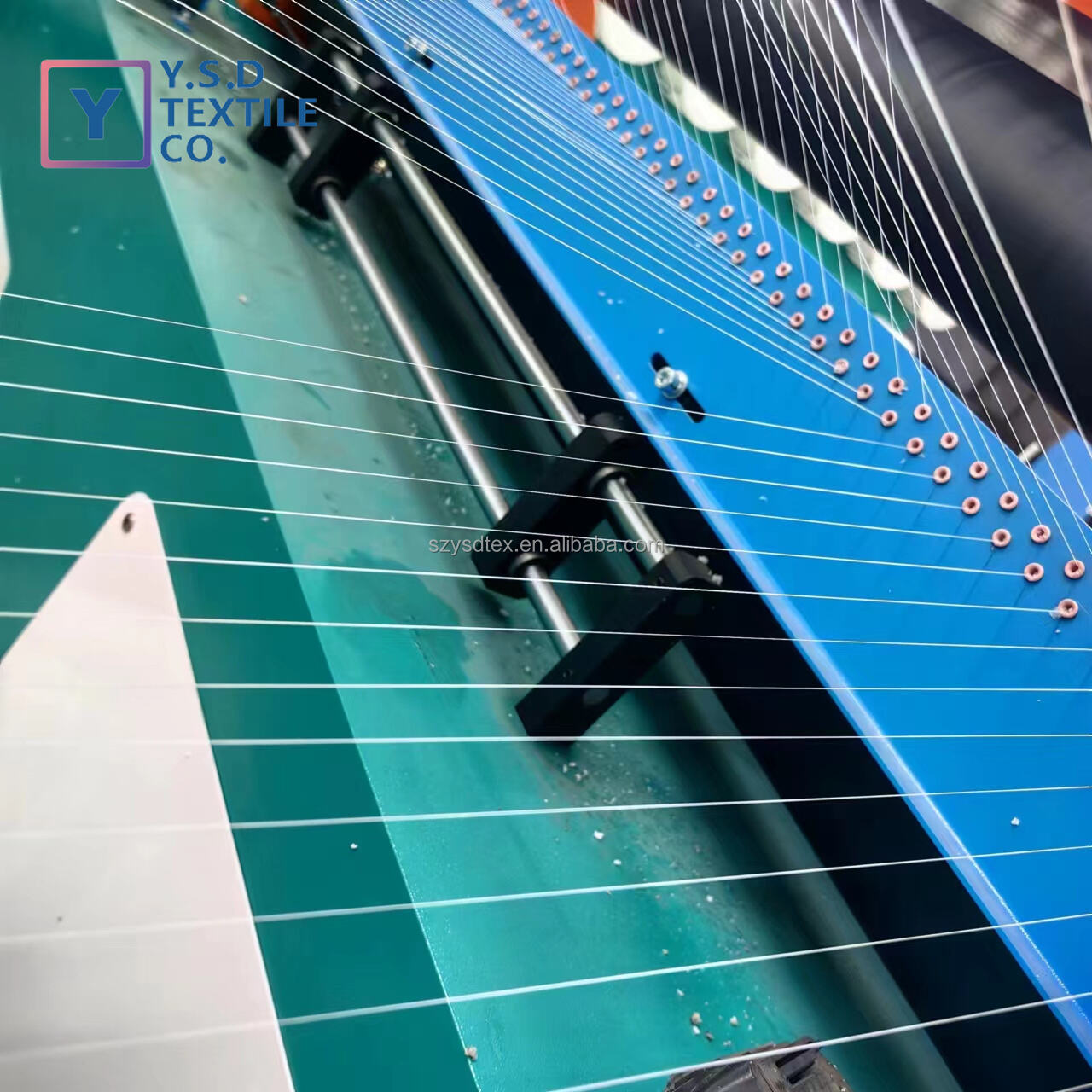

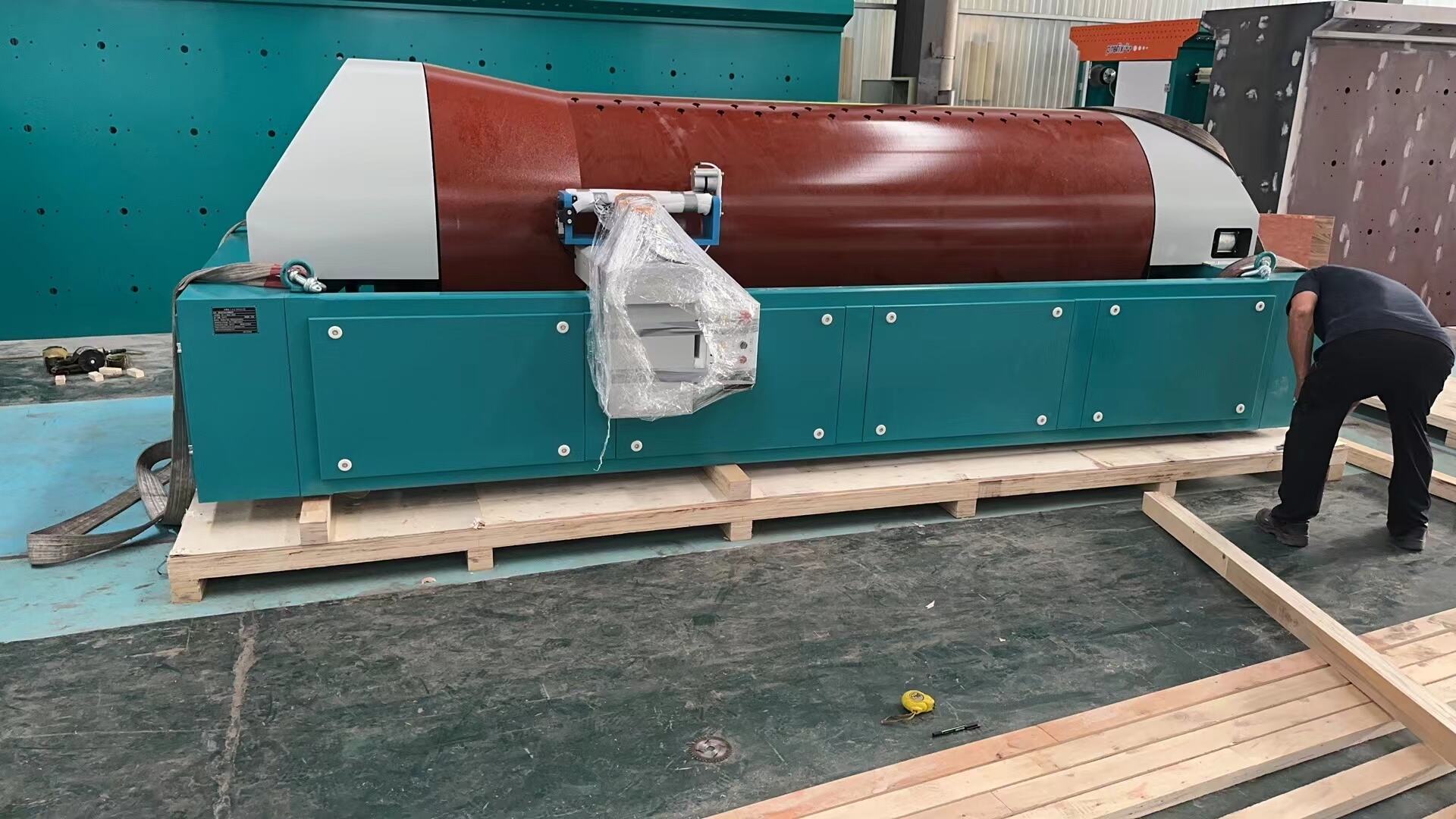

Splitting and Stripping Warping Machine Mother Yarn Loom Textile Machinery for Knitting for Manufacturing Plants

- Overview

- Inquiry

- Related Products

The profixM’s Splitting and Stripping Warping Machine Mother Yarn Loom Textile Machinery for Knitting is the ideal addition to any manufacturing plant that deals with textiles. This machine is designed to help businesses split and strip mother yarn with ease, making the entire process more efficient and productive. The profixM’s Splitting and Stripping Warping Machine is one of the most advanced machines on the market and is built to last.

The profixM’s Splitting and Stripping Warping Machine is designed for use in knitting manufacturing plants. Depending on the type of yarn being manufactured, the splitting and stripping process can prove to be quite a challenge for businesses. That's where the profixM’s Splitting and Stripping Warping Machine comes in. The machine is specifically designed to save time and increase efficiency by automating the process of splitting and stripping yarn. This means that businesses can save on time and labor costs while still producing high-quality yarn.

One of the key features of the profixM’s Splitting and Stripping Warping Machine is its ability to handle different types of yarn. Whether you are working with cotton, wool, or silk yarn, the profixM’s Splitting and Stripping Warping Machine can handle it all. This means that businesses that deal with a variety of yarn types can benefit from investing in this machine. The machine is also designed to handle varying yarn thicknesses and lengths, making it even more versatile.

The profixM’s Splitting and Stripping Warping Machine is also designed to be user-friendly. The machine is easy to operate and comes with a detailed instruction manual. This means that businesses can start using the machine as soon as it arrives without any extensive training or additional paperwork. The machine is also designed to be low-maintenance, which means that businesses can focus on other pressing matters in the plant while the machine takes care of the yarn splitting and stripping.

The profixM’s Splitting and Stripping Warping Machine is an excellent addition to any manufacturing plant that deals with textiles. With its advanced features, user-friendly design, and ability to handle different types of yarn, this machine is a must-have for any knitting manufacturer looking to improve their productivity and efficiency. So, why wait? Invest in the profixM’s Splitting and Stripping Warping Machine today and take the first step towards revolutionizing your manufacturing plant

item |

value |

product |

MACHINE |

material capabilities |

NYLON/POLYESTER MOTHER YARN |

weight (kg) |

17000 |

machine type |

WARPING MACHINE |

video outgoing-inspection |

Provided |

machinery test report |

Provided |

core components |

Engine |

Place of origin |

China |

Jiangsu |

|

warranty |

1 Year |

Name |

NYLON POLYAMIDE POLYESTER MOTHER YARN WARPING MACHINE |

Usage |

1t/day 240D/12F SD |

Warping max speed |

600m/min |

mother yarn tension |

0-500cn |

warping servo moto |

7.5kw |

beam moto |

15kw |

warp beam max speed |

250m/min |

displacement servo |

1.5kw |

Front roller servo |

5.5kw |

Back roller servo |

4.5kw |

1) The warping machine has the characteristics of high efficiency, stability, and reliability, which can greatly improve the production efficiency of the textile industry.

2) Its high precision and consistency ensure the quality of the fabric, making it more neat and uniform.

3) The warping machine is widely used in the textile industry and is one of the very important production equipment in textile factories

Q:How to place machines order

A:Please send us your purchase order by email, whatsapp or wechat. We need to know the following information for your order:

(1) Your products width and thickness(webbing, tapes, lace width and thickness)

(2) Price Item, Destination Port, Delivery time required

(3) Shipping information: Company Name, Address, Phone Number, Destination Seaport/Airport

Q:What are the payment terms

A:For orders, we can accept T/T, L/C at sight

Q:How many years of producing these machine

---We produced these machine for more than 15 years

EN

EN

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

RO

RO

RU

RU

ES

ES

ID

ID

UK

UK

VI

VI

TH

TH

TR

TR

BN

BN

NE

NE