High Quality Textile Parts Warping Machine New Condition Mother Yarn Machinery Core Motor Component Manufacturing Plant

- Overview

- Inquiry

- Related Products

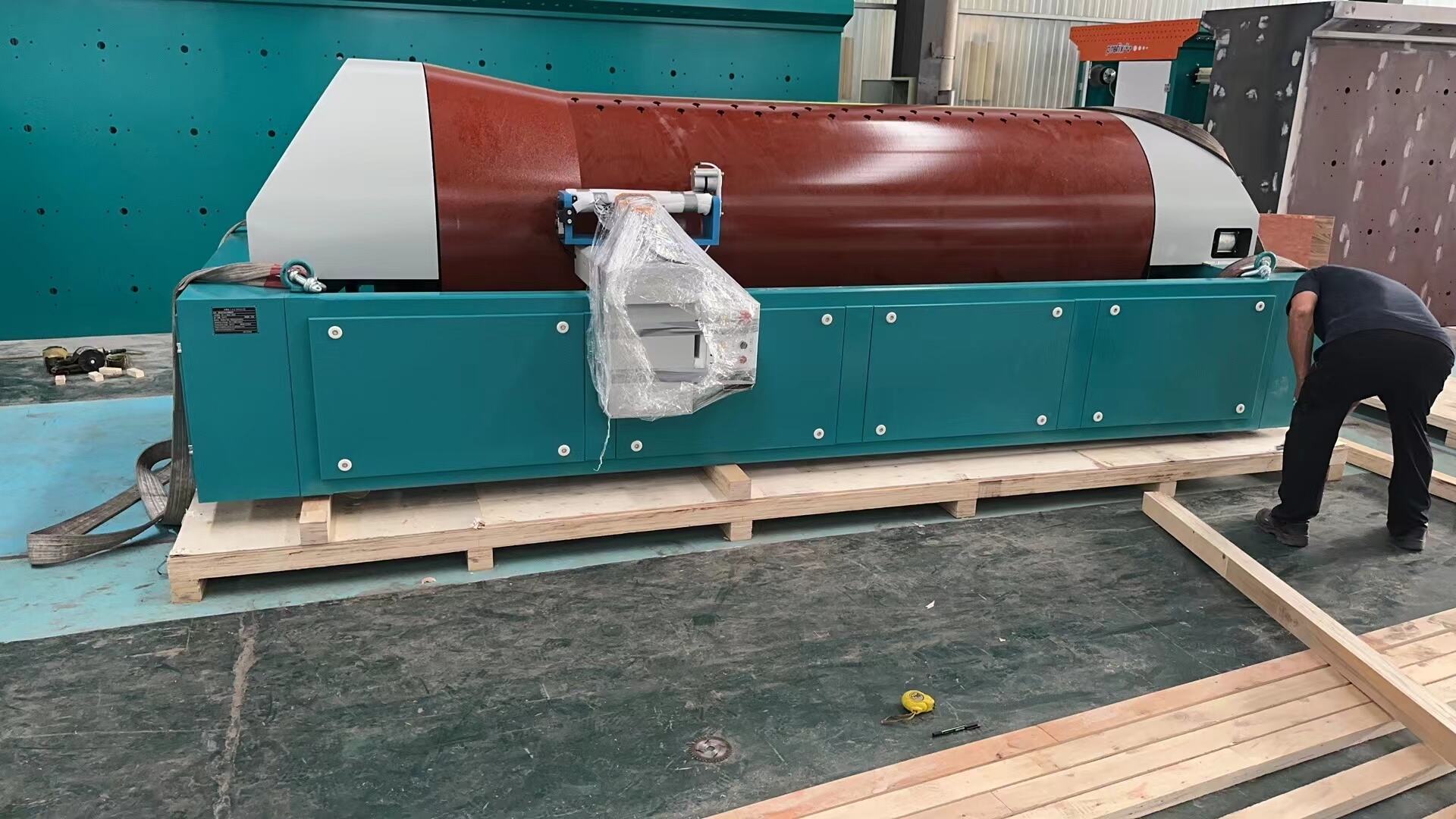

The profixM’s High Quality Textile Parts Warping Machine is a top-of-the-line product that is designed to make yarn production easier and more efficient. Made from durable materials, this machine is built to withstand the demands of the modern manufacturing plant and can handle a range of thread counts to give you the ultimate precision and consistency.

At the heart of the profixM’s Warping Machine is the new condition Mother Yarn Machinery Core Motor Component, which plays a crucial role in how the machine performs. The machinery core motor component is the most reliable and efficient means of powering the warping machine, and it guarantees steady, reliable, and consistent outputs throughout the production process.

Manufactured by a renowned Textile Parts and Machinery Core Motor Component Manufacturing Plant, the profixM’s High Quality Textile Parts Warping Machine is an assurance of quality, excellence, and value for your money. You can rest easy, knowing that you are getting the best product, from a trusted brand that has been delivering dependable textile parts and machinery components across the industry for years.

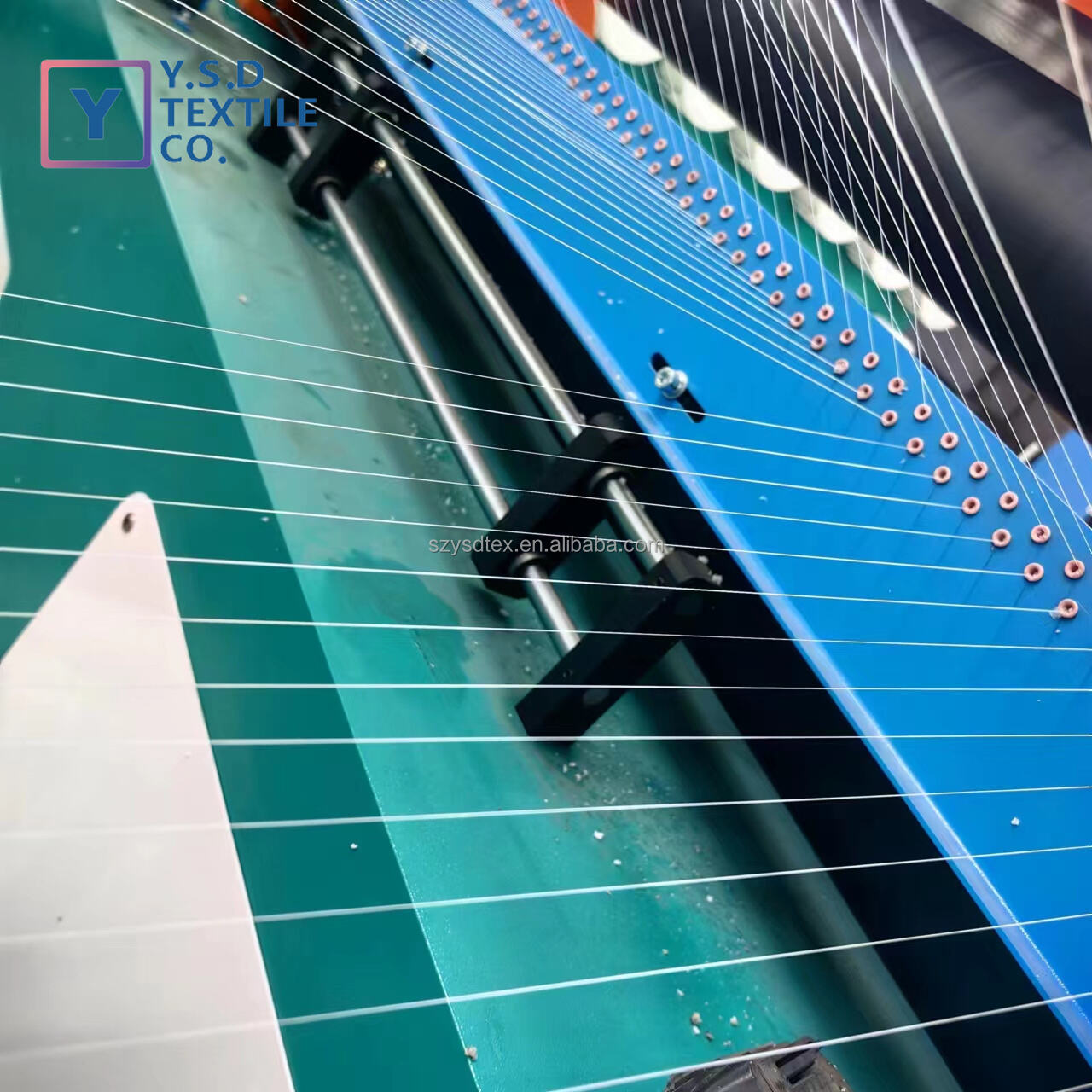

The warping process is a critical part of textile production, and it requires a great deal of precision. With the profixM’s High Quality Textile Parts Warping Machine, you will enjoy greater accuracy and efficiency in your weaving tasks, and you can produce more yarn with fewer errors. The machine is designed to calculate the warp length and tension, as well as optimizing size segments to give you the best possible results.

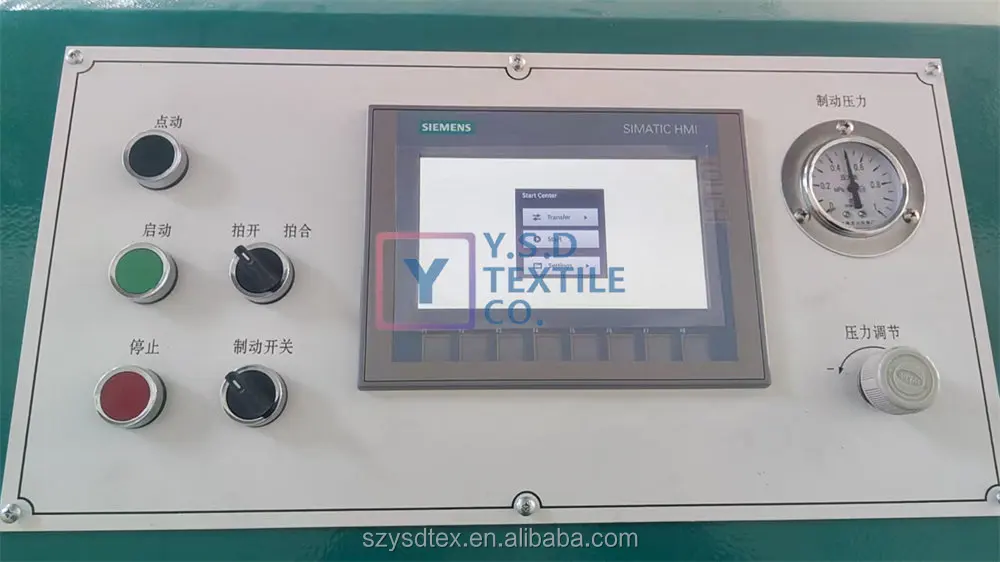

The profixM’s High Quality Textile Parts Warping Machine is also easy to operate and maintain, with user-friendly controls and a comprehensive range of safety features. Cleaning and maintaining the machine is a breeze, ensuring that there are no contaminants and that the machine is always operating at optimal performance.

The profixM’s High Quality Textile Parts Warping Machine is the perfect addition to any textile production line that wants greater efficiency, accuracy, and consistency in their yarn production. With the latest technology and top-of-the-line machinery core motor component, it is an investment that guarantees a return on investment and significant savings in your production costs. Trust the profixM brand for quality, durability, and reliable textile parts production

item |

value |

product |

MACHINE |

material capabilities |

NYLON/POLYESTER MOTHER YARN |

weight (kg) |

17000 |

machine type |

WARPING MACHINE |

Video outgoing-inspection |

Provided |

machinery test report |

Provided |

core components |

Engine |

Place of origin |

China |

Jiangsu |

|

warranty |

1 Year |

Name |

NYLON POLYAMIDE POLYESTER MOTHER YARN WARPING MACHINE |

Usage |

1t/day 240D/12F SD |

Warping max speed |

600m/min |

mother yarn tension |

0-500cn |

warping servo moto |

7.5kw |

beam moto |

15kw |

warp beam max speed |

250m/min |

displacement servo |

1.5kw |

Front roller servo |

5.5kw |

Back roller servo |

4.5kw |

1) The warping machine has the characteristics of high efficiency, stability, and reliability, which can greatly improve the production efficiency of the textile industry.

2) Its high precision and consistency ensure the quality of the fabric, making it more neat and uniform.

3) The warping machine is widely used in the textile industry and is one of the very important production equipment in textile factories

Q:How to place machines order

A:Please send us your purchase order by email, whatsapp or wechat. We need to know the following information for your order:

(1) Your products width and thickness(webbing, tapes, lace width and thickness)

(2) Price Item, Destination Port, Delivery time required

(3) Shipping information: Company Name, Address, Phone Number, Destination Seaport/Airport

Q:What are the payment terms

A:For orders, we can accept T/T, L/C at sight

Q:How many years of producing these machine

---We produced these machine for more than 15 years

EN

EN

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

RO

RO

RU

RU

ES

ES

ID

ID

UK

UK

VI

VI

TH

TH

TR

TR

BN

BN

NE

NE