High-Speed Automatic Sectional Split Mother Yarn Warping Machine New Condition Cotton Textile Industries Shoelace

- Overview

- Inquiry

- Related Products

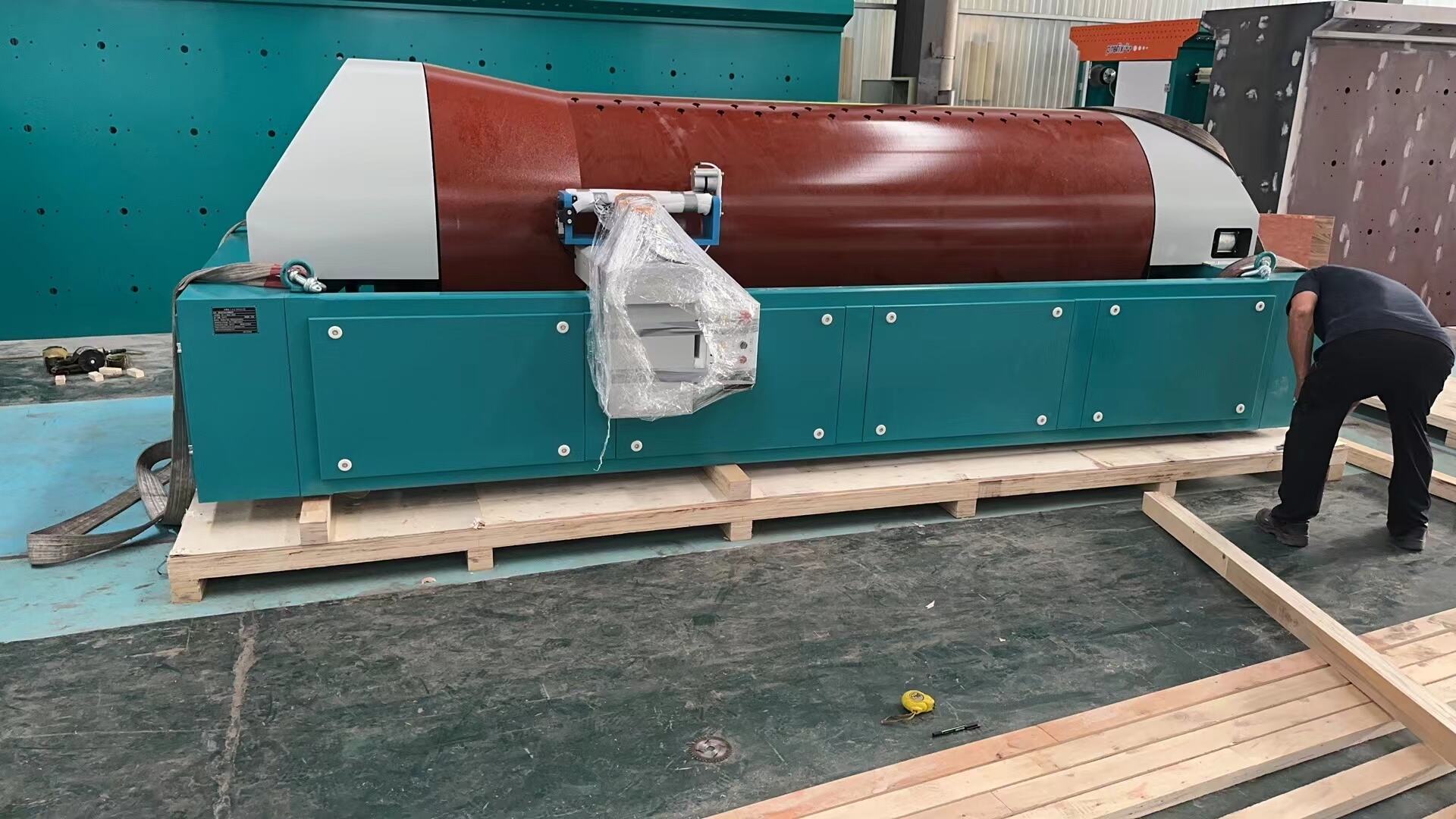

Introducing, the ProfixM’s High-Speed Automatic Sectional Split Mother Yarn Warping Machine – the new must-have equipment for cotton textile industries and shoelace manufacturers

This top-of-the-line machine is designed to provide fast and efficient warping of mother yarn. Unlike other machines that require manual intervention, this one is fully automated, making it easy to use for even the most inexperienced operator.

The ProfixM’s High-Speed Automatic Sectional Split Mother Yarn Warping Machine boasts a modern design that is built to last. With sturdy materials used for its construction, the machine is durable and can withstand long hours of use without breaking down.

One of the best things about this machine is its fast warping ability. It has a rapid warping speed that can significantly increase production capacity, making it ideal for high-volume projects. It also comes with an automatic warping stop function, ensuring that the machine stops when the set yardage is reached.

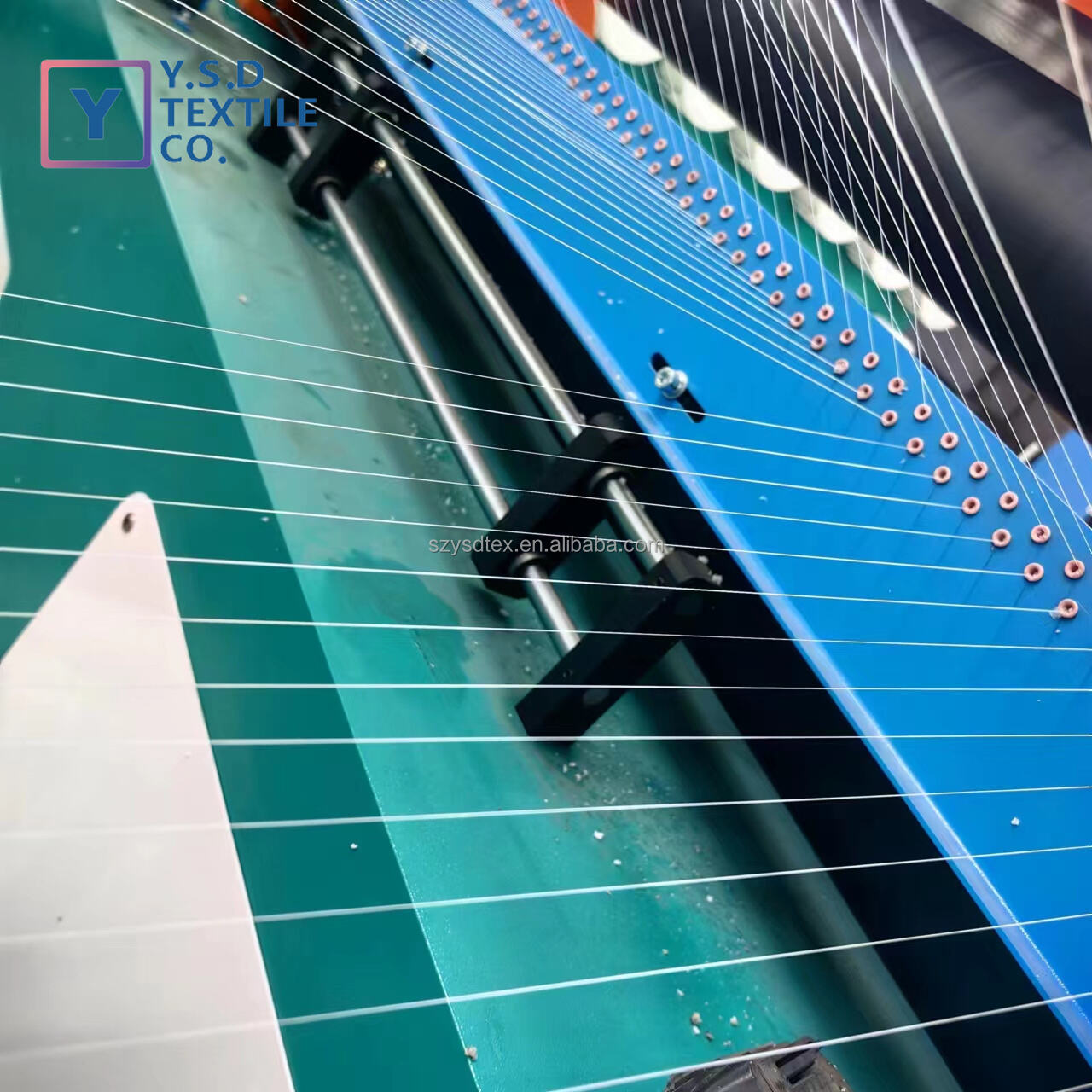

The machine's sectional split mother yarn warping feature is particularly helpful for shoelace manufacturers. This allows you to create different ribbon patterns, making it easier to produce various shoelace styles and designs. The machine's programmable controller lets you input your specifications and desired settings, making the process even more comfortable and convenient.

Another great feature of the ProfixM’s High-Speed Automatic Sectional Split Mother Yarn Warping Machine is its ability to maintain yarn tension consistently throughout the warping process. This ensures that the yarn doesn't stretch or break, resulting in smooth and stable production output.

Cleaning and maintenance are also relatively comfortable with this machine. Its user-friendly interface makes it easy to dismantle and replace parts, saving you time and money on repairs.

The ProfixM’s High-Speed Automatic Sectional Split Mother Yarn Warping Machine is an excellent investment for any cotton textile industry or shoelace manufacturer looking to increase productivity and enhance the quality of their output. With its efficient warping process, sectional split mother yarn feature, and user-friendly interface, it's the perfect machine to help grow your business

item |

value |

Applicable Industries |

Manufacturing Plant |

Weight (KG) |

1500 |

Showroom Location |

None |

Video outgoing-inspection |

Provided |

Machinery Test Report |

Provided |

Marketing Type |

New Product 2024 |

Warranty of core components |

1 Year |

Core Components |

Engine |

Place of Origin |

China |

Jiangsu |

|

Warranty |

1 Year |

Machine Type |

WARPING MACHINE |

Product |

MACHINE |

Material Capabilities |

NYLON/POLYESTER MOTHER YARN |

Condition |

New |

Name |

Sectional splitting Warping Machine Spara Parts steel buckle |

Usage |

On warping/knitting/ warp knitting machine |

Warping max speed |

650m/min |

mother yarn tension |

0-500cn |

warping servo moto |

7.5kw |

beam moto |

15kw |

warp beam max speed |

250m/min |

displacement servo |

1.5kw |

Front roller servo |

5.5kw |

Back roller servo |

4.5kw |

1) The warping machine has the characteristics of high efficiency, stability, and reliability, which can greatly improve the production efficiency of the textile industry.

2) Its high precision and consistency ensure the quality of the fabric, making it more neat and uniform.

3) The warping machine is widely used in the textile industry and is one of the very important production equipment in textile factories

Q:How to place machines order

A:Please send us your purchase order by email, whatsapp or wechat. We need to know the following information for your order:

(1) Your products width and thickness(webbing, tapes, lace width and thickness)

(2) Price Item, Destination Port, Delivery time required

(3) Shipping information: Company Name, Address, Phone Number, Destination Seaport/Airport

Q:What are the payment terms

A:For orders, we can accept T/T, L/C at sight

Q:How many years of producing these machine

---We produced these machine for more than 15 years

EN

EN

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

RO

RO

RU

RU

ES

ES

ID

ID

UK

UK

VI

VI

TH

TH

TR

TR

BN

BN

NE

NE