ProfixM

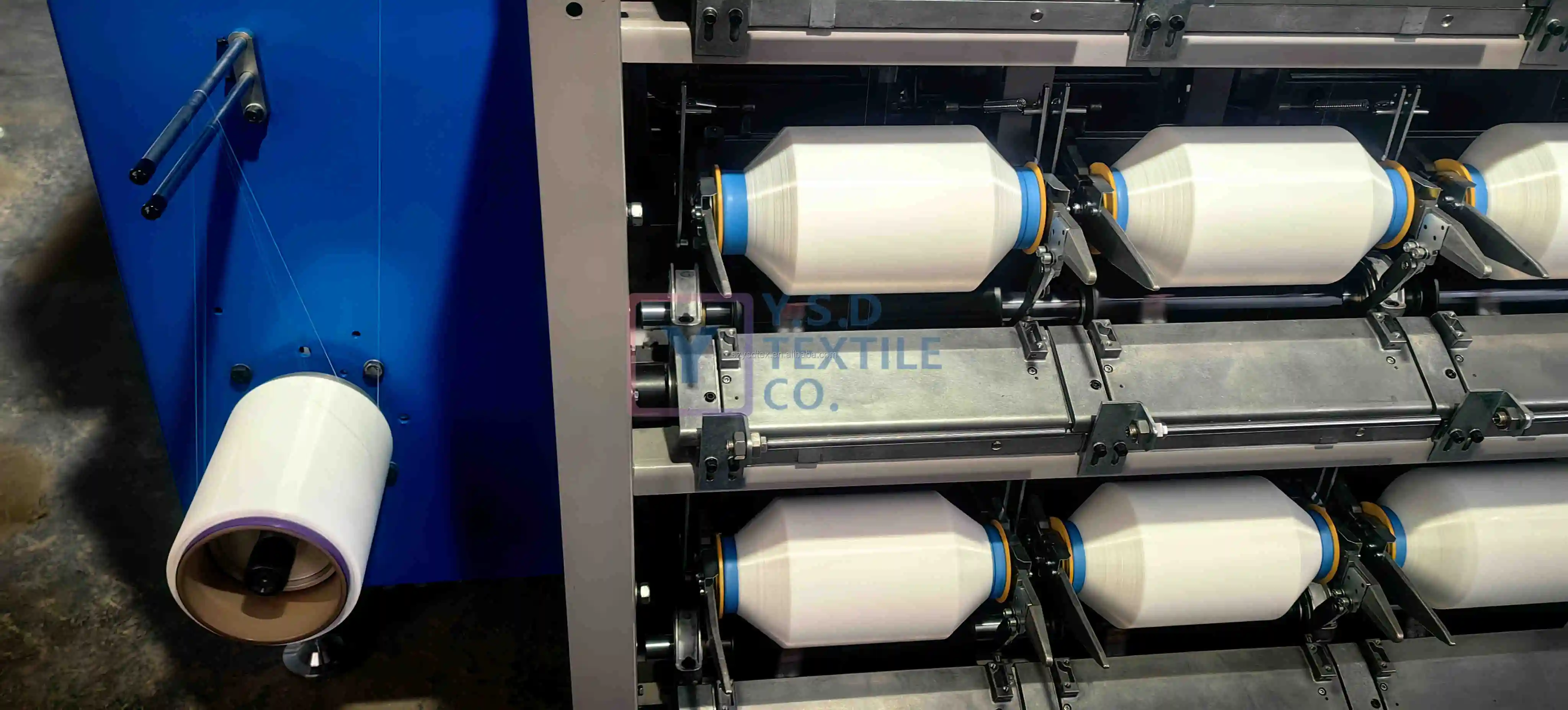

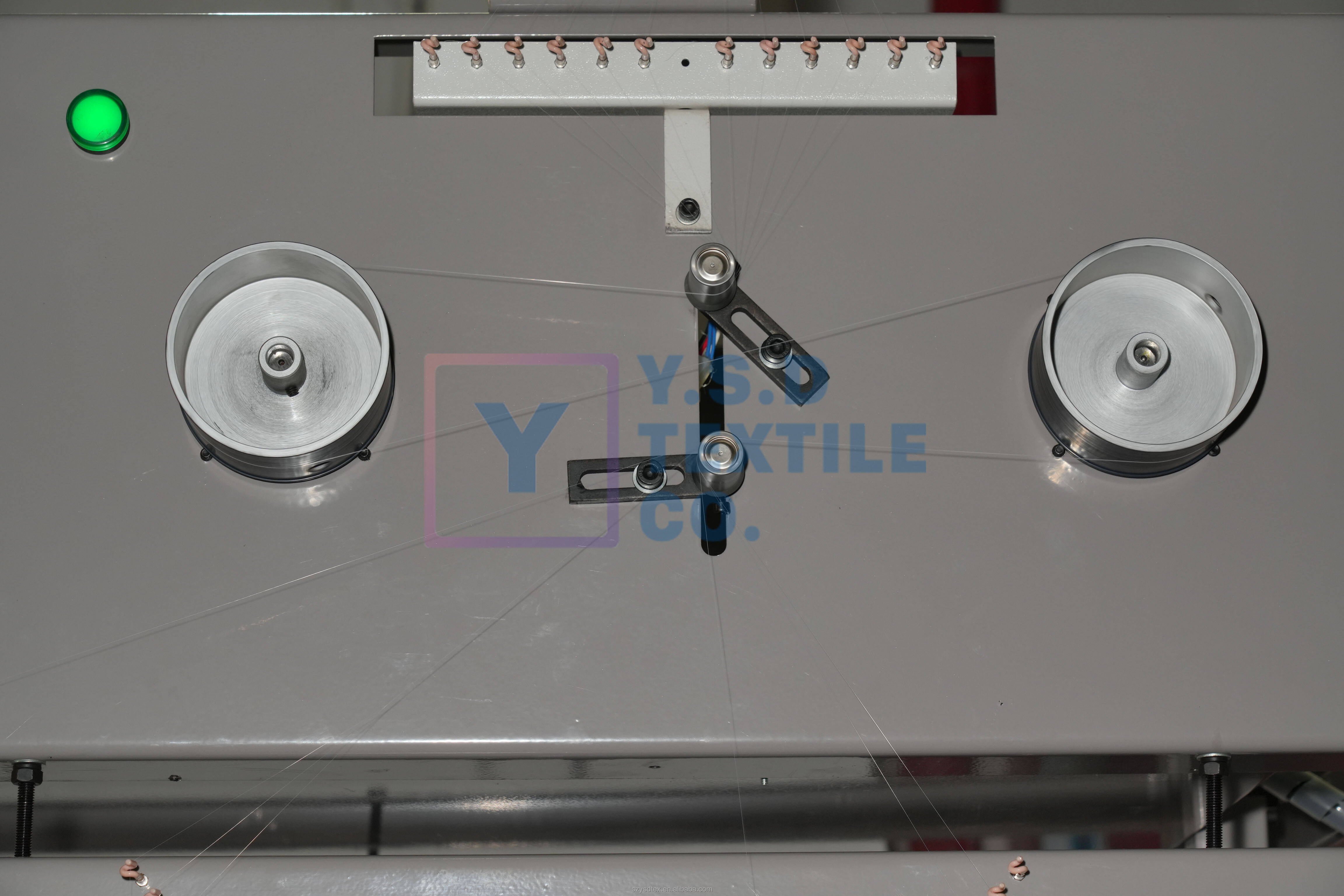

Introducing the latest innovation in the world of manufacturing plants - The New Manufacturer Nylon Polyester Mother Yarn Splitting Machine with Rolling Paper, brought to you by the brand. This machine is designed to split mother yarn into multiple thin yarn strands creating an efficient process for yarn production.

One of the key components of this machine is its core component motor. The motor is the driving force that powers the machine’s mechanisms, and it is built to last. It is specifically designed to handle large production quantities without any degradation in performance. This ensures that the machine will maintain consistent performance levels over time, giving you reliable and consistent output.

With this machine, you no longer have to deal with the hassle of manually handling the splitting of mother yarn; it takes care of the process automatically. The profixM machine is designed to split the yarn evenly, with each strand being of the same thickness. This feature guarantees that the quality of the yarn produced is of the highest standard possible.

Another feature of the ProfixM Nylon Polyester Mother Yarn Splitting Machine is that it comes with a rolling paper feature. The rolling paper helps to keep the strands of yarn in parallel positions, which further enhances the quality of the yarn produced. The rolling paper also serves as a guide for consistent yarn strand thickness. This functionality combined with the automatic yarn splitting feature makes the ProfixM Nylon Polyester Mother Yarn Splitting Machine a reliable and efficient option for any yarn production plant.

The ProfixM Nylon Polyester Mother Yarn Splitting Machine is also very user-friendly. The machine is designed to be simple to operate, and you do not require any specialized knowledge to operate it. It is also easy to maintain, making it a low-maintenance investment for any manufacturing plant. This feature is especially important as it allows you to focus on other aspects of the production line while the machine handles the yarn splitting process.

The ProfixM Nylon Polyester Mother Yarn Splitting Machine is an excellent investment for any manufacturing plant that requires high-quality yarn production. The machine’s core component motor, automatic yarn splitting, rolling paper, and user-friendly design make it a top-notch choice for any yarn manufacturing business. So why not upgrade your plant today by investing in the ProfixM Nylon Polyester Mother Yarn Splitting Machine with Rolling Paper?

item |

value |

product |

Machine |

material capabilities |

Nylon and polyester mono yarn |

weight (kg) |

600 |

machine type |

Mother yarn splitting machine |

video outgoing-inspection |

Provided |

machinery test report |

Provided |

core components |

Engine |

place of origin |

China |

|

Jiangsu |

warranty |

1 Year |

Name |

Mother yarn splitting machine |

Winding coil skeleton |

95-130x230mm |

Splitting tension |

0.6g/d- 1.0g/d |

Winding |

120*2300mm |

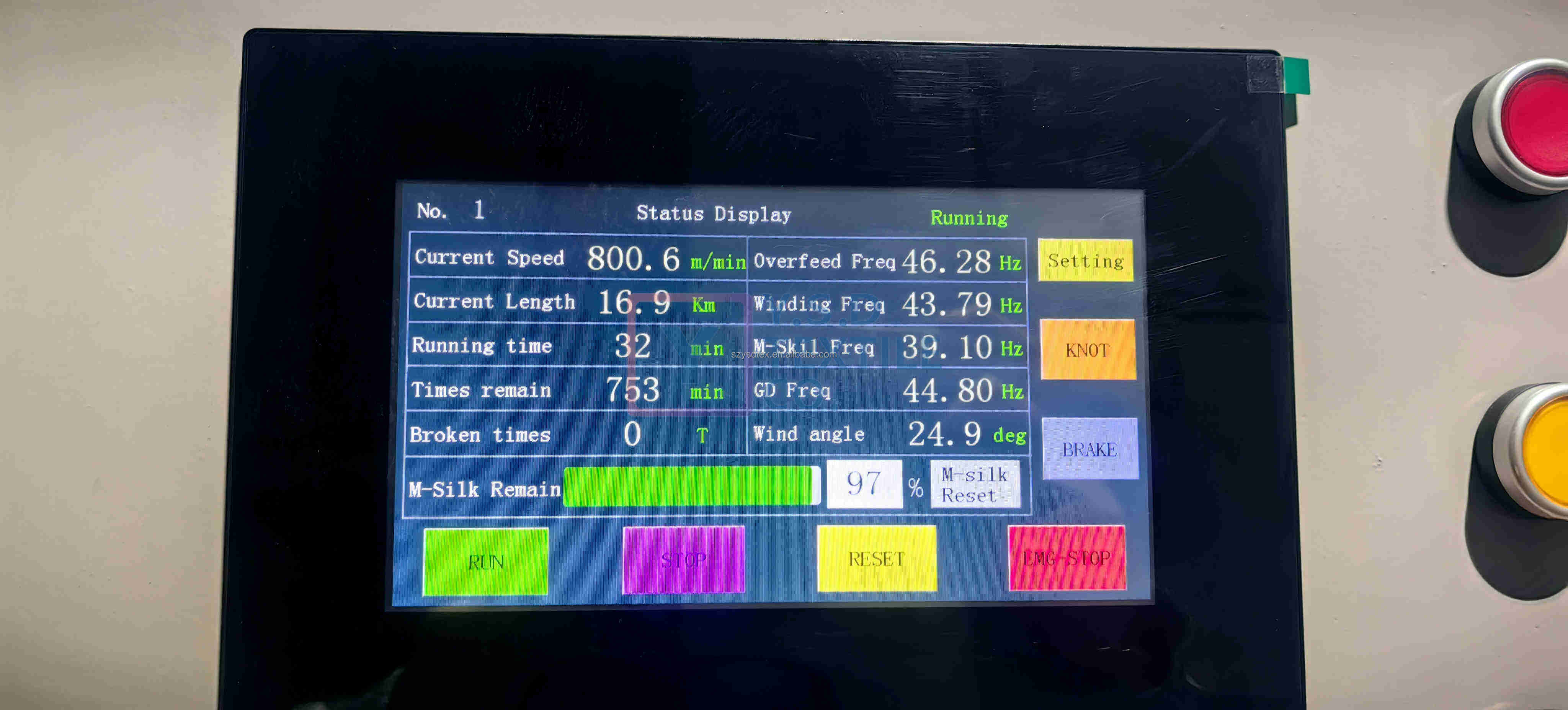

splitting speed |

200D/10F can reach 800/min |

Forming device |

100mm-460mm |

Spindle motor |

1kw |

Wire feed motor |

0.24kw |

Forming motor |

0.02kw |

Spitting motor |

0.02kw |

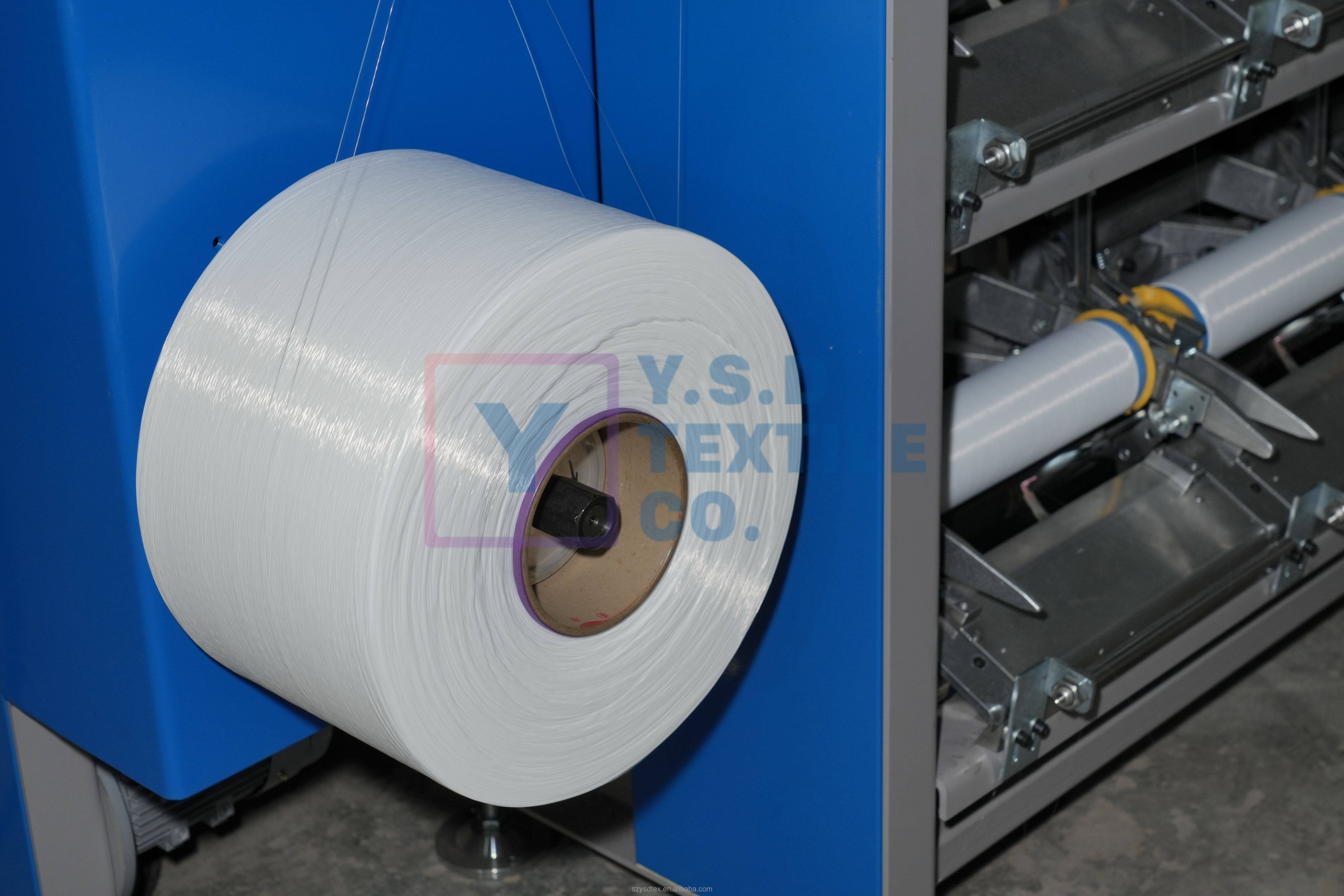

Mother yarn splitting machine rolling on paper bobbin

1. stable tension on each splitted bobbin from beginning to end

2. use normal DTY paper bobbin, low production cost and easy found

3. no weight limit on mother yarn size, 12kg -- 24kg can run

4. running speed 800-900 m/min

5. friction drum control each spindle, no need each splitted bobbin same size, according to your require decide each bobbin size during splitting

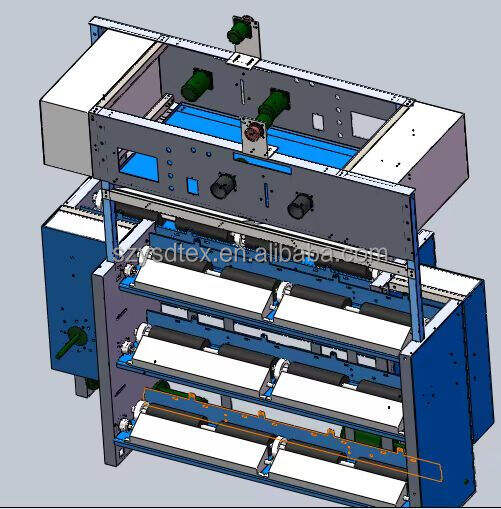

spindles |

height |

length |

width |

24 |

1900mm |

2000mm |

1000mm |

1. Spindles

One side 12 spindles, two sides total 24 spindles (separate control)

2. Paper bobbin size

Length 290mm, outsize 78mm, inner size 67mm and 56mm,

3. Stable tension

Friction drum keep each bobbin same tension

4. Export package

5 sets in 1*20GP11 sets in 1*40HQ

5. Split mother yarn

Nylon and polyester mono yarn with 10D-70D, within 12F

6. Easy control system

Delta motors, English control system

Suzhou YSD Textile Co., Ltd. is located in Pingwang Town, Yangtze River Delta, covers an area of 20000 square meters, mainly produces top grade high-speed mother yarn sectional split warping machine, mother yarn splitting machine, all kinds of women's fabrics, Wujiang Telong Chemical Fiber Co., Ltd. is located in Zhenze Town, covers an area of 20000 square meters, production of nylon/ polyester monofilament yarn, mother yarn, organza (textured) yarn, feather yarn 8000 tons each year, our third phases of spinning building has started construction, after the completion of the annual output can be above 20000 tons. We are based on the perspective of customers, to help you solve problems, grow together, mutual benefit and win-win.

1. How about production time? Each group of machine production time 40-50 days, 50 sets each group

2. How about payment term?

T/T 3/7 before delivery, LC at sight

3. How about production quantity?

Each 24 hours run 60KG of Nylon 240/12 mother yarn at each machine (two sides)

4. How about speed at machine?

Normally run 800-1000m/min

5. How about electric match?

Use Delta motor, running power about 2kw, start power 1.5kw

Welcome contact Rosie by whatsapp/ wechat/ phone: +86 152 6197 6205Email: rosie15261976205@163. com

EN

EN

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

RO

RO

RU

RU

ES

ES

ID

ID

UK

UK

VI

VI

TH

TH

TR

TR

BN

BN

NE

NE