High-Speed Automatic Sectional Split Warping Beaming Machine China Wholesale Customized Yarn New Condition Motor

- Overview

- Inquiry

- Related Products

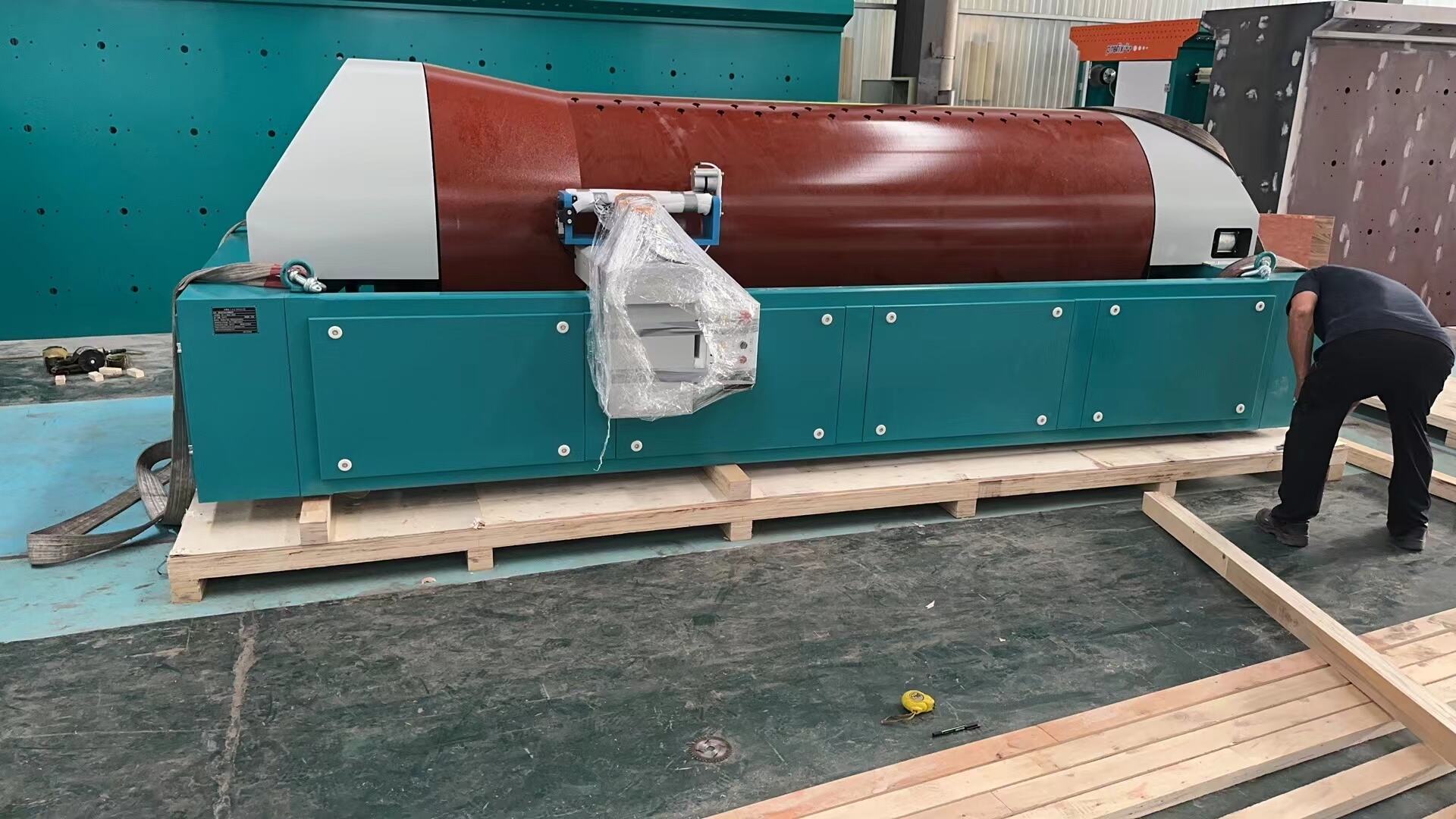

Introducing, the proficient and innovative high-speed automatic sectional split warping beaming machine by ProfixM, the leading manufacturer of high-quality textile manufacturing machinery. This cutting-edge product is designed to cater to the needs of textile manufacturers who are looking for high-performance and efficient machines to streamline their manufacturing process.

This machine is crafted using the latest technology that guarantees high-precision, accuracy, and optimum performance. The warping and beaming machine is fully automated, reducing the need for manual interventions, saving time, and increasing productivity significantly. It's a dependable tool for textile manufacturers of varying production levels.

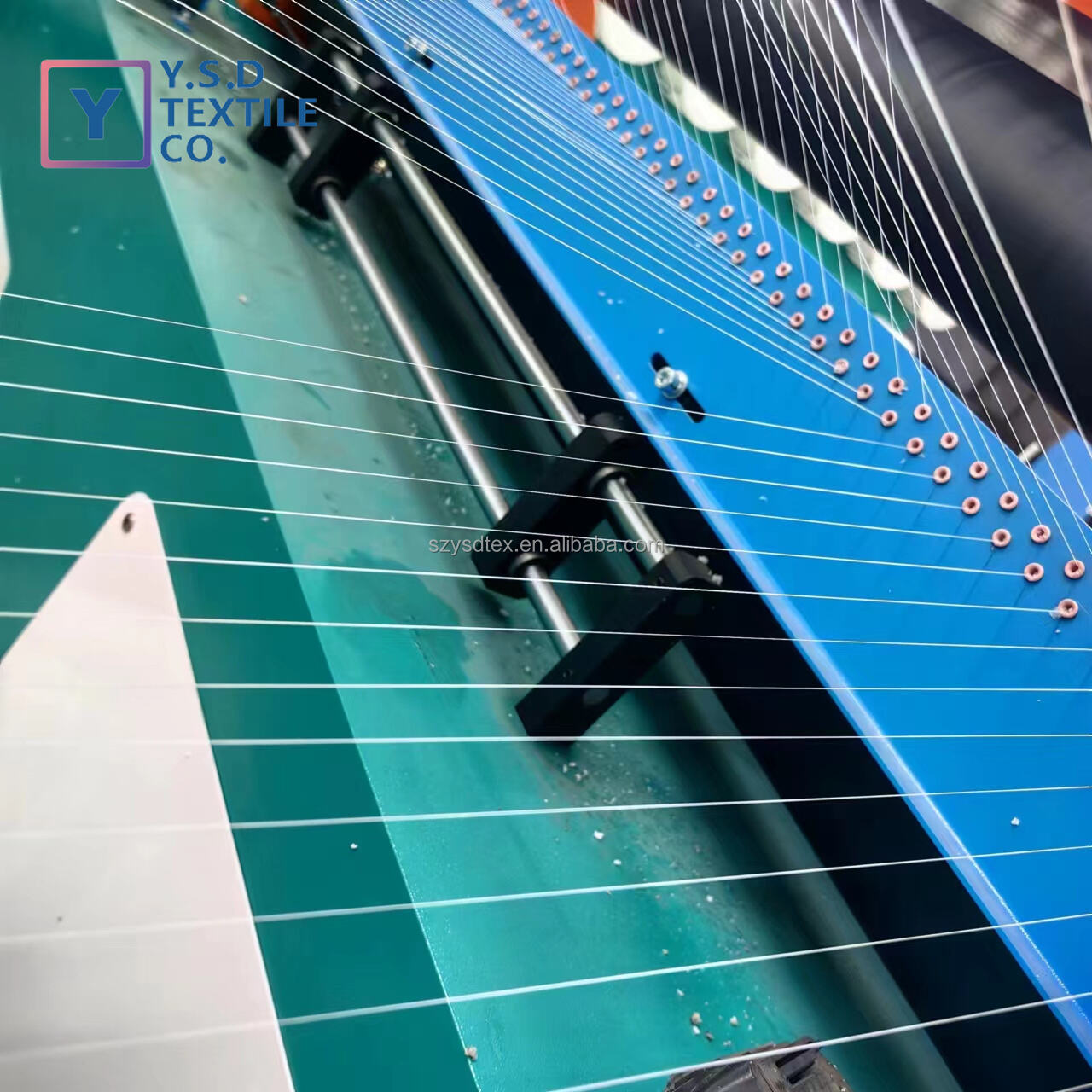

The machine has multiple functions that make it a top choice for customizing yarn and producing high-quality fabrics. With its sectional split structure design, the machine can maintain consistent tension throughout the process, ensuring that the final product is of impeccable quality. It's fitted with a powerful motor that facilitates the production of yarn at high speeds, contributing to higher productivity levels.

ProfixM understands that clients have varying needs when it comes to textile manufacturing machines. The brand offers customized options for clients who require machine functionality tailored to their business needs. Clients can specify the dimensions, color, and various features they need to ensure their textile manufacturing process is streamlined.

The machine is easy to operate, maintain, and service. The engineers at ProfixM have ensured that the machine is user-friendly, thus reducing the risk of errors and damages. The machine also has an automatic stop function that halts the machine when it's impending a problem that could interrupt the production process.

With ProfixM's high-speed automatic sectional split warping beaming machine, textile manufacturers can enhance their production, reduce labor costs, and enhance quality. The machine guarantees fast production speeds, consistent quality, and efficiency, making it a great asset for any textile manufacturing company aiming to remain competitive in the market.

If you are looking for a reliable, efficient, and robust machine for textiles manufacturing, ProfixM's high-speed automatic sectional split warping beaming machine is a great choice. It's a state-of-the-art machine that guarantees maximum productivity, high-quality fabrics, customized options, and user-friendliness. ProfixM is a trusted brand that has been delivering top-quality textile machines for years, and their warping and beaming machine is not an exception. Get in touch with them today to get a quote and place your order

item |

value |

||||||

Applicable Industries |

Manufacturing Plant |

||||||

Name |

SECTIONAL MOTHER YARN SPLITTING WARPING MACHINE |

||||||

Video outgoing-inspection |

Provided |

||||||

Machinery Test Report |

Provided |

||||||

Marketing Type |

New Product 2025 |

||||||

Warranty of core components |

1 Year |

||||||

Place of Origin |

China, Jiangsu |

||||||

Machine Type |

WARPING MACHINE |

||||||

Material Capabilities |

NYLON/ POLYESTER FDY/ DTY MOTHER YARN |

||||||

Condition |

New |

||||||

Weight (KG) |

17000 |

||||||

Yarn Usage |

1t/day 240D/12F SD |

||||||

Warping max speed |

600m/min ON 240/12 SD NYLON MOTHER YARN |

||||||

warping servo moto |

7.5kw |

||||||

beam moto |

15kw |

||||||

warp beam max speed |

180m/min |

||||||

displacement servo |

1.5kw |

||||||

Front roller servo |

5.5kw |

||||||

Back roller servo |

4.5kw |

||||||

1) The warping machine has the characteristics of high efficiency, stability, and reliability, which can greatly improve the production efficiency of the textile industry.

2) Its high precision and consistency ensure the quality of the fabric, making it more neat and uniform.

3) The warping machine is widely used in the textile industry and is one of the very important production equipment in textile factories

Q:How to place machines order

A:Please send us your purchase order by email, whatsapp or wechat. We need to know the following information for your order:

(1) Your products width and thickness(webbing, tapes, lace width and thickness)

(2) Price Item, Destination Port, Delivery time required

(3) Shipping information: Company Name, Address, Phone Number, Destination Seaport/Airport

Q:What are the payment terms

A:For orders, we can accept T/T, L/C at sight

Q:How many years of producing these machine

---We produced these machine for more than 15 years

EN

EN

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

RO

RO

RU

RU

ES

ES

ID

ID

UK

UK

VI

VI

TH

TH

TR

TR

BN

BN

NE

NE