New Sectional Nylon Polyester Mother Yarn Splitting Warping Machine Factory-Made Manufacturing Plants Core Motor

- Overview

- Inquiry

- Related Products

ProfixM

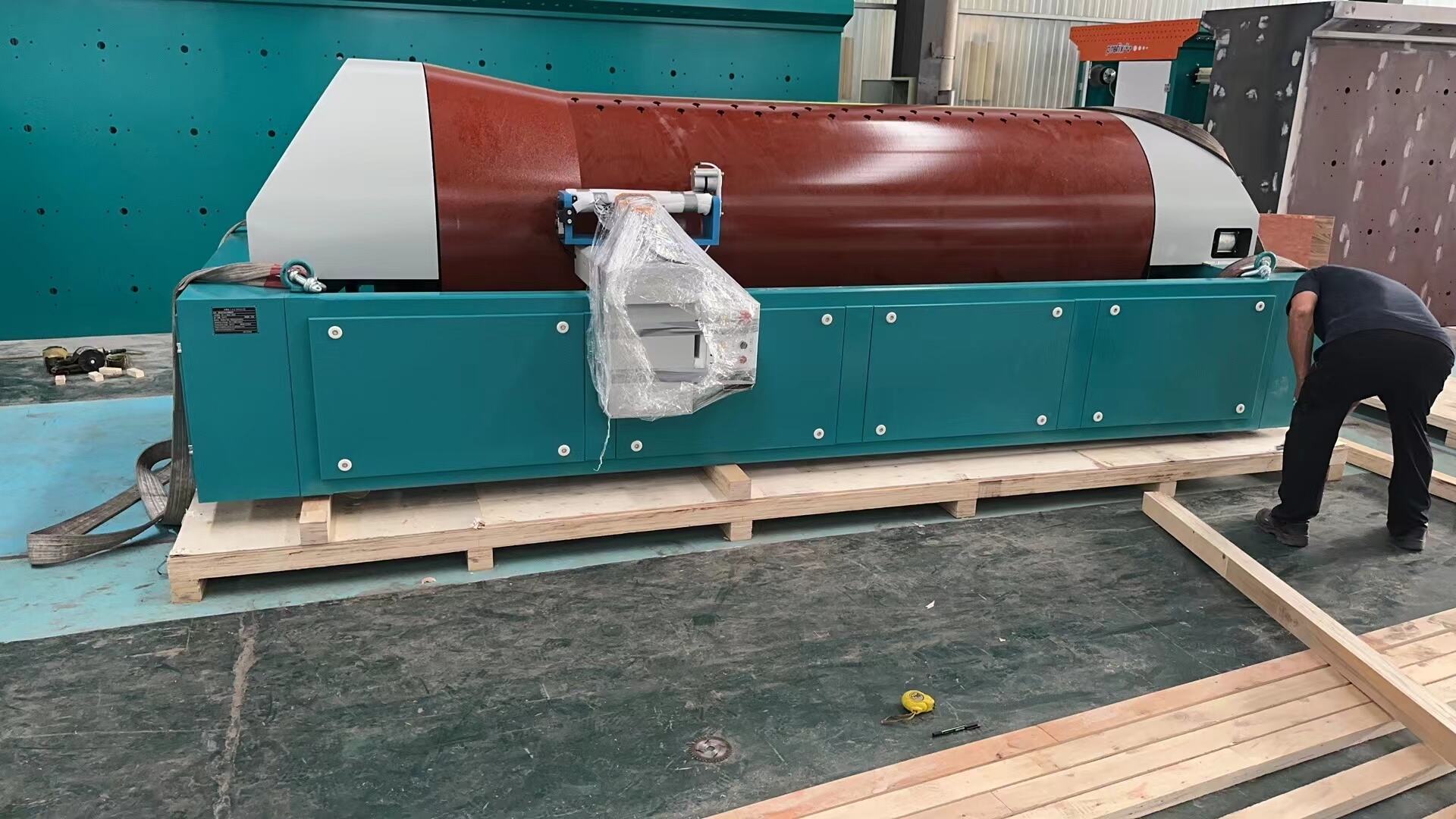

The New Sectional Nylon Polyester Mother Yarn Splitting Warping Machine is an advanced manufacturing tool that revolutionizes the textile industry. This machine is factory-made and is designed to cater to the specific requirements of textile factories and yarn manufacturing plants.

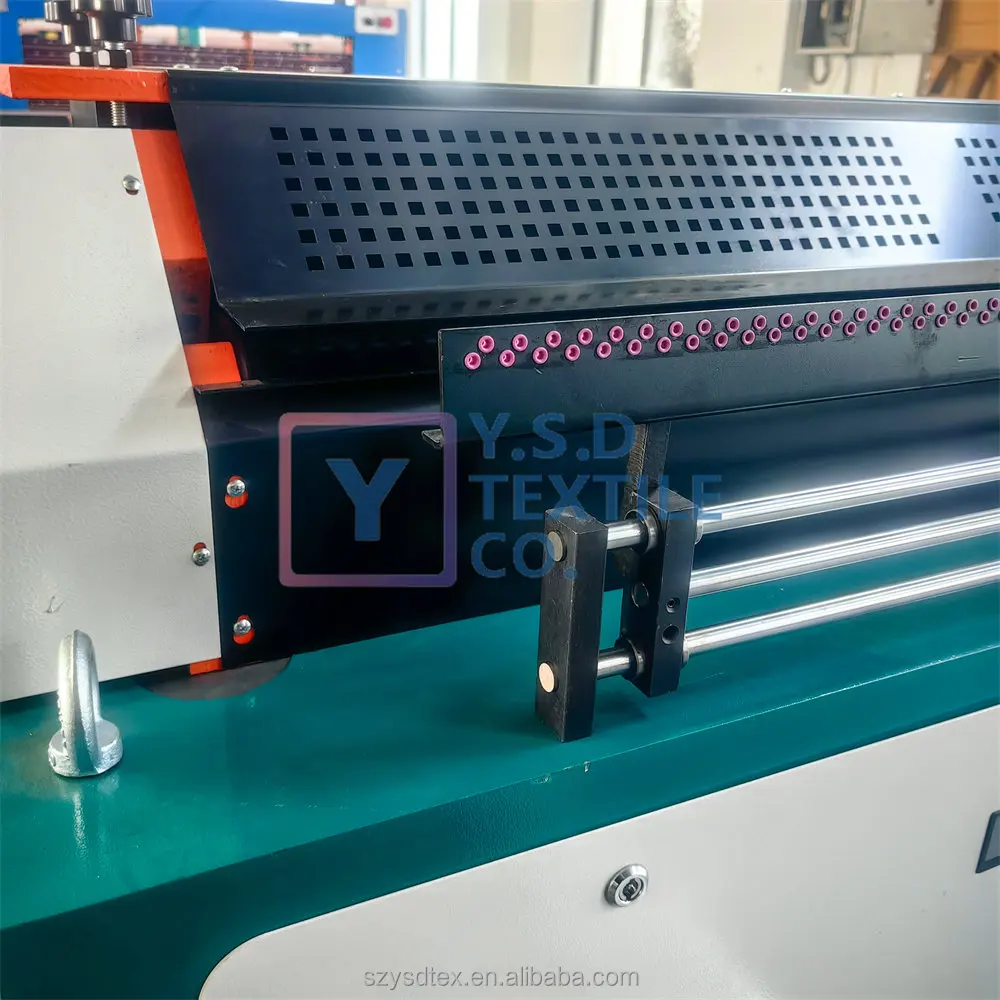

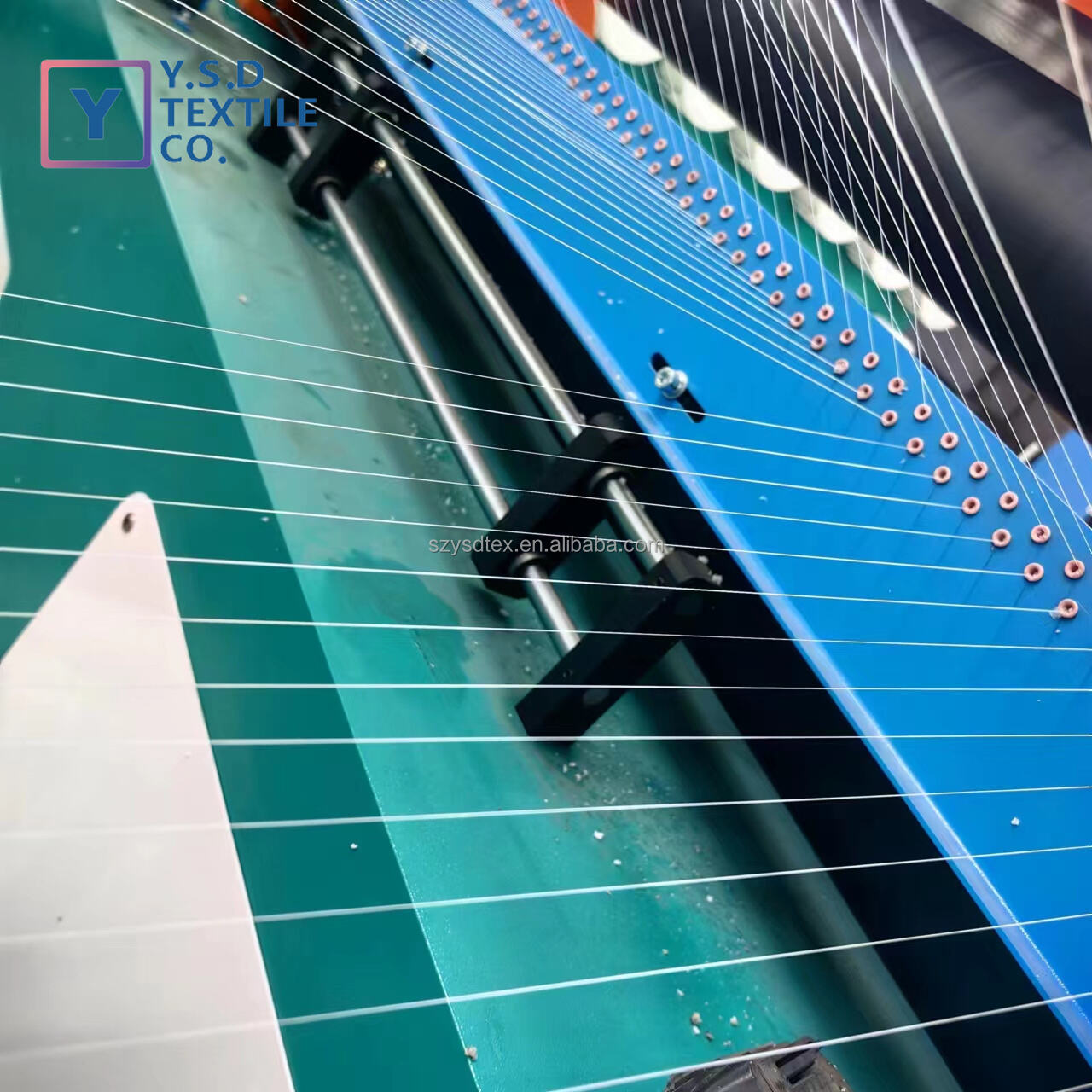

The machine features a core motor that is capable of providing high-speed production while maintaining the highest level of quality. The sectional design of the machine ensures that the warping process is performed with precision and efficiency. Nylon and Polyester materials can be processed with ease, making this machine suitable for a wide range of applications.

The Machine's splitting technology enhances the profixM efficiency of the process while ensuring maximum output of quality products. It makes use of a splitting unit that uses guillotine blades to divide yarns into the required split count. This guarantees that the yarn produced is of consistent quality and helps eliminate waste.

To ensure that the machine can handle heavy workloads, it features a durable structure. The machine's frame is made of high-quality materials that provide maximum stability and support. This design also helps reduce vibrations during operation, ensuring that the machine operates efficiently and quietly.

The machine is also easy to operate. It features an intuitive control panel that allows users to set the desired parameters for the production process. The machine also has a user-friendly interface that helps operators to switch easily between different warping settings.

The profixM New Sectional Nylon Polyester Mother Yarn Splitting Warping Machine is designed to improve production output and efficiency while maintaining high-quality standards. Its ability to work with different materials makes it an excellent choice for textile factories and other yarn manufacturing plants.

The machine's durability, precision, and easy-to-use features make it consistent with modern production systems, and it is an asset to any production facility. profixM has once again made a revolutionary product that is sure to increase the competitiveness of factories that utilize it. With the profixM New Sectional Nylon Polyester Mother Yarn Splitting Warping Machine, you can efficiently produce quality yarn that will satisfy customer requirements and meet your production needs for years to come.

item |

value |

||||||

Applicable Industries |

Manufacturing Plant |

||||||

Name |

SECTIONAL MOTHER YARN SPLITTING WARPING MACHINE |

||||||

Video outgoing-inspection |

Provided |

||||||

Machinery Test Report |

Provided |

||||||

Marketing Type |

New Product 2023 |

||||||

Warranty of core components |

1 Year |

||||||

Place of Origin |

China, Jiangsu |

||||||

Machine Type |

WARPING MACHINE |

||||||

Material Capabilities |

NYLON/ POLYESTER FDY/ DTY MOTHER YARN |

||||||

Condition |

New |

||||||

Weight (KG) |

17000 |

||||||

Yarn Usage |

1t/day 240D/12F SD |

||||||

Warping max speed |

600m/min ON 240/12 SD NYLON MOTHER YARN |

||||||

warping servo moto |

7.5kw |

||||||

beam moto |

15kw |

||||||

warp beam max speed |

180m/min |

||||||

displacement servo |

1.5kw |

||||||

Front roller servo |

5.5kw |

||||||

Back roller servo |

4.5kw |

||||||

EN

EN

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

RO

RO

RU

RU

ES

ES

ID

ID

UK

UK

VI

VI

TH

TH

TR

TR

BN

BN

NE

NE