New Condition Sectional Warping Machine Making Polyester Nylon Textured Mother Yarn Essential Motor Manufacturing Plants

- Overview

- Inquiry

- Related Products

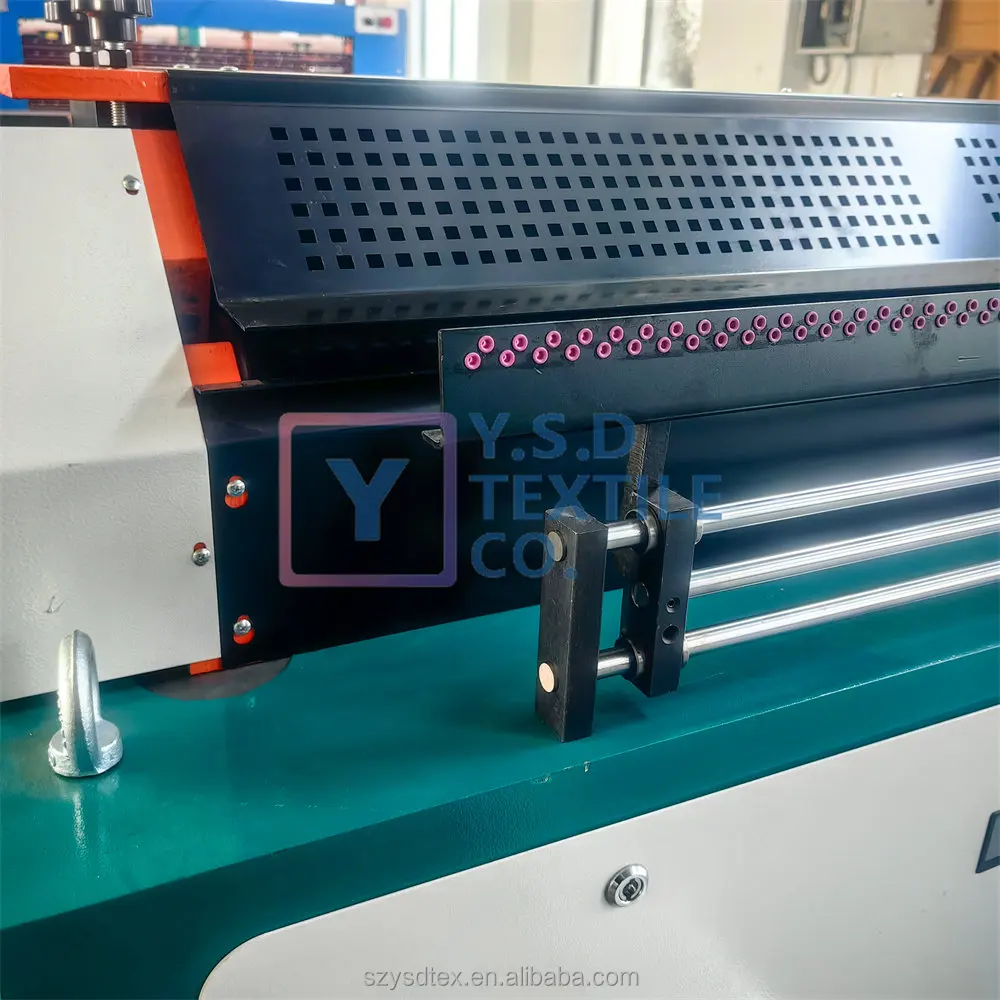

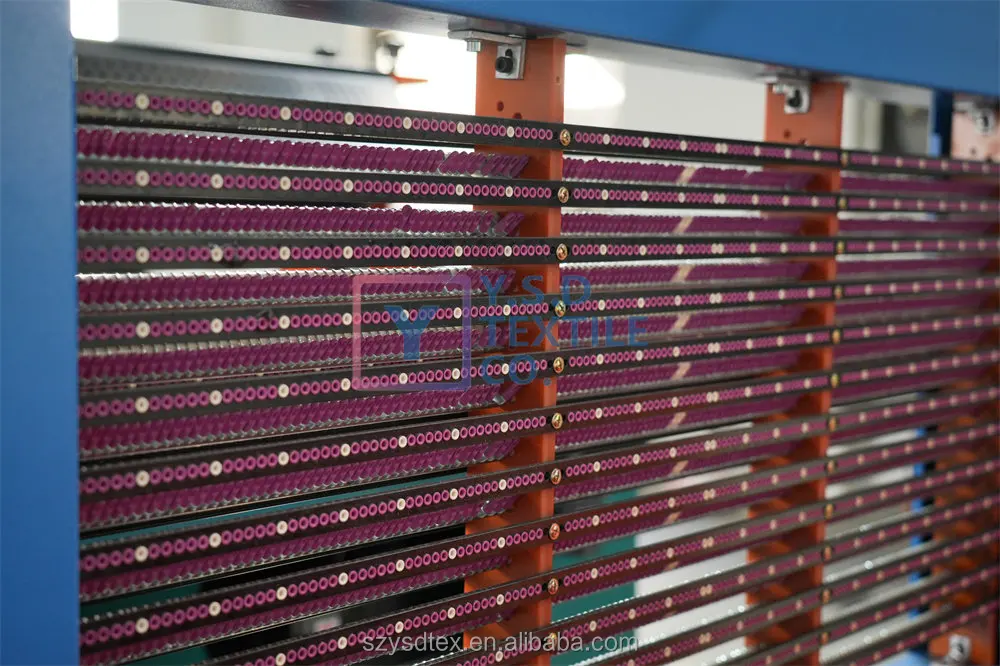

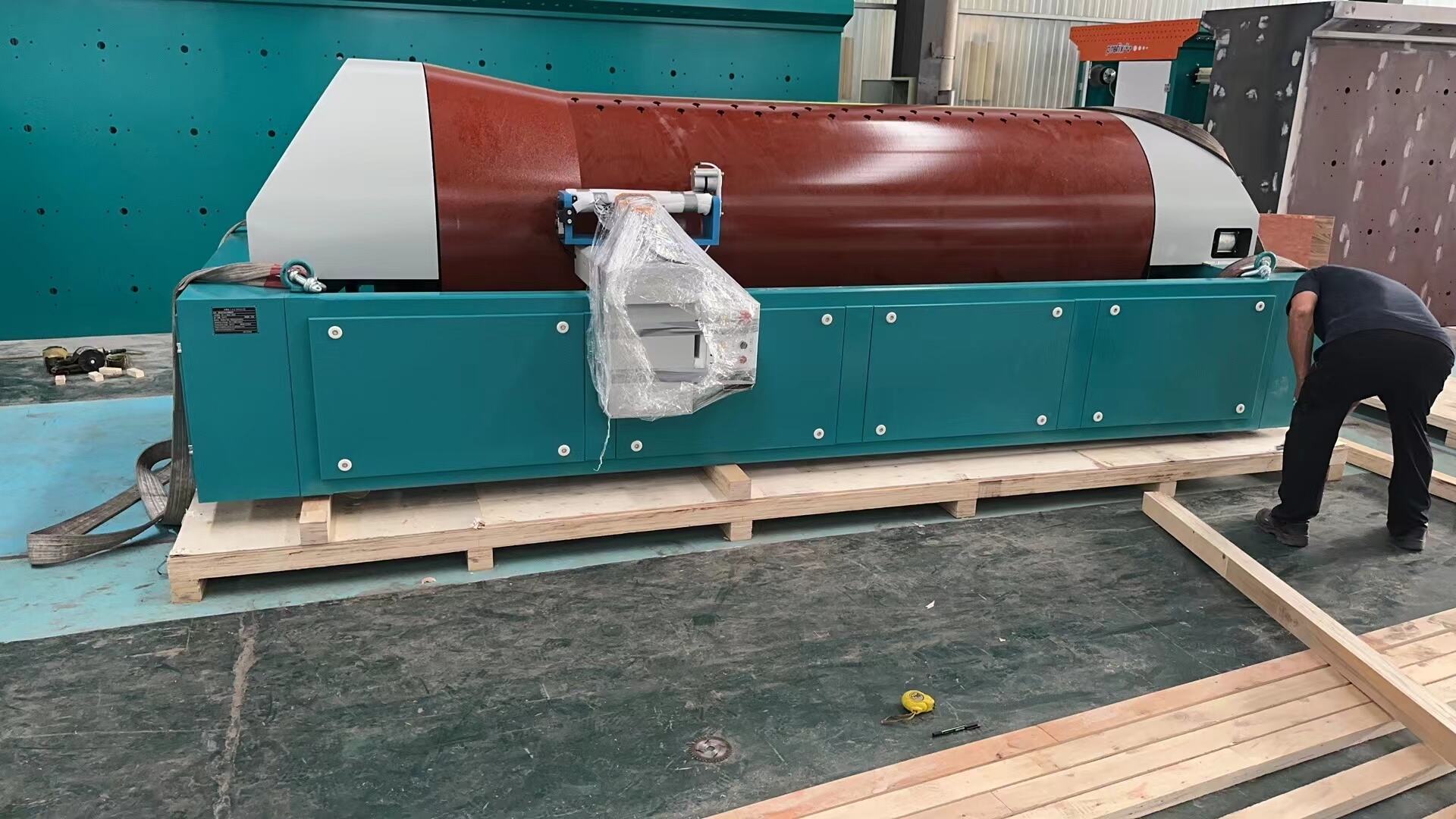

The profixM’s sectional warping machine is a must-have for any textile manufacturing plant. Made with high-quality materials and state-of-the-art technology, this machine is perfect for creating polyester and nylon textured mother yarn. With its easy-to-use interface and essential motor, this machine provides a consistent and efficient process that will save you time and money.

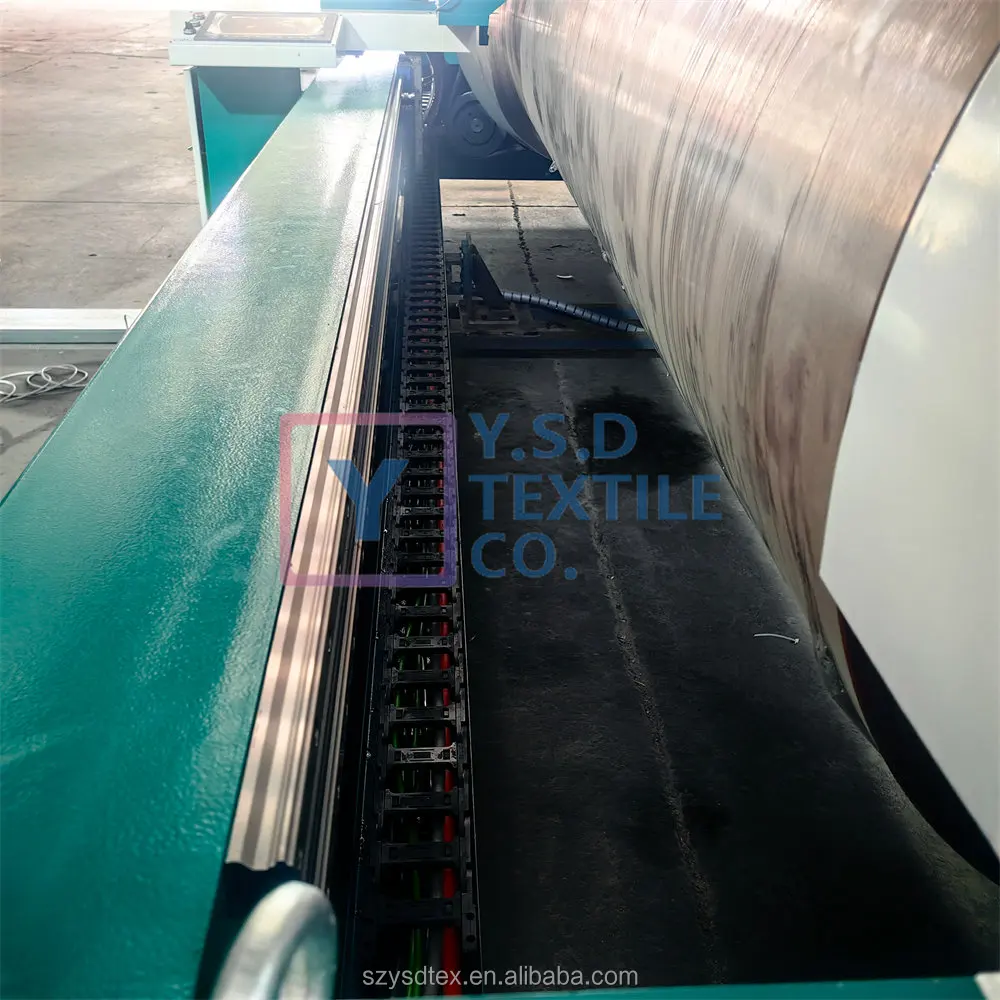

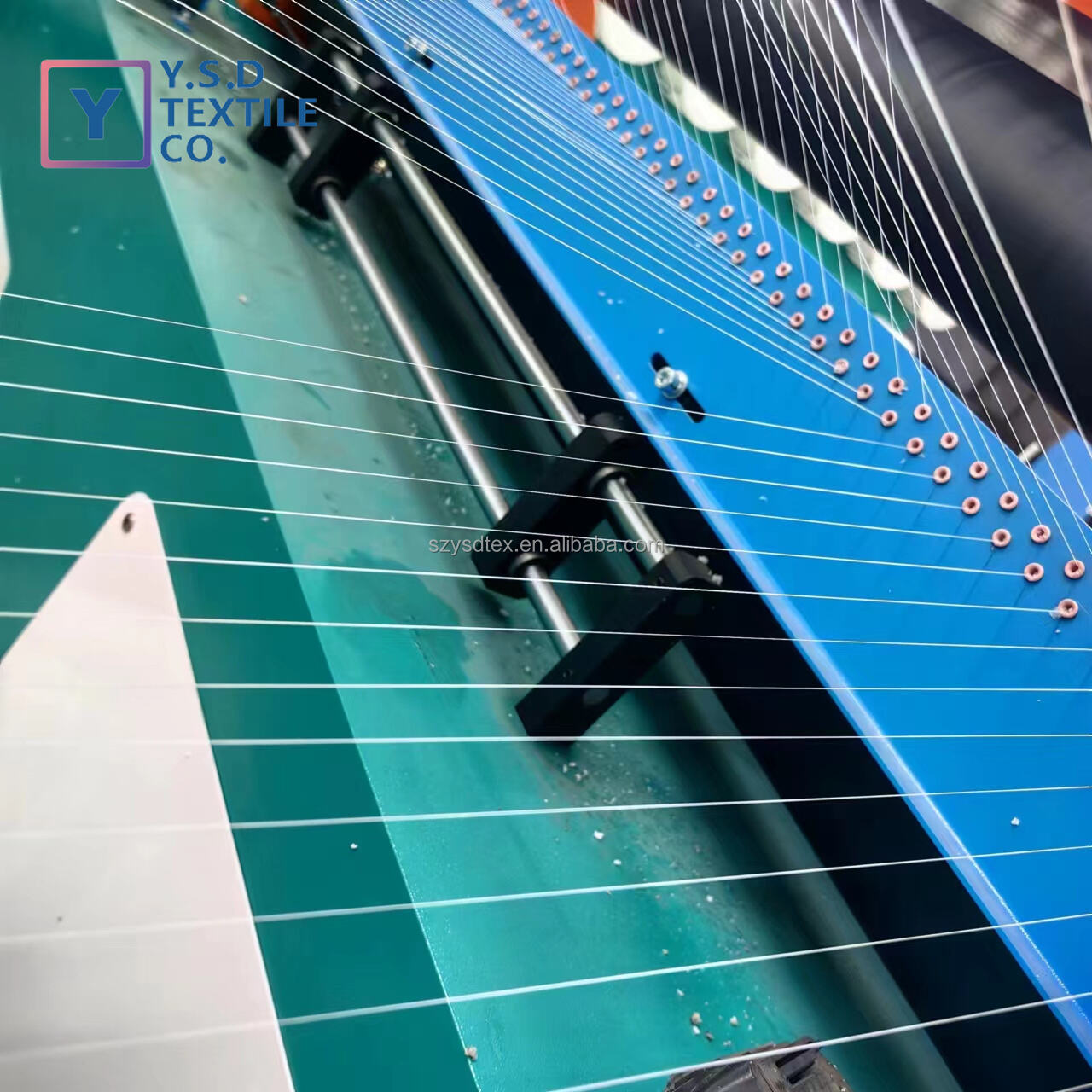

One of the key features of the profixM’s sectional warping machine is its ability to make high-quality mother yarn at a faster rate than traditional methods. This is thanks to its advanced technology that allows for rapid and accurate tension control. As a result, you can produce more yarn in less time, making your manufacturing process more efficient overall.

The machine features a sturdy construction that is built to withstand the rigors of daily use. The frame is made of high-quality materials that are resistant to corrosion, wear and tear, and other forms of damage. This ensures that the machine will last for years to come, even with heavy use.

Another great feature of the profixM’s sectional warping machine is its ease of use. The interface is simple and intuitive, so operators can quickly learn how to use it. The essential motor also makes the process more efficient by automating certain tasks, such as the winding of the yarn onto the cones.

The machine is also highly customizable, so you can fine-tune it to your specific needs. This means that you can adjust the machine to create yarns of varying sizes and textures, depending on your customers' requirements.

The profixM’s sectional warping machine is an essential tool for any textile manufacturing plant. It provides a consistent and efficient process for creating high-quality polyester and nylon textured mother yarn. With its advanced technology and easy-to-use interface, this machine is sure to enhance the productivity and profitability of your business. So, why not invest in one today and see the difference it can make

item |

value |

||||||

Applicable Industries |

Manufacturing Plant |

||||||

Name |

SECTIONAL MOTHER YARN SPLITTING WARPING MACHINE |

||||||

Video outgoing-inspection |

Provided |

||||||

Machinery Test Report |

Provided |

||||||

Marketing Type |

New Product 2025 |

||||||

Warranty of core components |

1 Year |

||||||

Place of Origin |

China, Jiangsu |

||||||

Machine Type |

WARPING MACHINE |

||||||

Material Capabilities |

NYLON/ POLYESTER FDY/ DTY MOTHER YARN |

||||||

Condition |

New |

||||||

Weight (KG) |

13500 |

||||||

Yarn Usage |

1t/day 240D/12F SD |

||||||

Warping max speed |

600m/min ON 240/12 SD NYLON MOTHER YARN |

||||||

warping servo moto |

7.5kw |

||||||

beam moto |

15kw |

||||||

warp beam max speed |

250m/min |

||||||

displacement servo |

1.5kw |

||||||

Front roller servo |

5.5kw |

||||||

Back roller servo |

4.5kw |

||||||

1) The warping machine has the characteristics of high efficiency, stability, and reliability, which can greatly improve the production efficiency of the textile industry

2) Its high precision and consistency ensure the quality of the fabric, making it more neat and uniform

3) The warping machine is widely used in the textile industry and is one of the very important production equipment in textile factories

Q:How to place machines order

A:Please send us your purchase order by email, whatsapp or wechat. We need to know the following information for your order:

(1) Your products width and thickness - webbing, tapes, lace width and thickness

(2) Price Item, Destination Port, Delivery time required

(3) Shipping information: Company Name, Address, Phone Number, Destination Seaport/Airport

Q:What are the payment terms

A:For orders, we can accept T/T, L/C at sight

Q:How many years of producing these machine

---We produced these machine for more than 15 years.

EN

EN

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

RO

RO

RU

RU

ES

ES

ID

ID

UK

UK

VI

VI

TH

TH

TR

TR

BN

BN

NE

NE