PROFIX-M PF-4 Advanced Mother Yarn Warp Knitting Machine Most Advanced Splitting Section Cloth Cutting New Motor Included

- Overview

- Inquiry

- Related Products

PROFIX-M

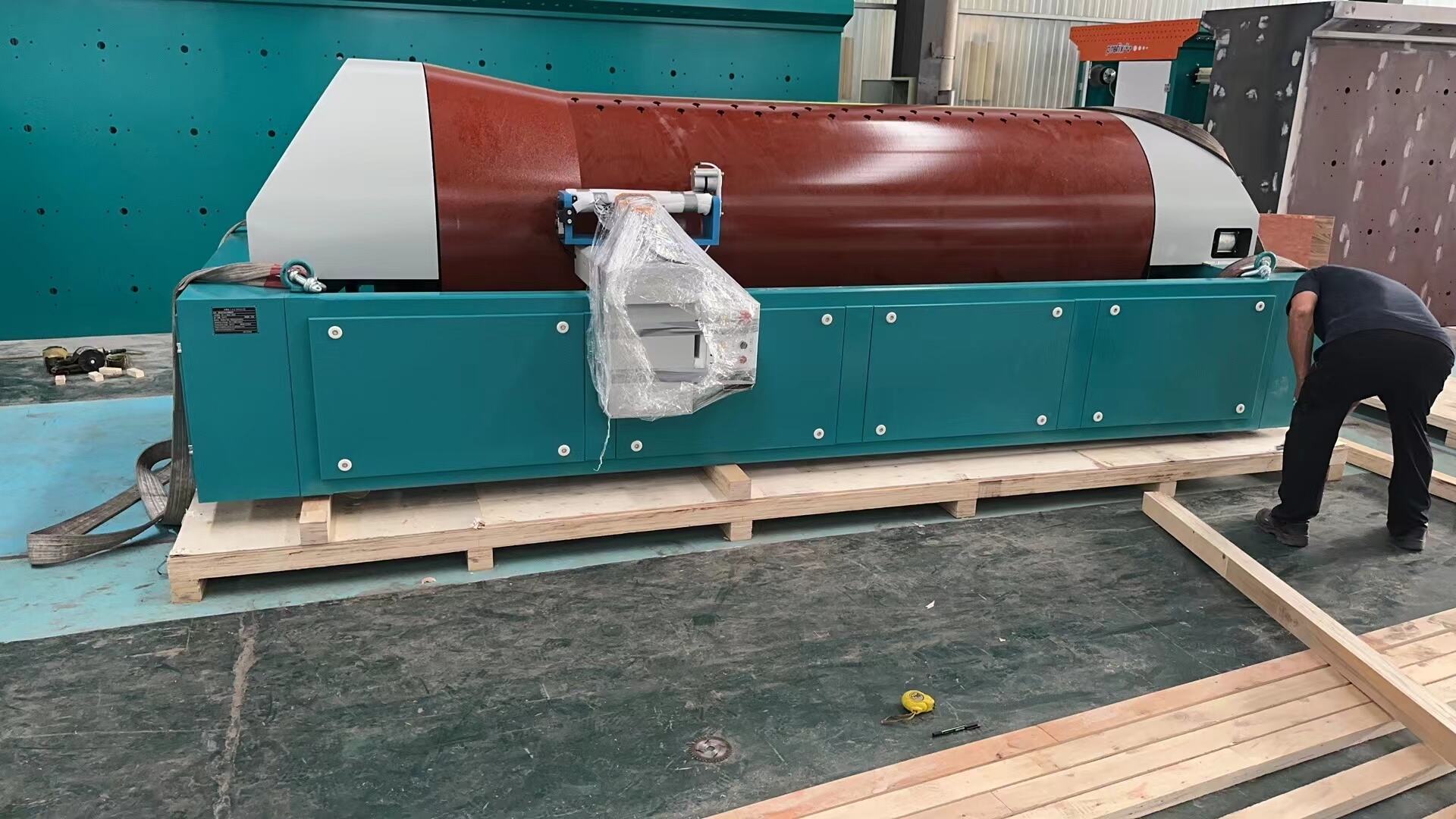

Introducing the PF-4 Advanced Mother Yarn Warp Knitting Machine - the latest innovation in textile machinery from PROFIX-M. This machine is designed to cater to the needs of textile manufacturers who require high quality, efficient and versatile knitting machines.

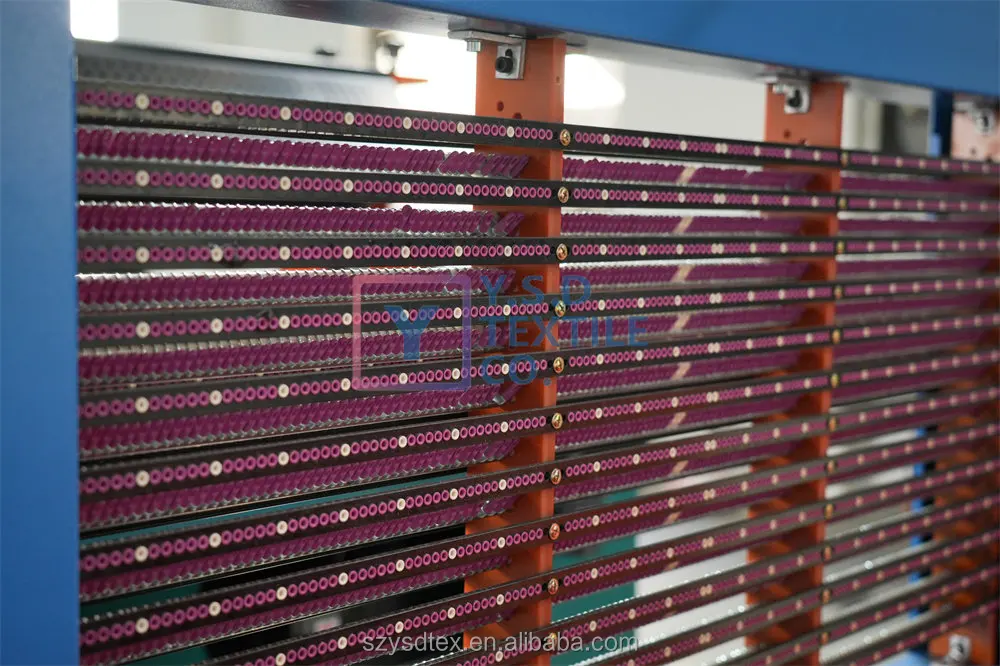

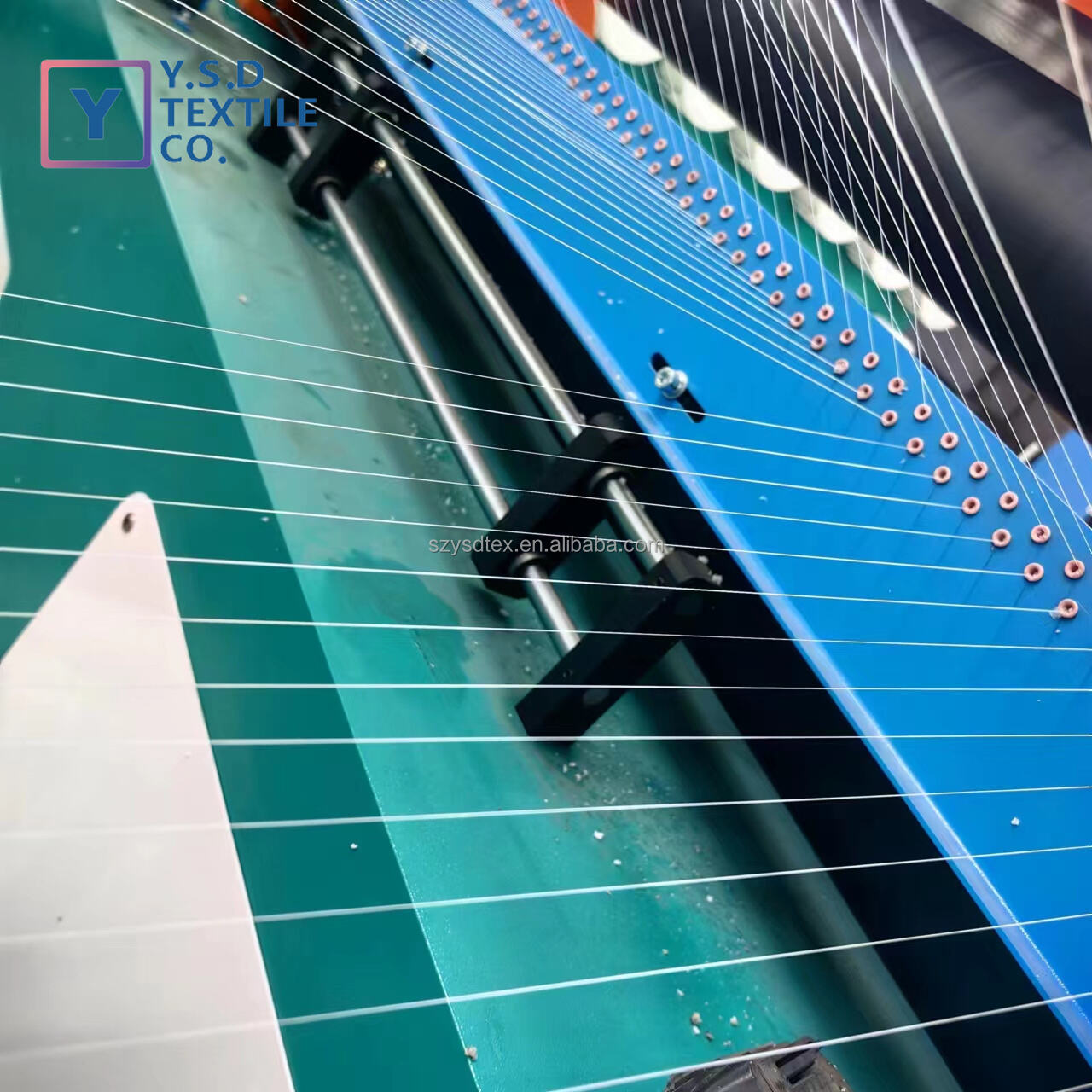

At the heart of the PF-4 machine is the advanced splitting section. This feature ensures that every single yarn is split perfectly, allowing for precise and consistent knitting. The result is a superior quality fabric that is durable, soft and comfortable to wear.

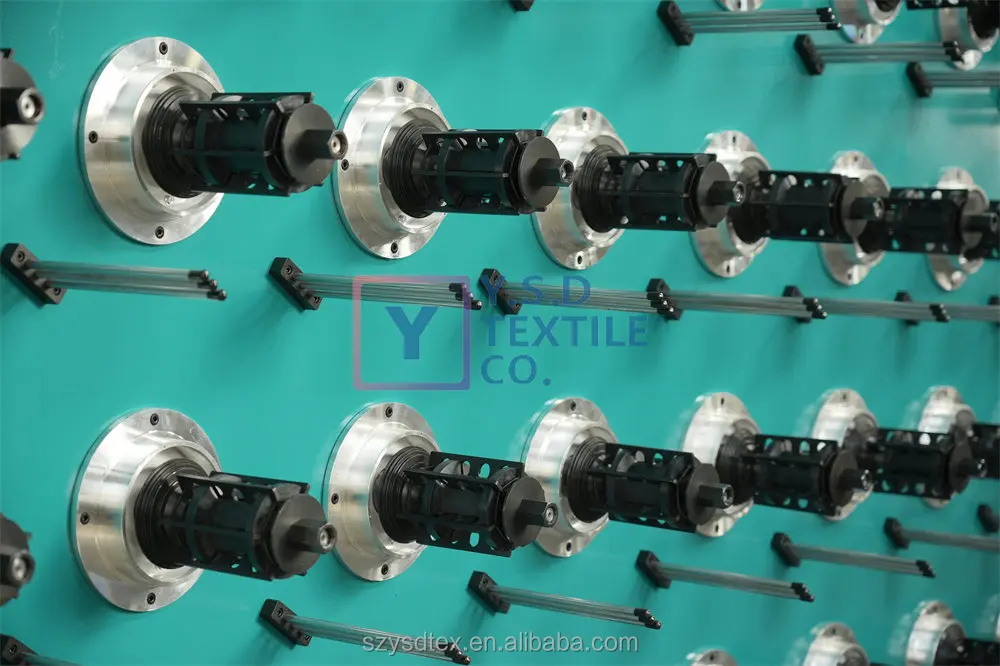

The new motor included in the profixM PF-4 machine further enhances its efficiency and performance. With its exceptional power, the motor ensures a smooth and steady operation, even when working with heavy fabrics or multiple layers of yarn. This means that you can knit faster and more efficiently without compromising on the quality of the finished product.

Moreover, the advanced mother yarn warp knitting machine has a cloth cutting feature that makes the process of cutting fabrics a breeze. With the latest cloth cutting technology integrated into the machine, you can say goodbye to the tedious and time-consuming manual fabric cutting process.

The PF-4 machine is designed to provide maximum flexibility to the user. Its versatile features allow for the knitting of various fabrics, including jerseys, ribbed fabrics, and interlocks, among others. This means that you can cater to the needs of different customers and expand your product range.

The machine is also user-friendly, with easy-to-understand controls and a simple interface. This makes it ideal for both experienced and novice operators. With a little bit of training, anyone can use the PROFIX-M PF-4 Advanced Mother Yarn Warp Knitting Machine with ease and produce top-quality fabrics.

If you're looking for a high-quality, efficient, and versatile knitting machine for your textile manufacturing business, look no further than the PROFIX-M PF-4 Advanced Mother Yarn Warp Knitting Machine. With its advanced features, efficient motor, and user-friendly interface, this machine is sure to increase the efficiency and productivity of your business while producing top-quality fabrics.

item |

value |

product |

MACHINE |

material capabilities |

NYLON/POLYESTER MOTHER YARN |

weight (kg) |

13500 |

machine type |

WARPING MACHINE |

video outgoing-inspection |

Provided |

machinery test report |

Provided |

core components |

Engine |

place of origin |

China |

Jiangsu |

|

warranty |

1 Year |

Name |

splitting and Striping warping machine mother yarn warping machine |

Usage |

1t/day 240D/12F SD |

Warping max speed |

600m/min |

mother yarn tension |

0-500cn |

warping servo moto |

7.5kw |

beam moto |

15kw |

warp beam max speed |

180m/min |

displacement servo |

1.5kw |

Front roller servo |

5.5kw |

Back roller servo |

4.5kw |

EN

EN

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

RO

RO

RU

RU

ES

ES

ID

ID

UK

UK

VI

VI

TH

TH

TR

TR

BN

BN

NE

NE