Hot Sale Advanced Fully Automatic Mother Yarn Warping Splitting Machine High Speed Auto Dividing with New Core Motor Component

- Overview

- Inquiry

- Related Products

ProfixM

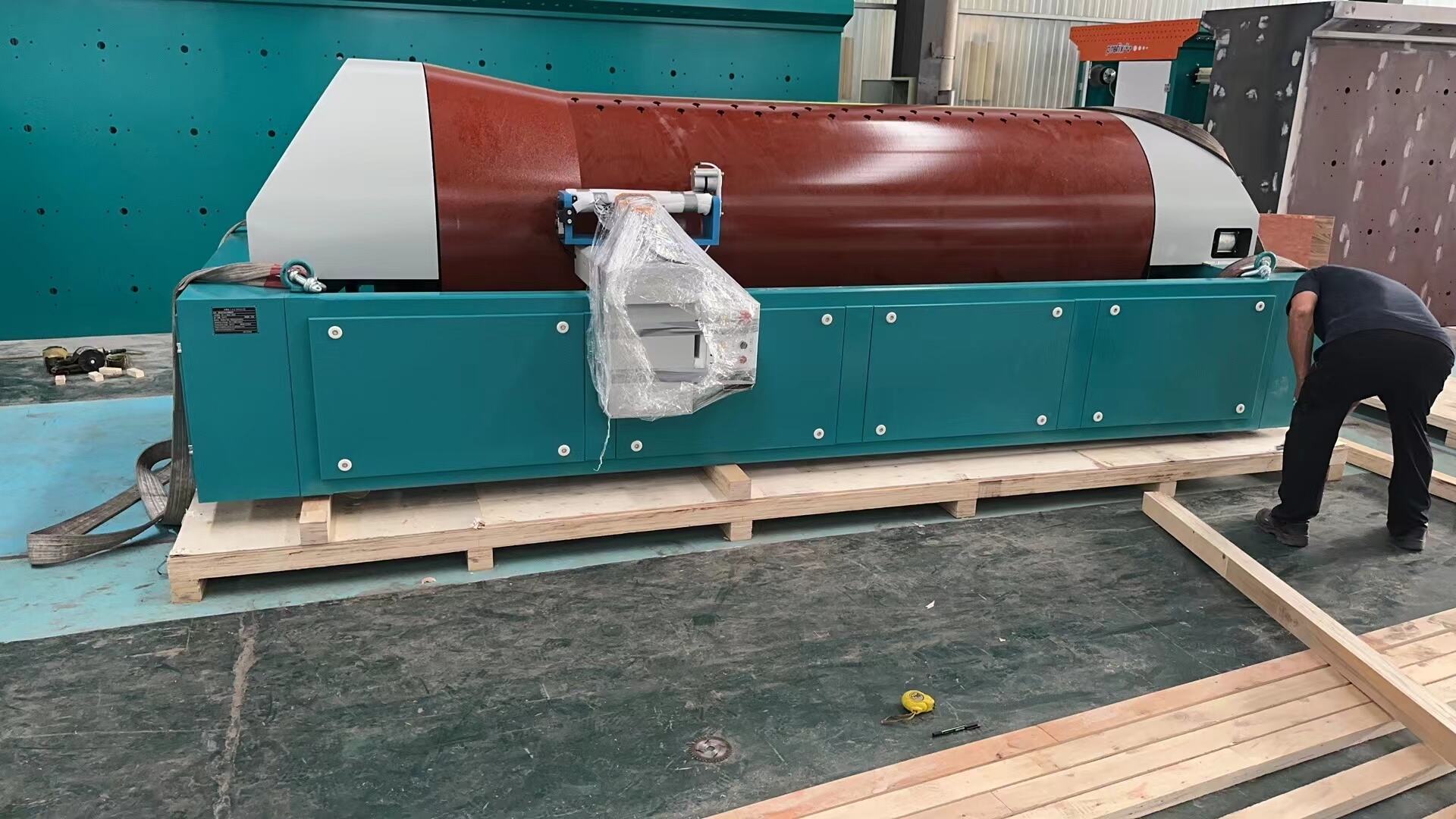

Introducing the Hot Sale Advanced Fully Automatic Mother Yarn Warping Splitting Machine from - the perfect addition to your textile manufacturing equipment lineup.

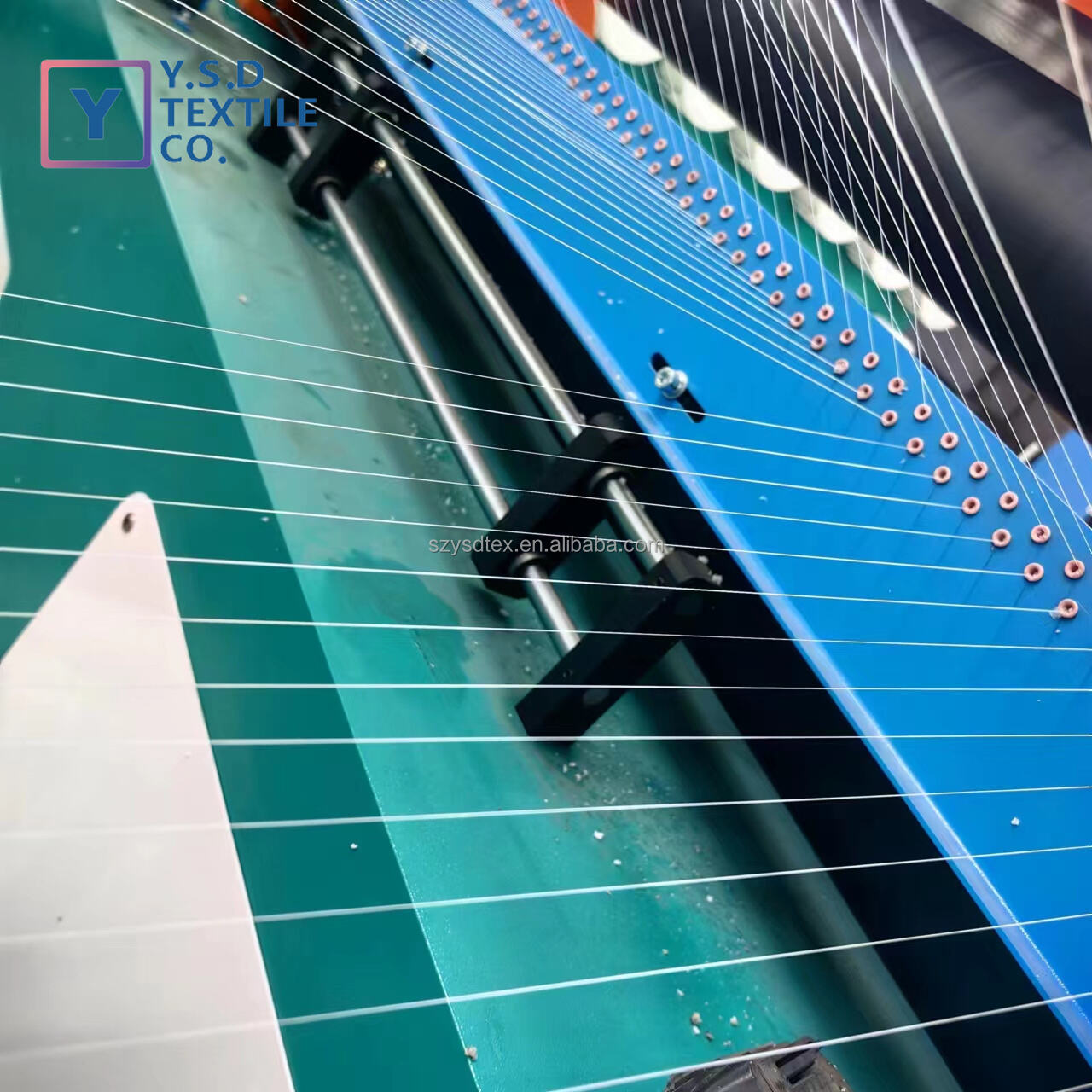

As the name suggests, this machine is fully automatic, which means you don't have to worry about manually dividing mother yarn into smaller sections. In fact, this machine can divide yarn into up to 32 smaller sections at once. This high speed auto dividing feature is a game-changer, allowing you to produce more yarn in less time, translating into increased productivity and profitability for your business.

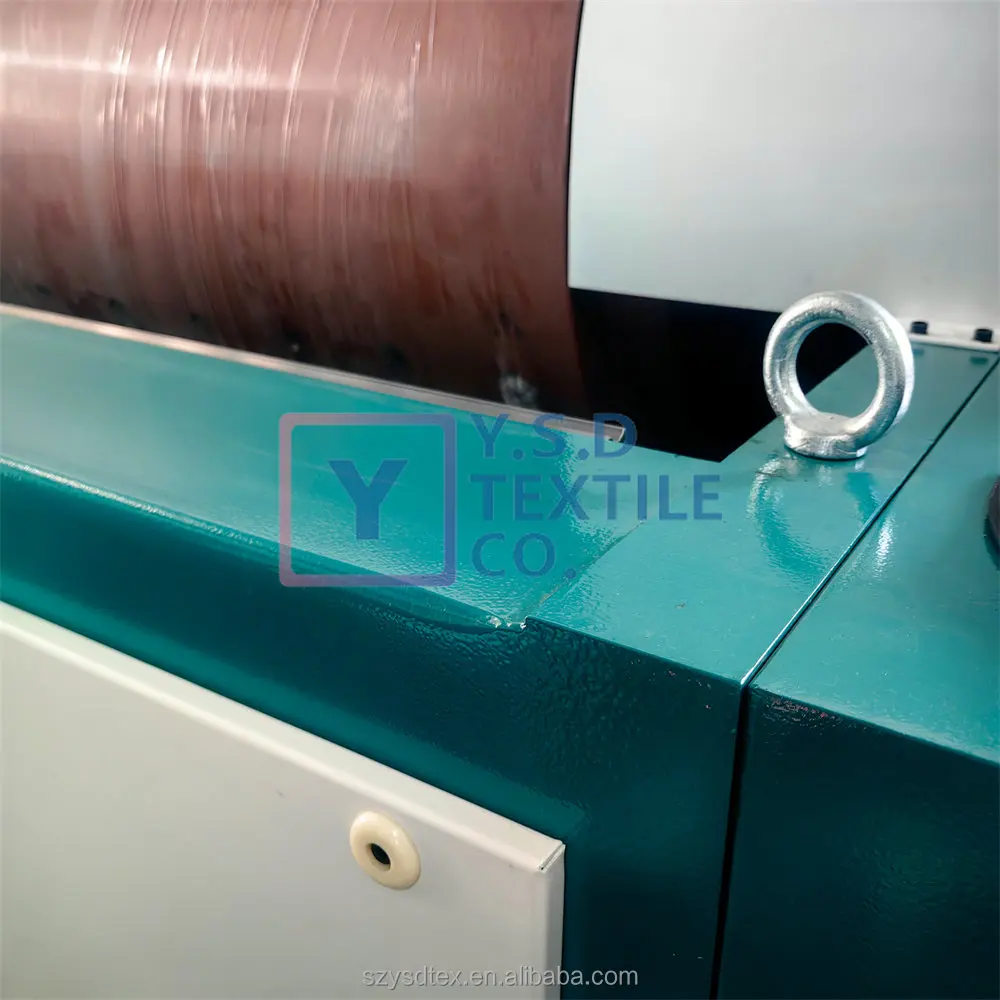

But what really sets this machine apart is its new core motor component. This component has been designed to increase efficiency, durability, and overall performance of the machine. You can count on this machine to deliver consistent and reliable results day in and day out.

But don't just take our word for it - let's talk about some of the other features and benefits of this machine. The Hot Sale Advanced Fully Automatic Mother Yarn Warping Splitting Machine is incredibly user-friendly and easy to operate. It has an intuitive control panel that allows you profixM to customize the settings to your specific needs. Additionally, this machine has been designed with safety in mind. It is equipped with multiple safety features, including automatic shutdown in case of malfunction.

Another benefit of this machine is its versatility. It can split a wide range of mother yarn types, including cotton, polyester, and nylon. And because it is fully automatic, it can handle a variety of different yarn diameters without any adjustments needed. This means you can easily switch between projects and yarn types with ease.

Finally, let's talk about the build quality of this machine. profixM is known for producing high-quality, durable machinery that stands the test of time. This machine is no exception. It has been constructed using only the best materials and components to ensure it can withstand even the toughest working conditions. And because it is backed by a comprehensive warranty, you can have peace of mind knowing that you are making a smart investment for your business.

if you are looking for a reliable, efficient, and versatile mother yarn warping and splitting machine, look no further than the Hot Sale Advanced Fully Automatic Mother Yarn Warping Splitting Machine from profixM. With its new core motor component, high speed auto dividing, user-friendly design, safety features, and versatility, this machine is a must-have for any textile manufacturing operation.

item |

value |

||||||

Applicable Industries |

Manufacturing Plant |

||||||

Name |

SECTIONAL MOTHER YARN SPLITTING WARPING MACHINE |

||||||

Video outgoing-inspection |

Provided |

||||||

Machinery Test Report |

Provided |

||||||

Marketing Type |

New Product 2025 |

||||||

Warranty of core components |

1 Year |

||||||

Place of Origin |

China, Jiangsu |

||||||

Machine Type |

WARPING MACHINE |

||||||

Material Capabilities |

NYLON/ POLYESTER FDY/ DTY MOTHER YARN |

||||||

Condition |

New |

||||||

Weight (KG) |

17000 |

||||||

Yarn Usage |

1t/day 240D/12F SD |

||||||

Warping max speed |

600m/min ON 240/12 SD NYLON MOTHER YARN |

||||||

warping servo moto |

7.5kw |

||||||

beam moto |

15kw |

||||||

warp beam max speed |

250m/min |

||||||

displacement servo |

1.5kw |

||||||

Front roller servo |

5.5kw |

||||||

Back roller servo |

4.5kw |

||||||

EN

EN

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

RO

RO

RU

RU

ES

ES

ID

ID

UK

UK

VI

VI

TH

TH

TR

TR

BN

BN

NE

NE