New Condition Splitting Warping Machine for Manufacturing Plant Core Component Motor Used Making Warping Beam Mother Yarn

- Overview

- Inquiry

- Related Products

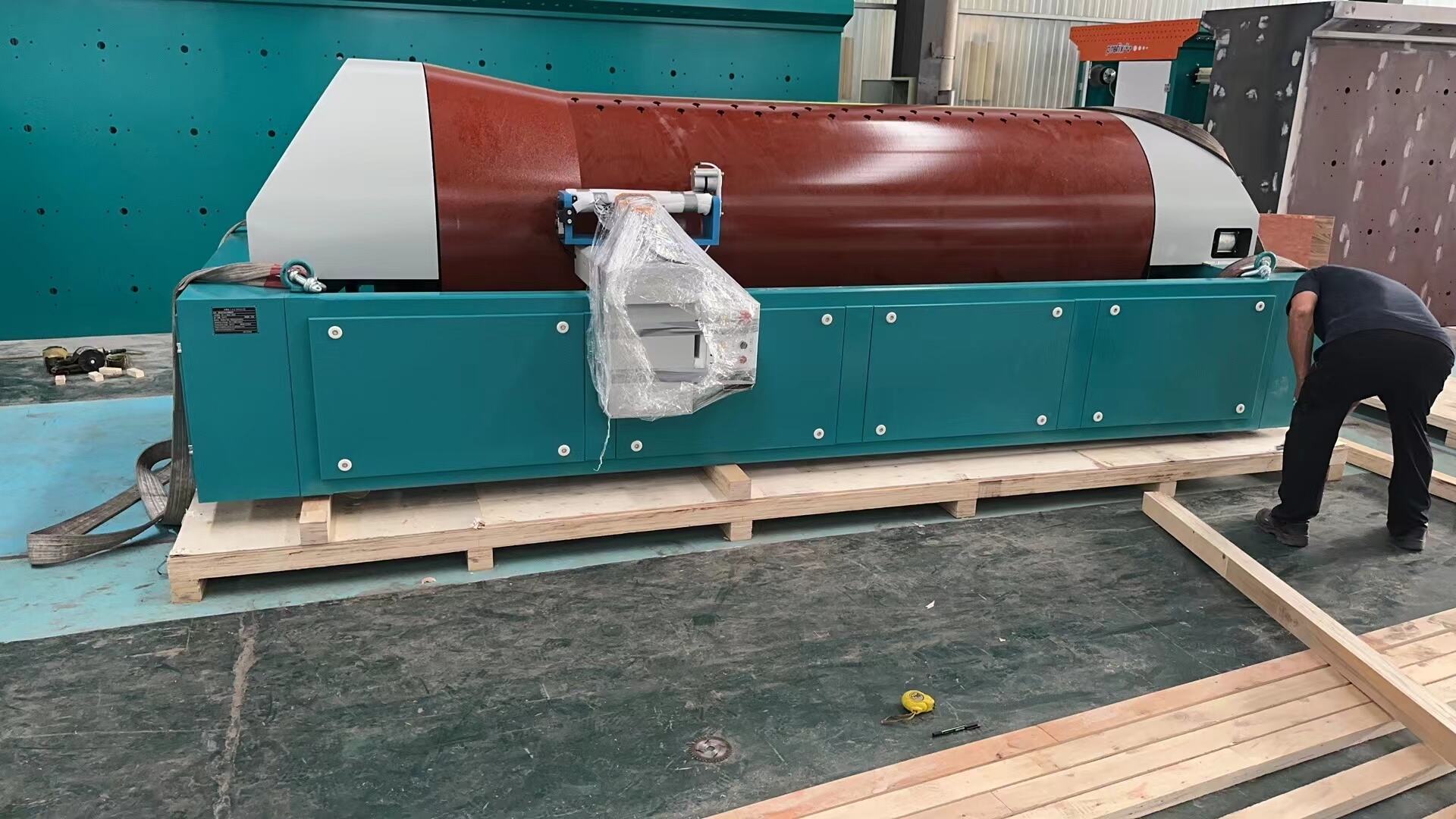

Introducing, the New Condition Splitting Warping Machine by ProfixM! This state-of-the-art piece of equipment is a must-have for any manufacturing plant looking to streamline their warping process.

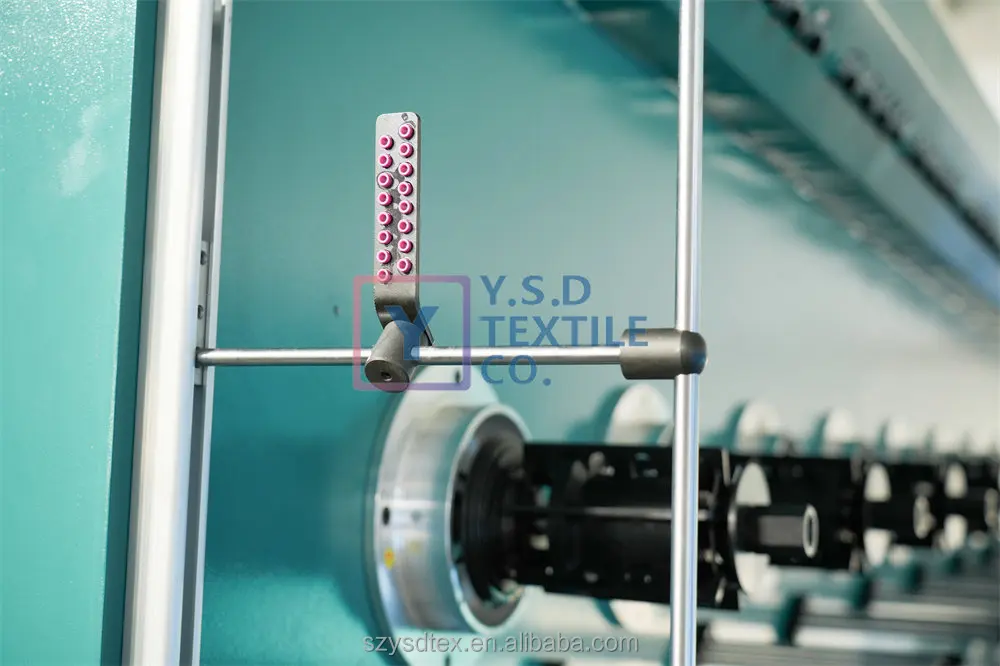

Featuring a powerful core component motor, this machine is designed to efficiently produce warping beams from mother yarn. The motor is specifically chosen for its reliability and durability, ensuring that it can withstand even the toughest of manufacturing conditions.

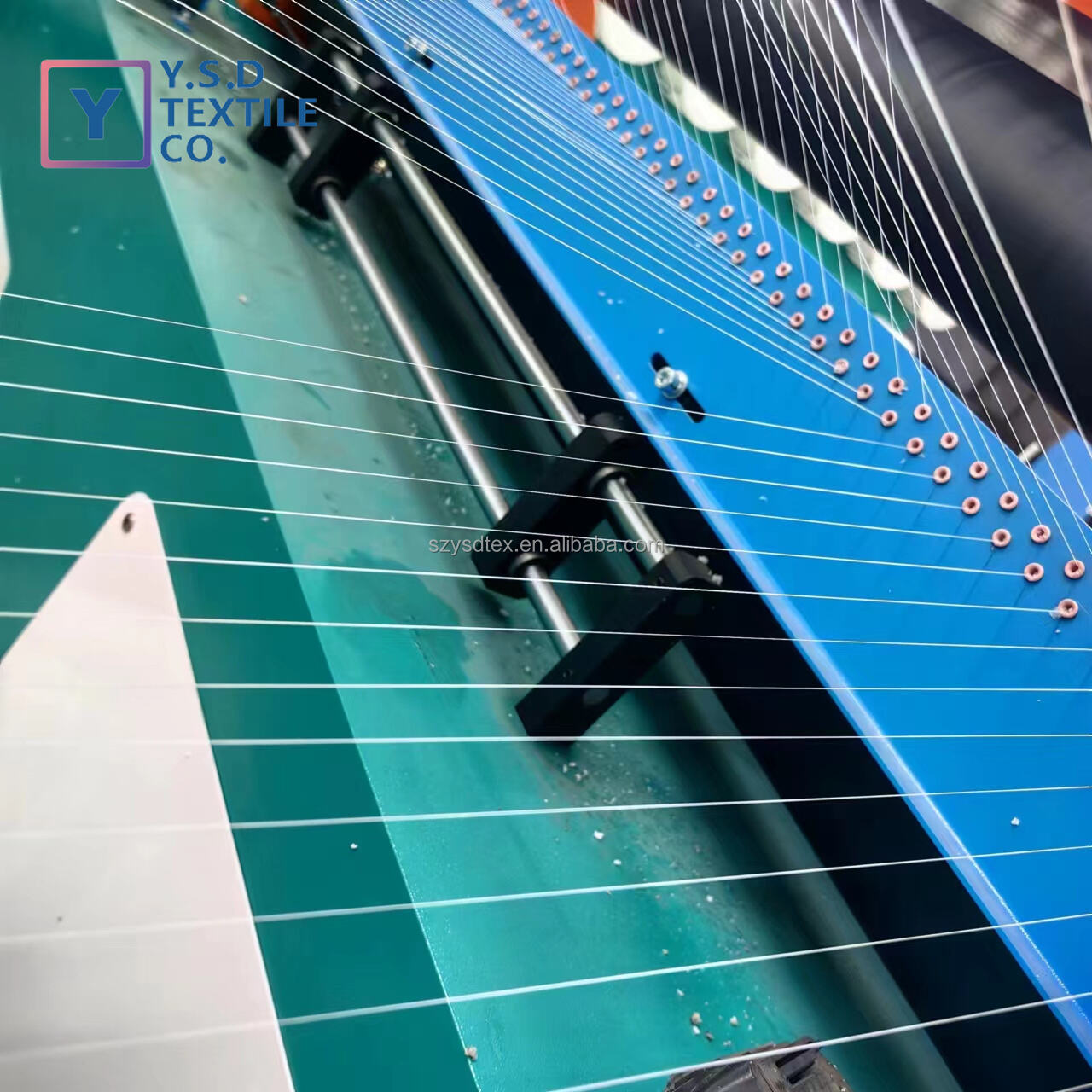

The splitting warping machine boasts advanced technology that allows it to easily and accurately split the mother yarn into the desired number of ends. This not only saves time but also ensures consistency in each warping beam produced.

Furthermore, the machine is designed with the operator in mind. It features intuitive controls that make operating it easy and effortless. The sleek design also makes it easy to maintain and clean after use, making it an ideal investment for any manufacturing plant looking to improve their production capacity.

ProfixM is a brand that is well-known for its quality products and outstanding customer service. With the new condition splitting warping machine, the brand has once again lived up to its reputation by providing a product that is reliable, efficient and easy to use.

Manufacturers can expect to see a notable increase in production capacity with this machine. The splitting warping machine is perfect for use in the production of textiles, fabrics, and other woven materials.

Investing in the new condition splitting warping machine is an investment that will pay off in the long run. The robust motor, precise splitting technology, and easy-to-use controls make it an essential piece of equipment for any manufacturing plant looking to improve their warping process.

Don't miss out on this opportunity to streamline your production process. Get the new condition splitting warping machine by ProfixM and take your production capacity to the next level

item |

value |

||||||

Applicable Industries |

Manufacturing Plant |

||||||

Name |

SECTIONAL MOTHER YARN SPLITTING WARPING MACHINE |

||||||

Video outgoing-inspection |

Provided |

||||||

Machinery Test Report |

Provided |

||||||

Marketing Type |

New Product 2023 |

||||||

Warranty of core components |

1 Year |

||||||

Place of Origin |

China, Jiangsu |

||||||

Machine Type |

WARPING MACHINE |

||||||

Material Capabilities |

NYLON/ POLYESTER FDY/ DTY MOTHER YARN |

||||||

Condition |

New |

||||||

Weight (KG) |

17000 |

||||||

Yarn Usage |

1t/day 240D/12F SD |

||||||

Warping max speed |

600m/min ON 240/12 SD NYLON MOTHER YARN |

||||||

warping servo moto |

7.5kw |

||||||

beam moto |

15kw |

||||||

warp beam max speed |

180m/min |

||||||

displacement servo |

1.5kw |

||||||

Front roller servo |

5.5kw |

||||||

Back roller servo |

4.5kw |

||||||

1) The warping machine has the characteristics of high efficiency, stability, and reliability, which can greatly improve the production efficiency of the textile industry.

2) Its high precision and consistency ensure the quality of the fabric, making it more neat and uniform.

3) The warping machine is widely used in the textile industry and is one of the very important production equipment in textile factories

Q:How to place machines order

A:Please send us your purchase order by email, whatsapp or wechat. We need to know the following information for your order:

(1) Your products width and thickness(webbing, tapes, lace width and thickness)

(2) Price Item, Destination Port, Delivery time required

(3) Shipping information: Company Name, Address, Phone Number, Destination Seaport/Airport

Q:What are the payment terms

A:For orders, we can accept T/T, L/C at sight

Q:How many years of producing these machine

---We produced these machine for more than 15 years

EN

EN

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

RO

RO

RU

RU

ES

ES

ID

ID

UK

UK

VI

VI

TH

TH

TR

TR

BN

BN

NE

NE