High Quality Chinese-Made Sectional Splitting and Warping Machine Mother Yarn Division Equipment-Premium Textile Machinery

- Overview

- Inquiry

- Related Products

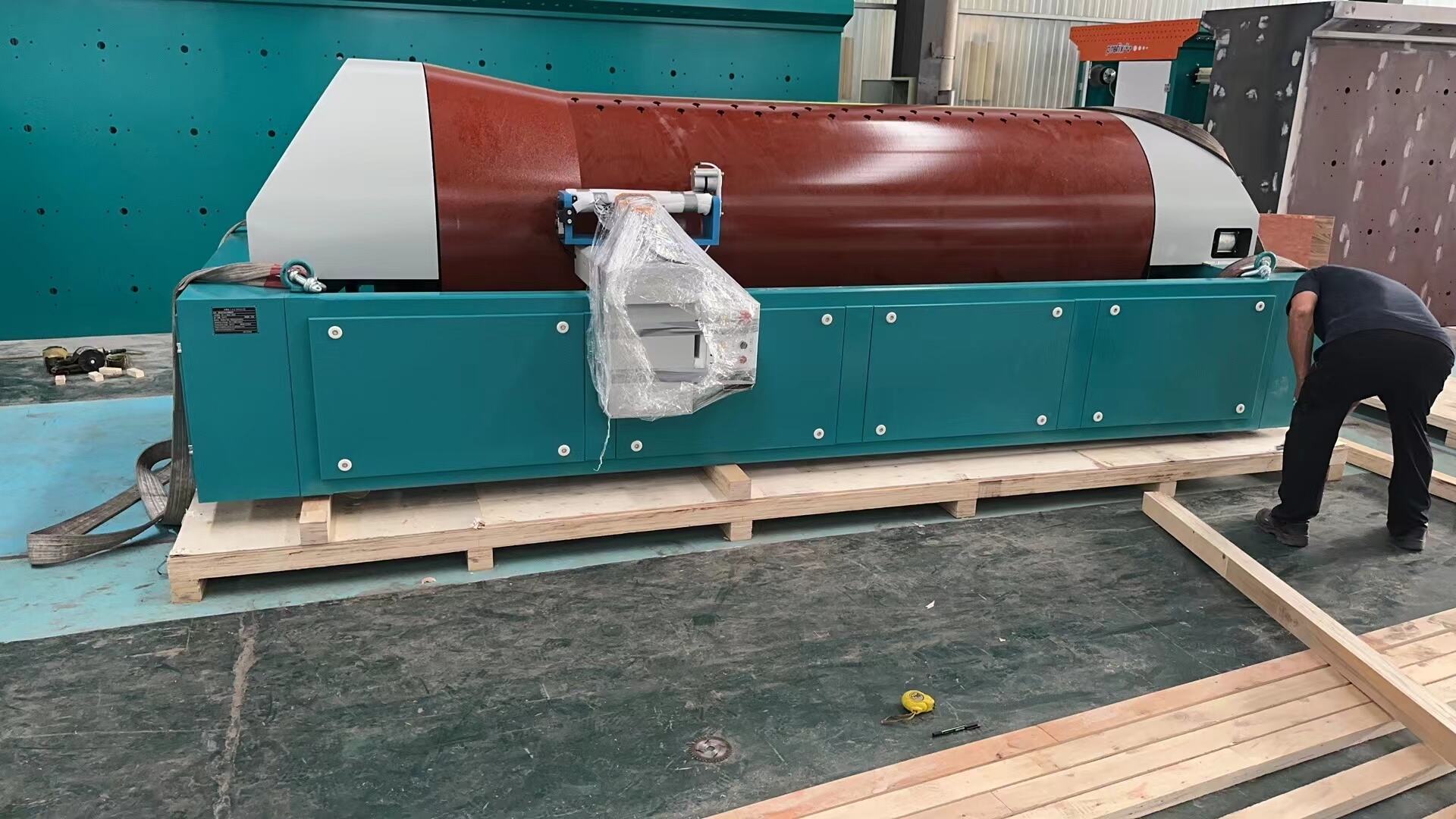

Introducing, the latest tool in textile machinery technology, the High Quality Chinese-Made Sectional Splitting and Warping Machine from the trusted brand profixM. This mother yarn division equipment is built with premium materials and designed with precision to provide exceptional performance and durability.

This advanced machine is specially crafted to divide mother yarn into smaller sections for improved productivity and processing capabilities. Its sectional splitting function enables you to create smaller yarn sections, ensuring ease of handling and storage. Meanwhile, the warping function contributes to a more uniform and consistent result, making it easier to weave and knit different fabrics.

The High Quality Chinese-Made Sectional Splitting and Warping Machine also comes equipped with a user-friendly control system, making it easy to operate and navigate. The machine offers intuitive controls and a comprehensive display for easy monitoring, adjustment, and customization for different processing needs.

With its robust construction, the High Quality Chinese-Made Sectional Splitting, and Warping Machine is capable of performing its functions with reliable and consistent precision, ensuring an uninterrupted workflow. The machine's versatility also allows for different types of yarn to be processed, making it a go-to equipment for your textile production needs.

ProfixM believes in delivering quality products that provide value and efficiency for the textile industry. As such, their High Quality Chinese-Made Sectional Splitting and Warping Machine is built with precision engineering and materials to provide maximum performance and reliability.

Whether you're a textile manufacturer, a fabric retailer, or an artisan, you'll find that this machine is an indispensable tool for enhancing your production capacity and quality. With its innovative features and exceptional capabilities, the High Quality Chinese-Made Sectional Splitting and Warping Machine is a must-have for anyone looking to take their textile production to the next level.

If you're looking for a high-quality mother yarn division equipment that can provide efficient and consistent processing for textiles, the High Quality Chinese-Made Sectional Splitting, and Warping Machine from profixM is a product that you should consider. It is designed to offer superior performance and durability, so your investment in this machine will pay off in streamlined productivity, increased efficiency, and overall profitability. Order yours today

Specification

| item | value | ||

| Applicable Industries | Manufacturing Plant | ||

| Name | YSD-M SECTIONAL MOTHER YARN SPLITTING WARPING MACHINE | ||

| Video outgoing-inspection | Provided | ||

| Machinery Test Report | Provided | ||

| Marketing Type | New Product 2025 | ||

| Warranty of core components | 1 Year | ||

| Place of Origin | China, Jiangsu | ||

| Machine Type | WARPING MACHINE | ||

| Material Capabilities | NYLON/ POLYESTER FDY/ DTY MOTHER YARN | ||

| Condition | New | ||

| Weight (KG) | 17000 | ||

| Yarn Usage | 1t/day 240D/12F SD | ||

| Warping max speed | 600m/min ON 240/12 SD NYLON MOTHER YARN | ||

| warping servo moto | 7.5kw | ||

| beam moto | 15kw | ||

| warp beam max speed | 250m/min | ||

| displacement servo | 1.5kw | ||

| Front roller servo | 5.5kw | ||

| Back roller servo | 4.5kw |

A warp knitting machine is a mechanical device used for weaving warp yarns, which plays an important role in the textile industry

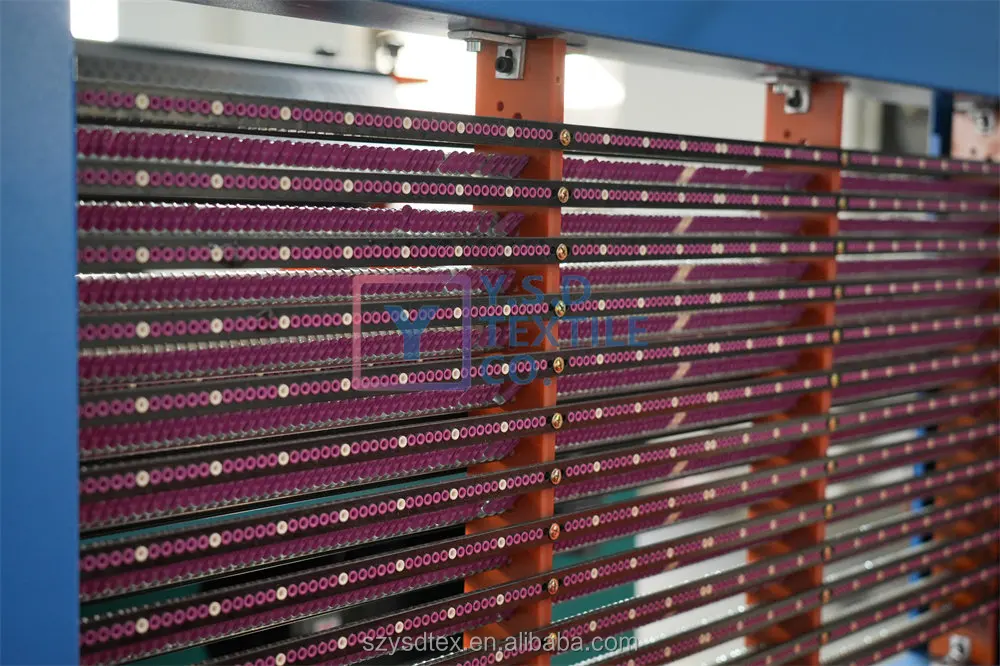

A warp knitting machine is a mechanical device used for weaving warp yarns, which plays an important role in the textile industry Definition and FunctionThe warp knitting machine is mainly used to tear off the raw pulp from a large number of single strands of yarn or blended fabrics, straighten them, and then rewire them on the warp knitting drum to form a "warp knitting". This process is crucial for ensuring the quality of the fabric and the smooth progress of subsequent weaving structureThe warping machine is mainly composed of a frame, a yarn storage rack, warping rollers, tension rollers, correction devices, transmission systems, etc

Definition and FunctionThe warp knitting machine is mainly used to tear off the raw pulp from a large number of single strands of yarn or blended fabrics, straighten them, and then rewire them on the warp knitting drum to form a "warp knitting". This process is crucial for ensuring the quality of the fabric and the smooth progress of subsequent weaving structureThe warping machine is mainly composed of a frame, a yarn storage rack, warping rollers, tension rollers, correction devices, transmission systems, etc

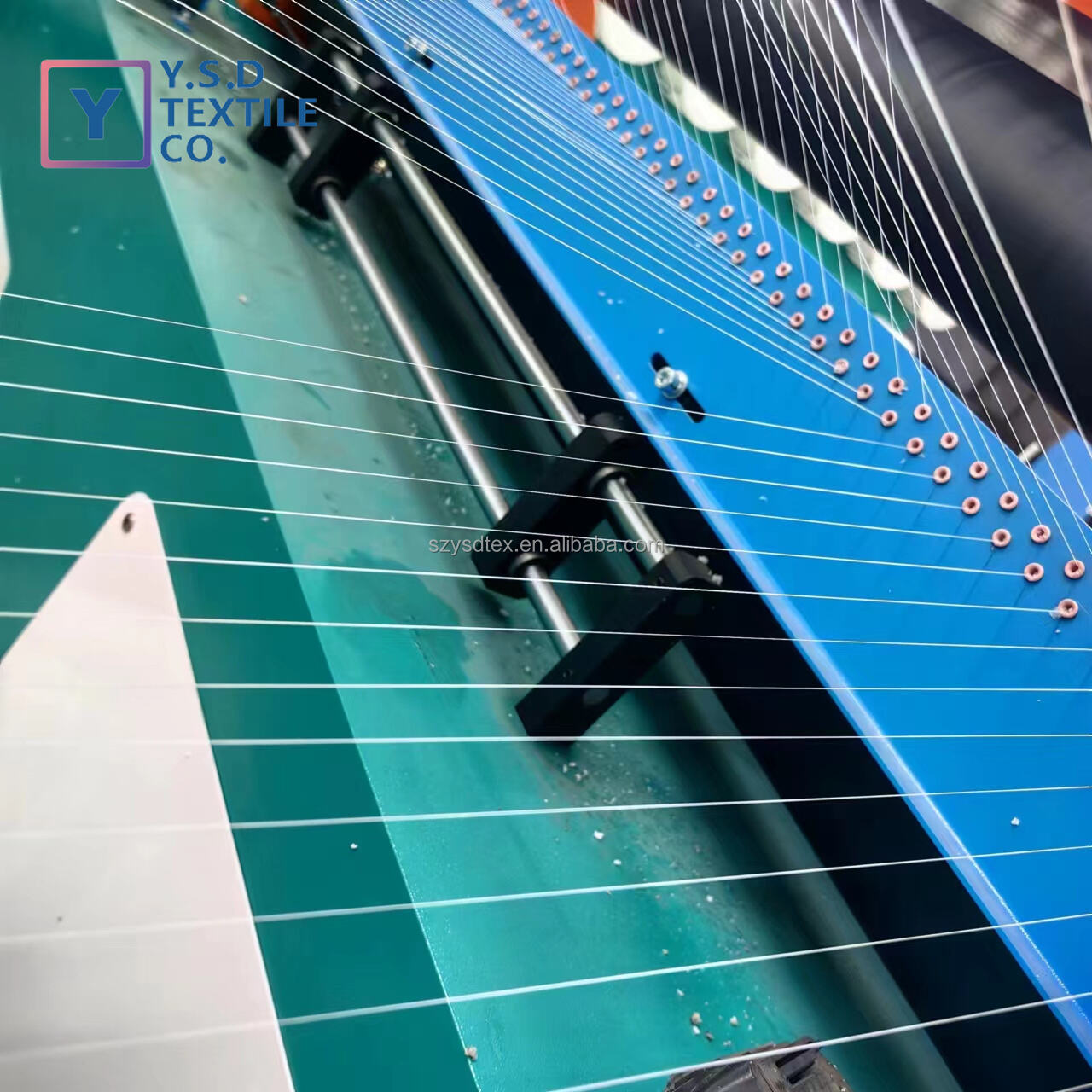

Working principleThe warp yarn is led out from the yarn storage rack, passes through the guide roller and tension roller, and enters the warping roller; The warp roller shapes the warp yarn into sheets according to a certain length and width; The correction device ensures that the warp yarn pieces are arranged neatly; Finally, the warp yarn passes through the transmission system to complete the warping processAdvantages and Applications

Working principleThe warp yarn is led out from the yarn storage rack, passes through the guide roller and tension roller, and enters the warping roller; The warp roller shapes the warp yarn into sheets according to a certain length and width; The correction device ensures that the warp yarn pieces are arranged neatly; Finally, the warp yarn passes through the transmission system to complete the warping processAdvantages and Applications

1) The warping machine has the characteristics of high efficiency, stability, and reliability, which can greatly improve the production efficiency of the textile industry.

2) Its high precision and consistency ensure the quality of the fabric, making it more neat and uniform.

3) The warping machine is widely used in the textile industry and is one of the very important production equipment in textile factories

About Us About Us

About Us

Suzhou YSD Textile Co., Ltd. is located in Pingwang Town, Yangtze River Delta, covers an area of 20000 square meters, mainly produces top grade high-speed mother yarn sectional split warping machine, mother yarn splitting machine, all kinds of women's fabrics, subordinate Wujiang Telong Chemical Fiber Co., Ltd. is located in Zhenze Town, covers an area of 20000 square meters, production of nylon/ polyester monofilament yarn, mother yarn, organza (textured) yarn, feather yarn 8000 tons each year, our third phases of spinning building has started construction, after the completion of the annual output can be above 20000 tons. We are based on the perspective of customers, to help you solve problems, grow together, mutual benefit and win-win

Our loyal customers have already been enjoying the products which were created by using Yunshunda high technology machine. We believe that our machine will be the right choice of your warping production

Our loyal customers have already been enjoying the products which were created by using Yunshunda high technology machine. We believe that our machine will be the right choice of your warping production

Certifications

Certifications

Through the certification we allow customers to our products with more confidence but the most important thing is the quality of our products Exhibition

Exhibition

FAQQ:Are you manufacturer

FAQQ:Are you manufacturer

A:Yes, We are manufacturer

Q:How to place machines order

A:Please send us your purchase order by email, whatsapp or wechat. We need to know the following information for your order:

(1) Your products width and thickness - webbing, tapes, lace width and thickness

(2) Price Item, Destination Port, Delivery time required

(3) Shipping information: Company Name, Address, Phone Number, Destination Seaport/Airport

Q:What are the payment terms

A:For orders, we can accept T/T, L/C at sight

Q:How many years of producing these machine

A: We produced these machine for more than 15 years

EN

EN

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

RO

RO

RU

RU

ES

ES

ID

ID

UK

UK

VI

VI

TH

TH

TR

TR

BN

BN

NE

NE