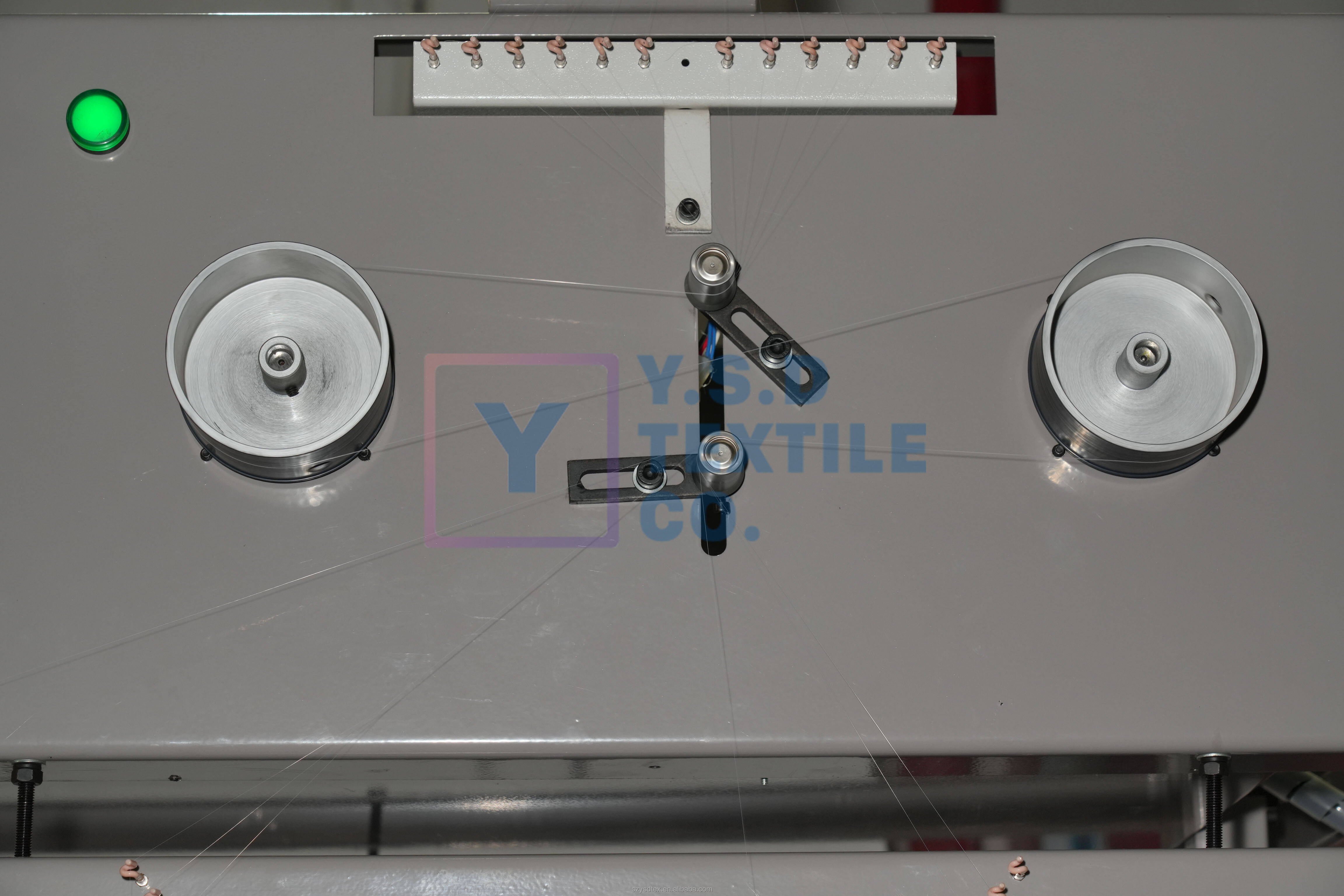

Introducing, the all-new ProfixM’s high-speed nylon and polyester mother yarn splitting machine that is perfect for textile manufacturers. This top-of-the-line machinery is designed to split mother yarn into individual filaments quickly and efficiently on paper tubes for further processing. With this machine, you can transform your textiles into high-quality woven or knitted fabrics in no time!

The ProfixM’s machine is built to last with sturdy and reliable construction, ensuring that your textile manufacturing process is as seamless as possible. The high-speed motor brings you the added benefit of improving your production time, as it can create up to hundreds of individual filaments in just a few minutes. The machine is also able to withstand high-pressure conditions and heavy usage, making it ideal for textile manufacturing companies that need durable and high-performing machinery.

One of the most significant features of the ProfixM’s machine is its versatility. It is capable of working with a wide range of textiles such as nylon and polyester fibers, which are some of the most commonly used materials in the industry. The machine is designed to work with various types of mother yarn and can effectively split them into individual filaments, which can then be spun into yarn or used as filling material.

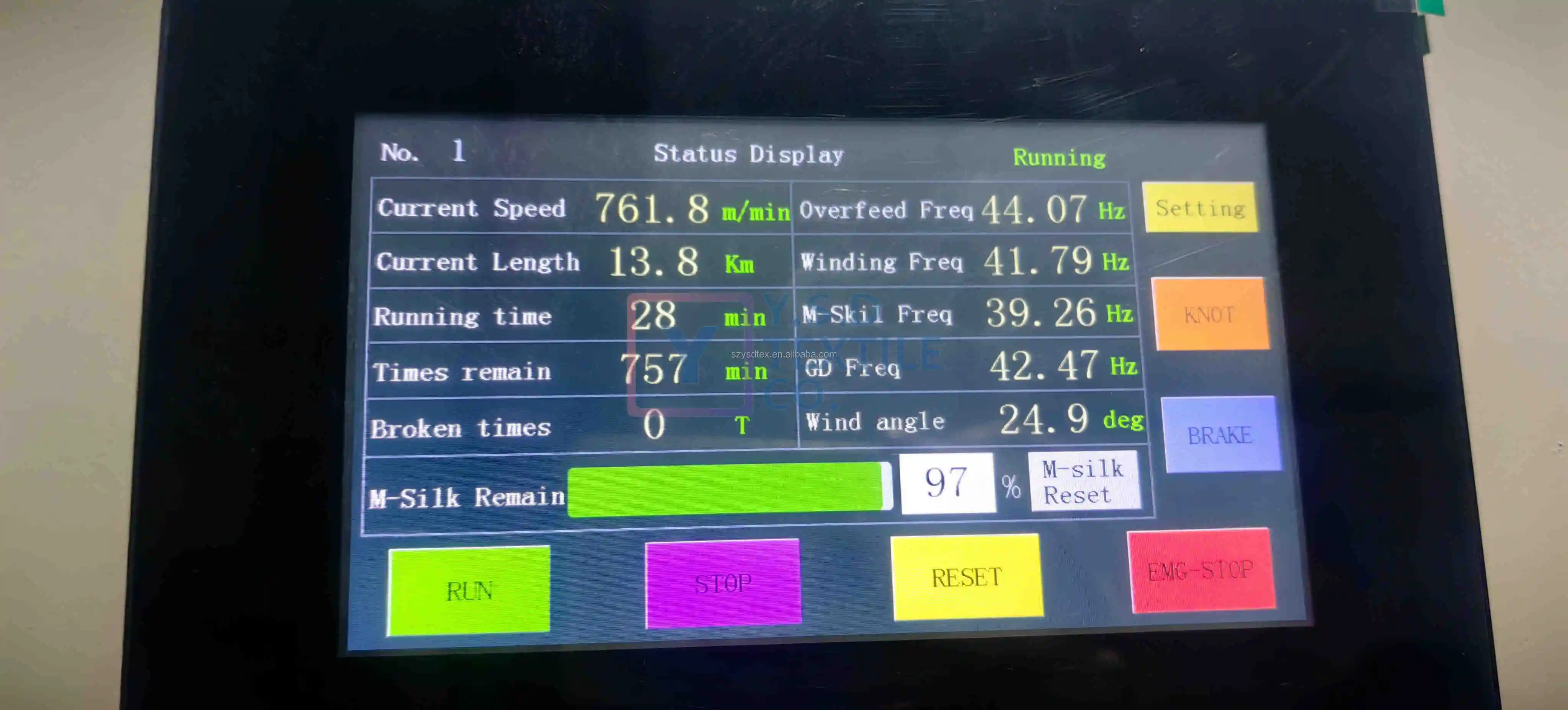

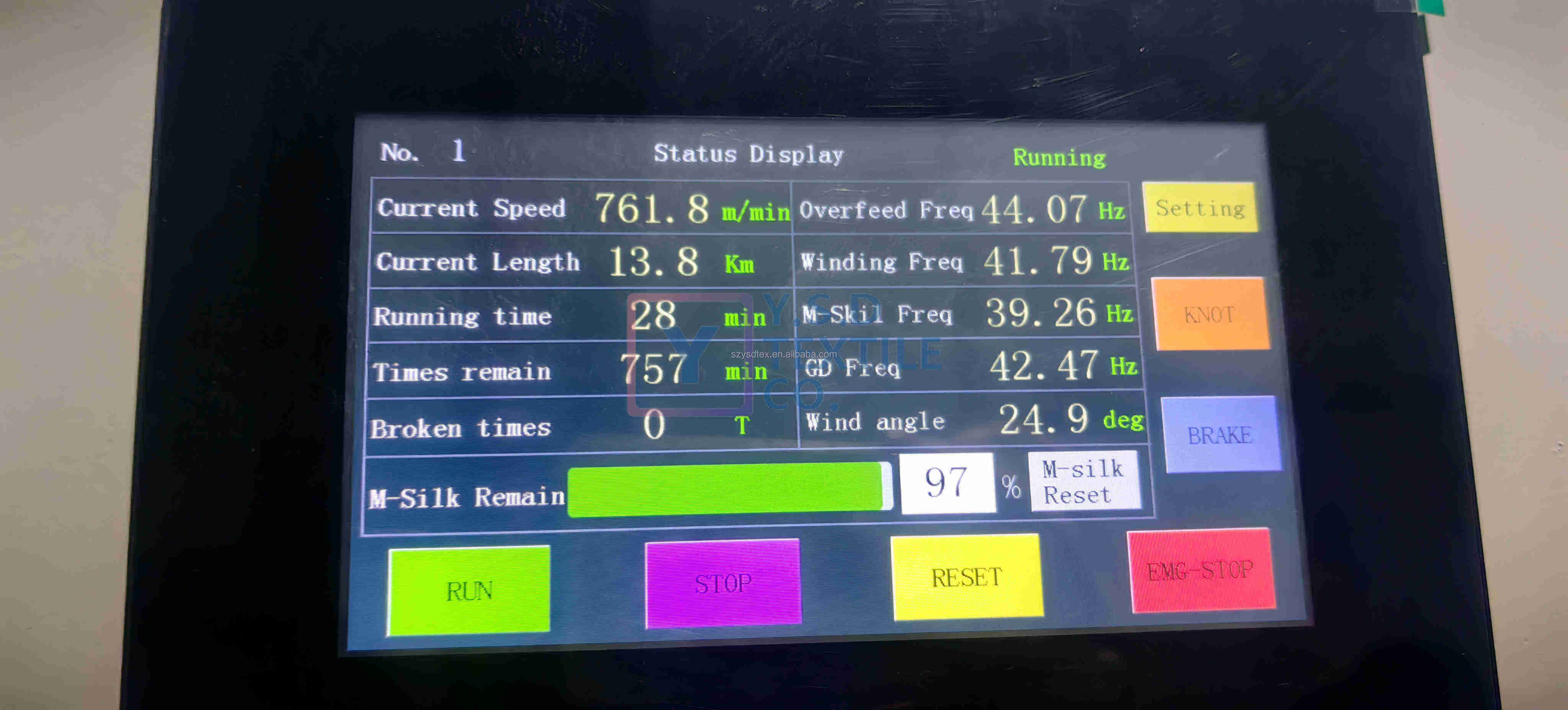

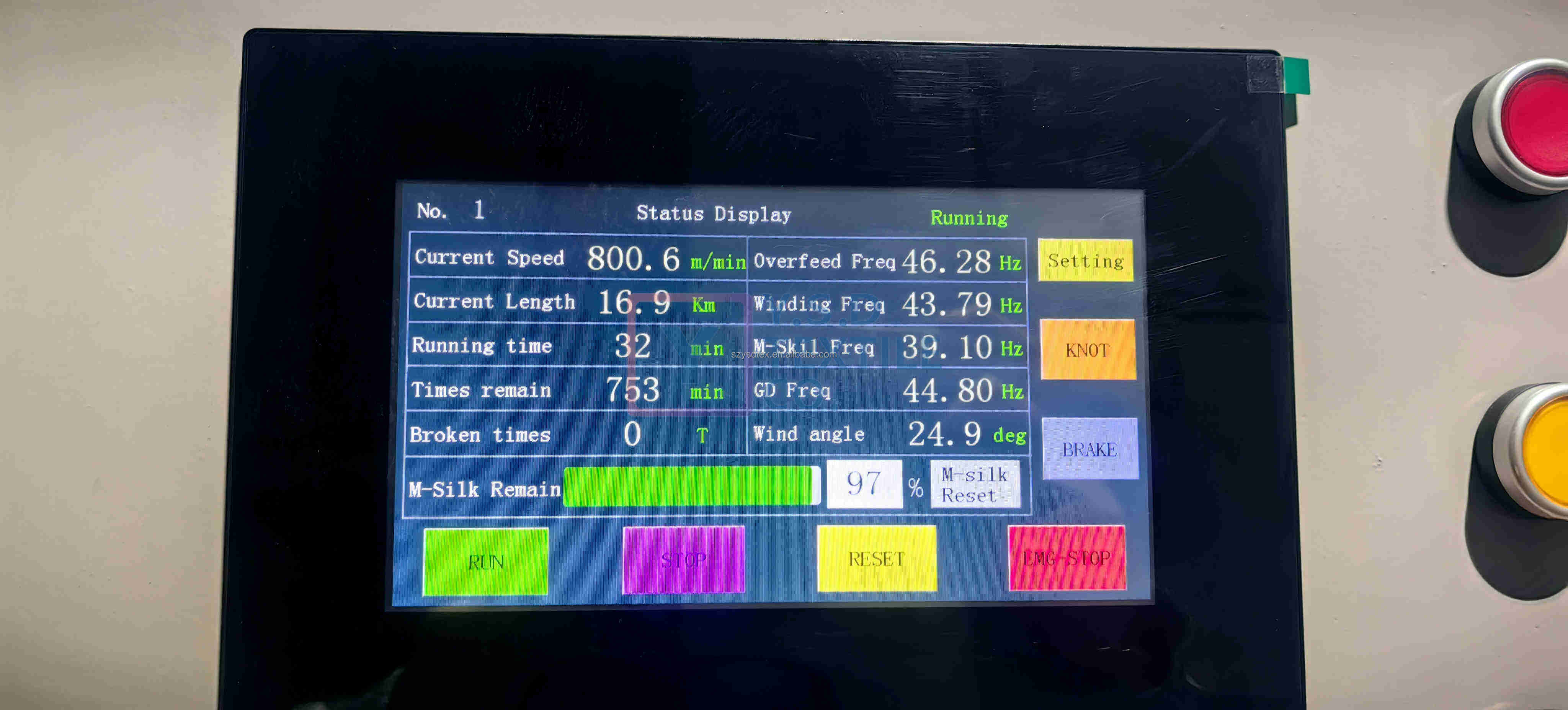

Another benefit of the ProfixM’s nylon and polyester mother yarn splitting machine is its user-friendly interface. The machine is easy to operate, with simple controls that even novice operators can grasp quickly. It comes with detailed instructions that allow for easy setup and use, ensuring that you can get started on your textile manufacturing process right away.

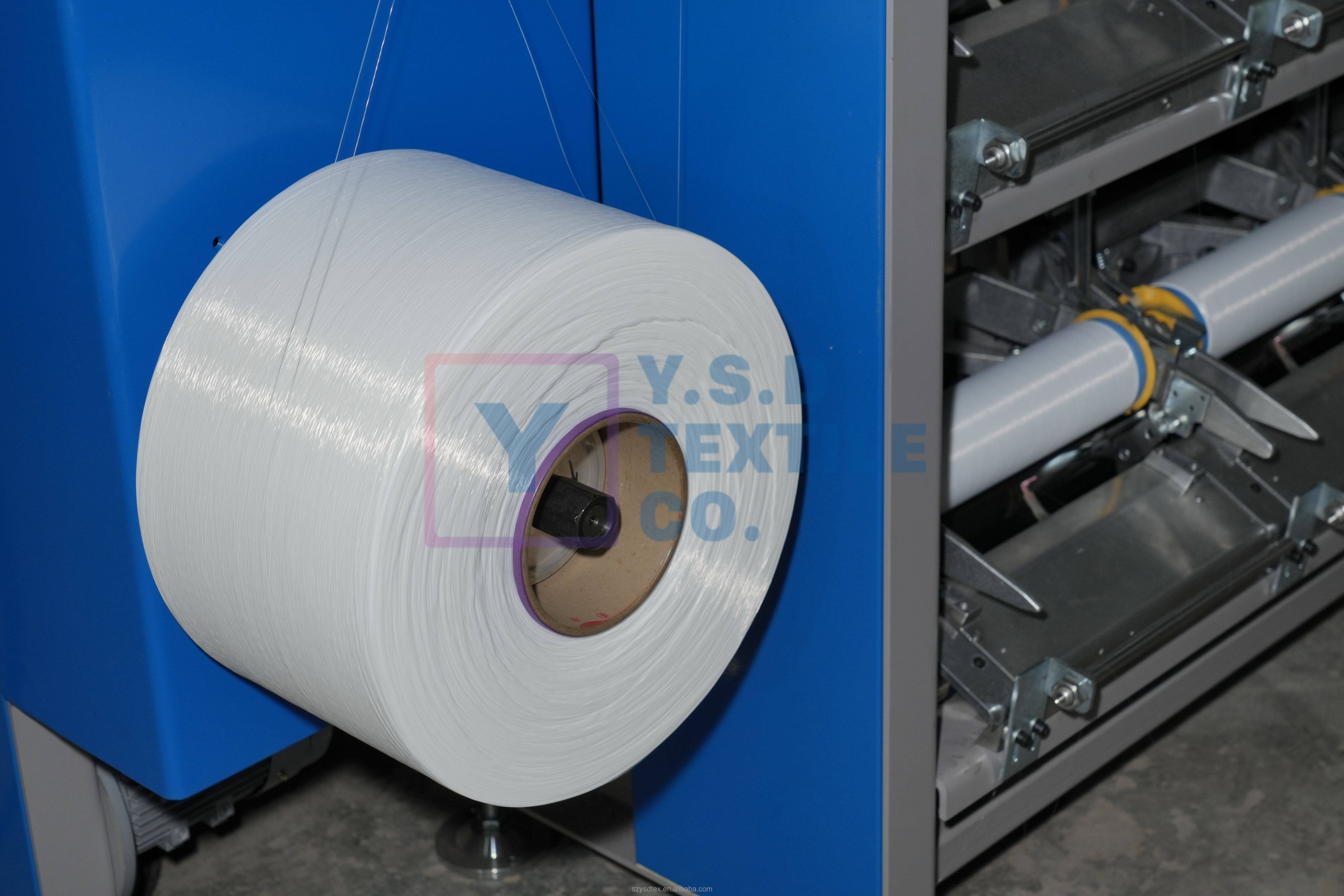

The machine also comes equipped with a rolling system that ensures that the individual filaments are wound tightly and evenly onto the paper tube. This ensures that the filaments are not tangled or bunched up, making them easier to handle and process further. The system is adjustable, allowing you to customize the winding process to your unique needs.

The ProfixM’s high-speed nylon and polyester mother yarn splitting machine is the perfect addition to any textile manufacturer's machinery fleet. Its durable construction, high-speed motor, and versatile design make it ideal for splitting mother yarn and transforming it into high-quality woven or knitted fabrics. With this machine, you can produce textiles faster, more efficiently, and with greater accuracy than ever before. Don't hesitate, and get yourself a ProfixM’s mother yarn splitting machine today

item |

value |

product |

Machine |

material capabilities |

Nylon and polyester mono yarn |

Weight (kg) |

600 |

machine type |

Mother yarn splitting machine |

Video outgoing-inspection |

Provided |

machinery test report |

Provided |

core components |

Engine |

place of origin |

China |

|

Jiangsu |

warranty |

1 Year |

Name |

Mother yarn splitting machine |

Winding coil skeleton |

95-130x230mm |

Splitting tension |

0.6g/d- 1.0g/d |

Winding |

120*2300mm |

splitting speed |

200D/10F can reach 800/min |

Forming device |

100mm-460mm |

Spindle motor |

1kw |

Wire feed motor |

0.24kw |

Forming motor |

0.02kw |

Spitting motor |

0.02kw |

Mother yarn splitting machine rolling on paper bobbin

1. stable tension on each Splitted bobbin from beginning to end

2. use normal DTY paper bobbin, low production cost and easy found

3. no weight limit on mother yarn size, 12kg -- 24kg can run

4. running speed 800-900 m/min

5. friction drum control each spindle, no need each Splitted bobbin same size, according to your require decide each bobbin size during splitting

spindles |

height |

length |

width |

24 |

1900mm |

2000mm |

1000mm |

1. Spindles

One side 12 spindles, two sides total 24 spindles (separate control)

2. Paper bobbin size

Length 290mm, outsize 78mm, inner size 67mm and 56mm,

3. Stable tension

Friction drum keep each bobbin same tension

4. Export package

5 sets in 1*20GP11 sets in 1*40HQ

5. Split mother yarn

Nylon and polyester mono yarn with 10D-70D, within 12F

6. Easy control system

Delta motors, English control system

Suzhou YSD Textile Co., Ltd. is located in Pingwang Town, Yangtze River Delta, covers an area of 20000 square meters, mainly produces top grade high-speed mother yarn sectional split warping machine, mother yarn splitting machine, all kinds of women's fabrics, Wujiang Telong Chemical Fiber Co., Ltd. is located in Zhenze Town, covers an area of 20000 square meters, production of nylon/ polyester monofilament yarn, mother yarn, organza (textured) yarn, feather yarn 8000 tons each year, our third phases of spinning building has started construction, after the completion of the annual output can be above 20000 tons. We are based on the perspective of customers, to help you solve problems, grow together, mutual benefit and win-win

1. How about production timeEach group of machine production time 40-50 days, 50 sets each group

2. How about payment term

T/T 3/7 before delivery, LC at sight

3. How about production quantity

Each 24 hours run 60KG of Nylon 240/12 mother yarn at each machine (two sides)

4. How about speed at machine

Normally run 800-1000m/min

5. How about electric match

Use Delta motor, running power about 2kw, start power 1.5kw

Welcome contact Rosie by whatsapp/ wechat/ phone: +86 152 6197 6205

EN

EN

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

RO

RO

RU

RU

ES

ES

ID

ID

UK

UK

VI

VI

TH

TH

TR

TR

BN

BN

NE

NE