reliable and durable, meaning that it can be relied on to perform consistently over long periods of time. This is particularly important for manufacturing plants that require high levels of output and need to ensure that their equipment is able to withstand heavy use.

The High-Automatic Section Split FDY DTY Mother Yarn Warping Machine is also incredibly easy to maintain, meaning that downtime is minimized and production levels are maintained at all times. The machine features a range of user-friendly maintenance options and can be easily serviced by trained technicians.

The profixM High-Automatic Section Split FDY DTY Mother Yarn Warping Machine is a reliable, efficient and highly versatile piece of equipment that is ideal for a range of different manufacturing applications. It is suitable for use by both experienced technicians and those who are new to the industry, and its high level of automation ensures that productivity levels are maximized at all times. With its range of adjustable settings and easy-to-use maintenance options, this machine is a must-have for any manufacturing plant that requires high-quality yarn warping.

item |

value |

product |

MACHINE |

material capabilities |

NYLON/POLYESTER MOTHER YARN |

weight (kg) |

13500 |

machine type |

WARPING MACHINE |

video outgoing-inspection |

Provided |

machinery test report |

Provided |

core components |

Engine |

place of origin |

China |

Jiangsu |

|

warranty |

1 Year |

Name |

sectional nylon polyester mother yarn splitting warping machine |

Usage |

1t/day 240D/12F SD |

Warping max speed |

600m/min |

mother yarn tension |

0-500cn |

warping servo moto |

7.5kw |

beam moto |

15kw |

warp beam max speed |

180m/min |

displacement servo |

1.5kw |

Front roller servo |

5.5kw |

Back roller servo |

4.5kw |

EN

EN

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

RO

RO

RU

RU

ES

ES

ID

ID

UK

UK

VI

VI

TH

TH

TR

TR

BN

BN

NE

NE