New Condition Yarn Sectional Split Warping Machine Core Component Motor for Manufacturing Plant

- Overview

- Inquiry

- Related Products

ProfixM

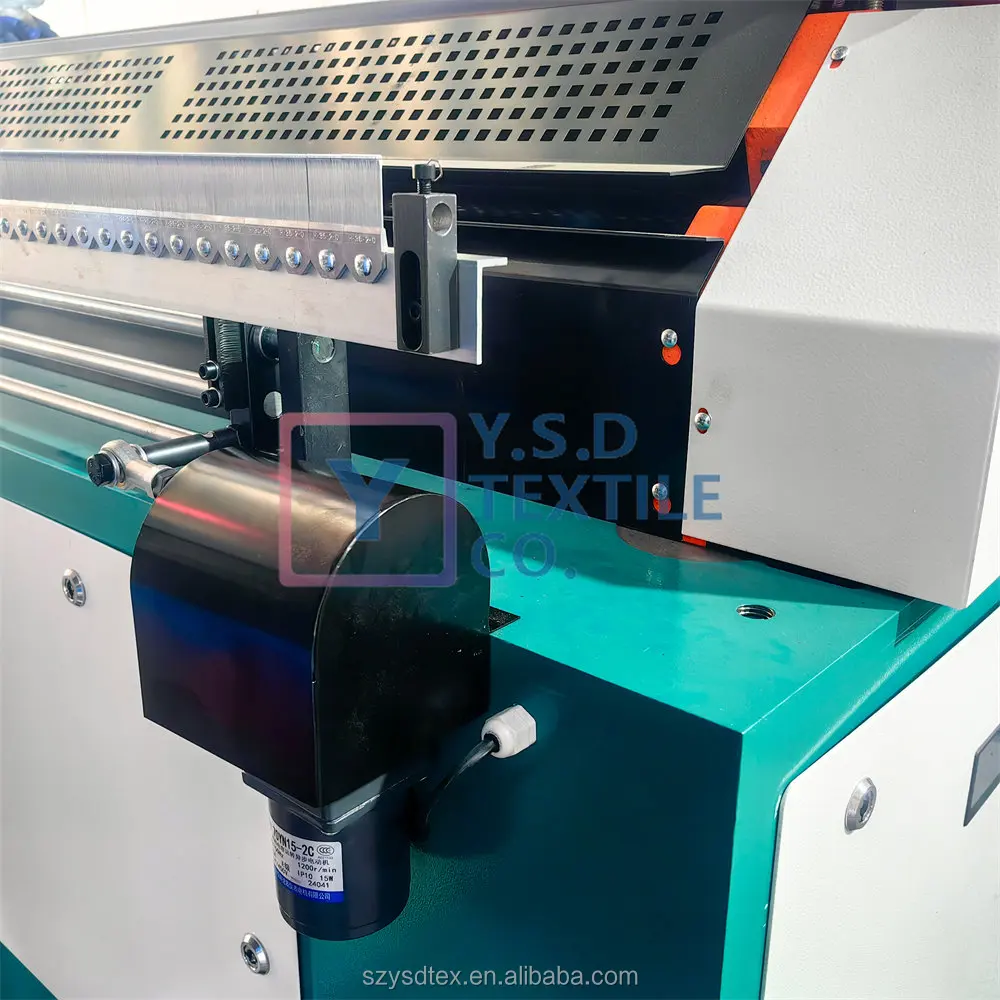

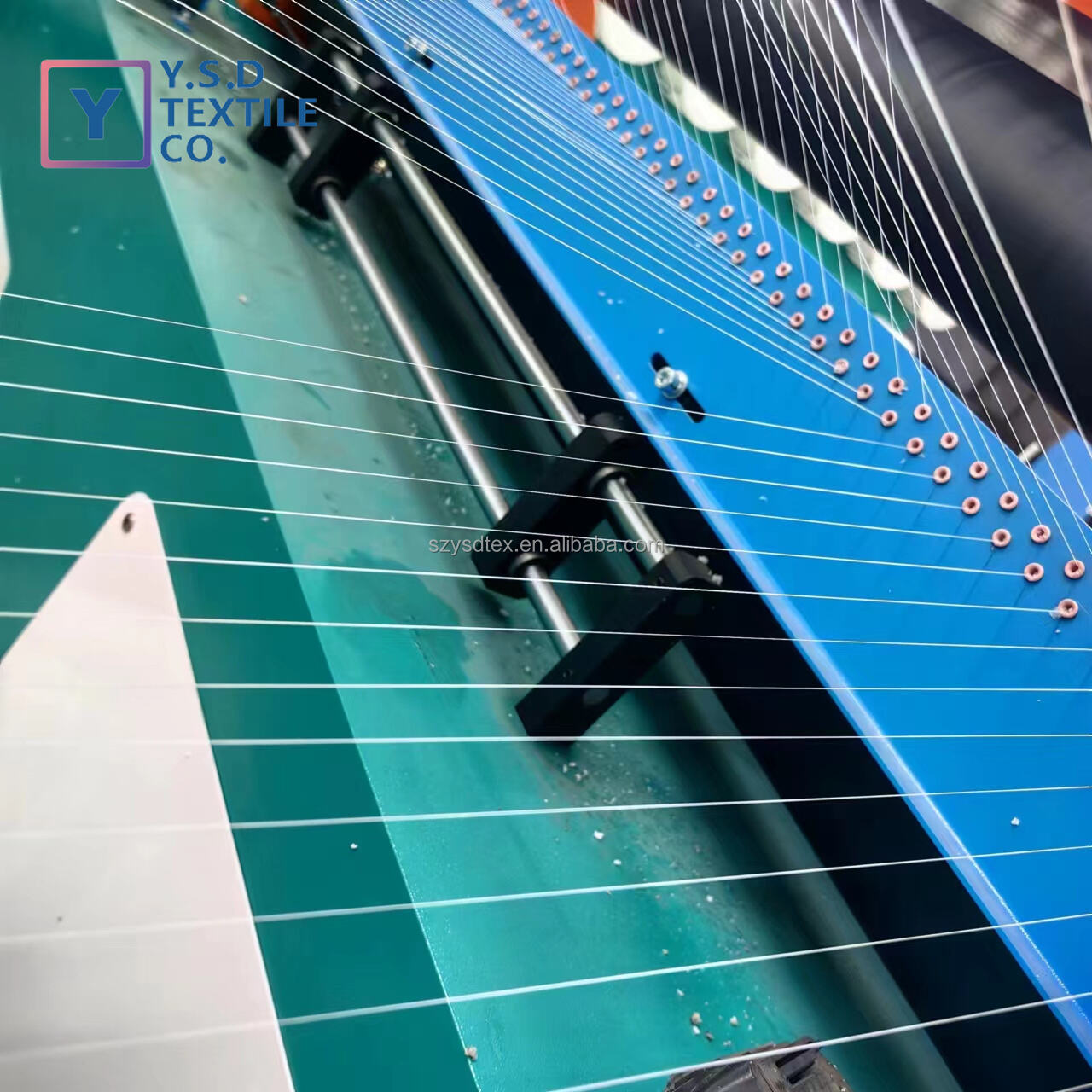

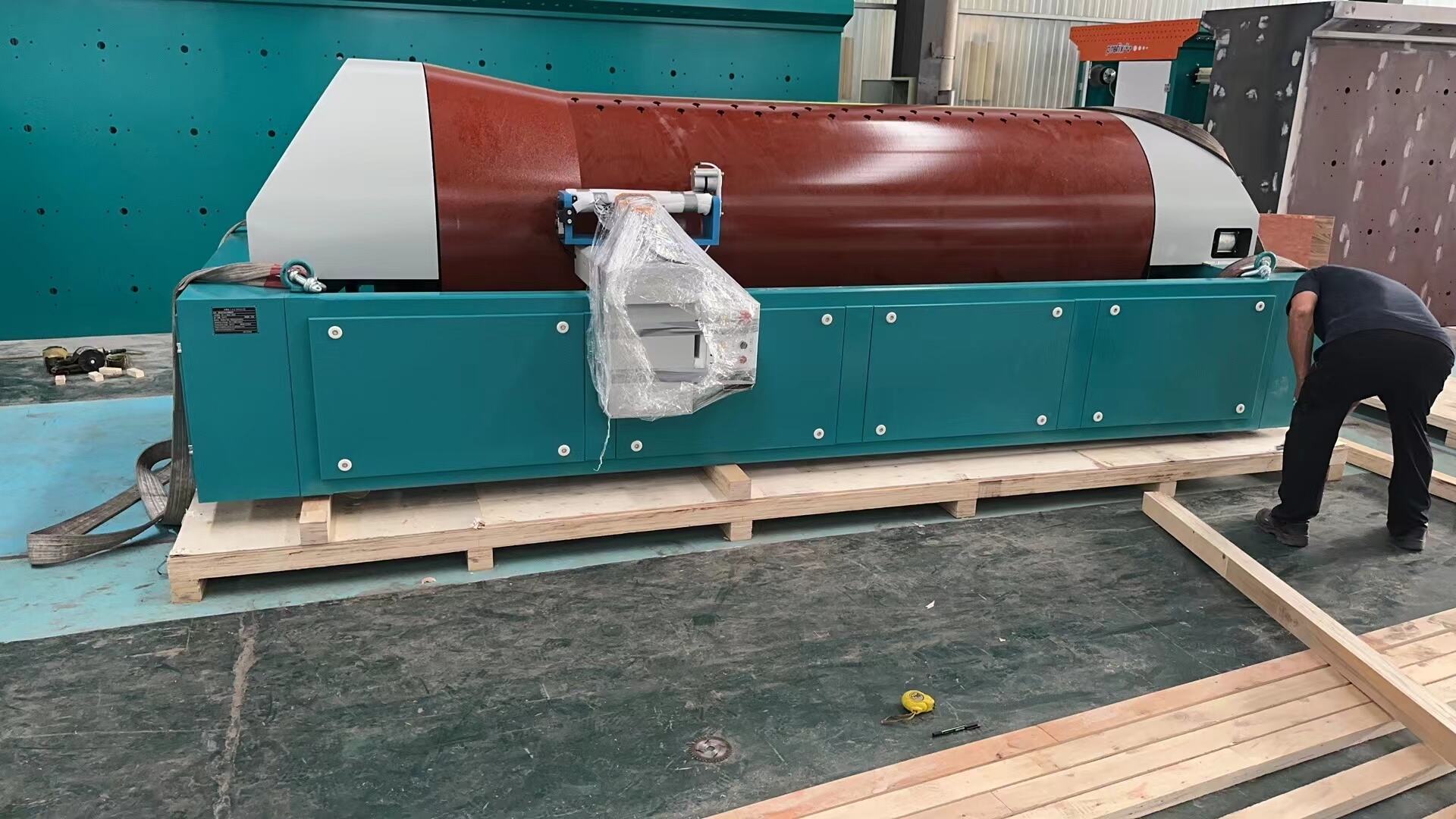

Introducing the latest innovation in yarn manufacturing - the New Condition Yarn Sectional Split Warping Machine Core Component Motor! This high-performing motor is specially designed for manufacturing plants that produce yarn for various textiles and garments.

The ProfixM motor is a core component of the sectional split warping machine, which is responsible for accurately and efficiently winding yarn onto a warp beam. With this top-of-the-line motor, you can rest assured that your production process will run smoothly and quickly.

The motor is built with the profixM latest technology and has been rigorously tested to ensure durability and reliability. It is able to withstand the harsh conditions of a manufacturing plant and still remain efficient and effective. This means that you won't have to worry about equipment breakdowns or time-consuming repairs, which can cut into your productivity and profits.

Additionally, the ProfixM motor is designed with user in mind. It has a simple interface that makes it easy to install and operate, even for those who may be new to the industry. The motor comes with detailed instructions and technical support to ensure that you have all the necessary information to get it up and running quickly.

One of the biggest advantages of the ProfixM motor is its energy efficiency. It consumes less power compared to other motors and can help reduce your energy costs. This makes it both an eco-friendly and cost-efficient option for your manufacturing plant.

The ProfixM New Condition Yarn Sectional Split Warping Machine Core Component Motor is a revolution in yarn manufacturing technology. It is a durable, reliable, and energy-efficient motor that can help boost your production volume and reduce costs. If you're looking for a high-performing motor that will keep your manufacturing plant running smoothly, look no further than ProfixM.

item |

value |

product |

MACHINE |

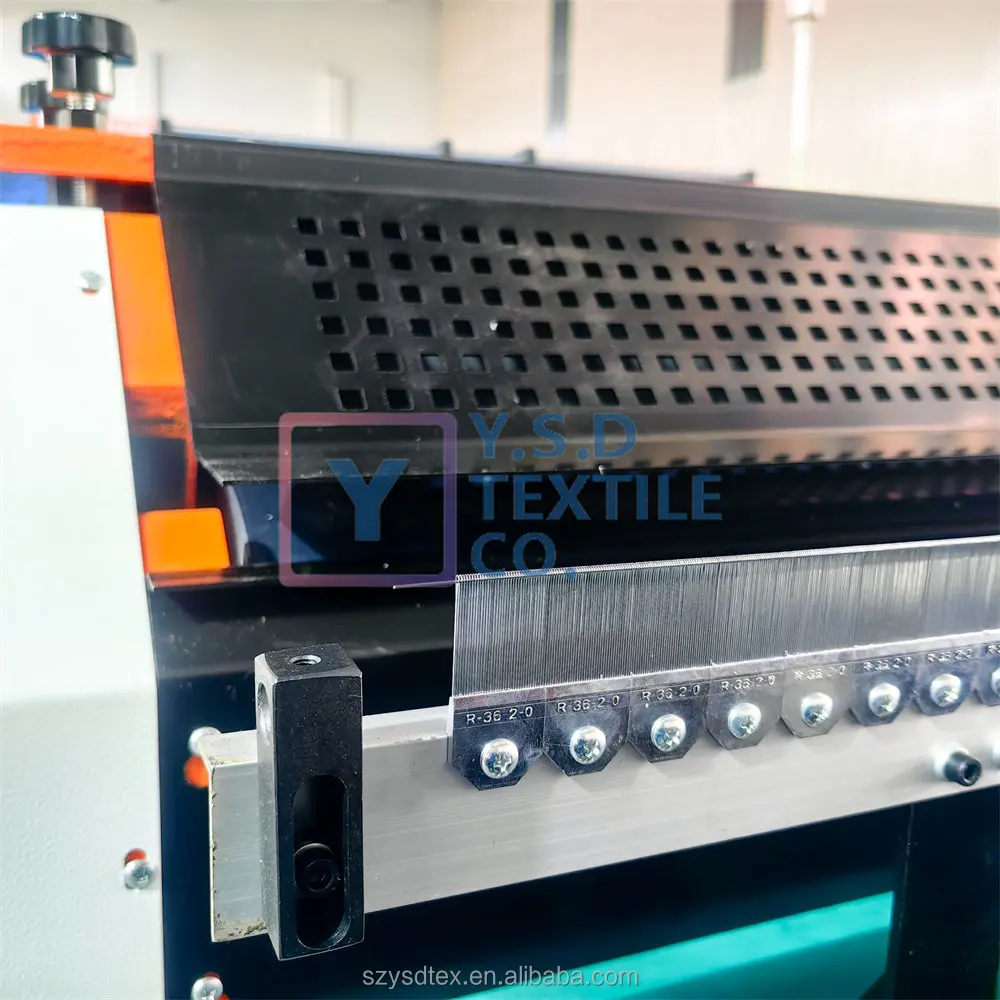

material capabilities |

NYLON/POLYESTER MOTHER YARN |

weight (kg) |

13500 |

machine type |

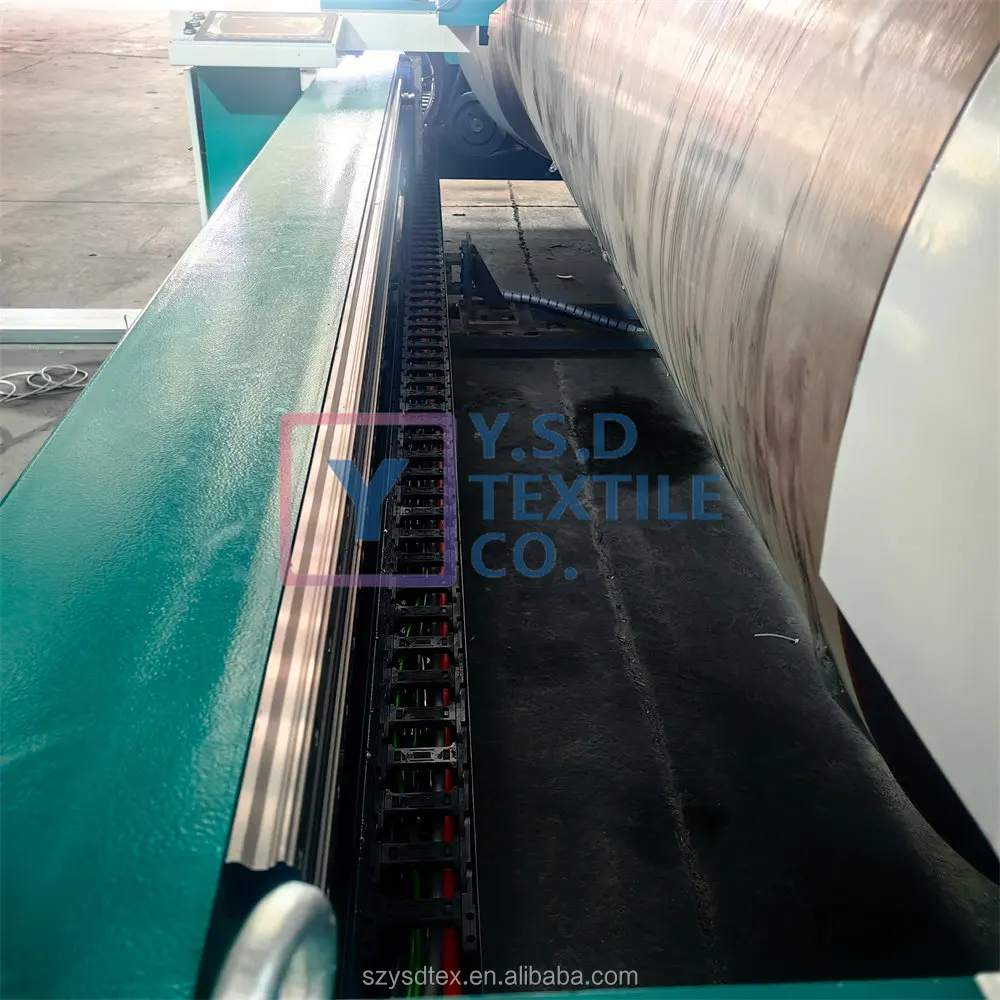

WARPING MACHINE |

video outgoing-inspection |

Provided |

machinery test report |

Provided |

core components |

Engine |

place of origin |

China |

Jiangsu |

|

warranty |

1 Year |

Name |

splitting and Striping warping machine mother yarn warping machine |

Usage |

1t/day 240D/12F SD |

Warping max speed |

600m/min |

mother yarn tension |

0-500cn |

warping servo moto |

7.5kw |

beam moto |

15kw |

warp beam max speed |

180m/min |

displacement servo |

1.5kw |

Front roller servo |

5.5kw |

Back roller servo |

4.5kw |

EN

EN

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

RO

RO

RU

RU

ES

ES

ID

ID

UK

UK

VI

VI

TH

TH

TR

TR

BN

BN

NE

NE