Top Grade Mother Yarn Warping Machine New Braiding Machine with Motor Sectional Split for Manufacturing Plant Textile

- Overview

- Inquiry

- Related Products

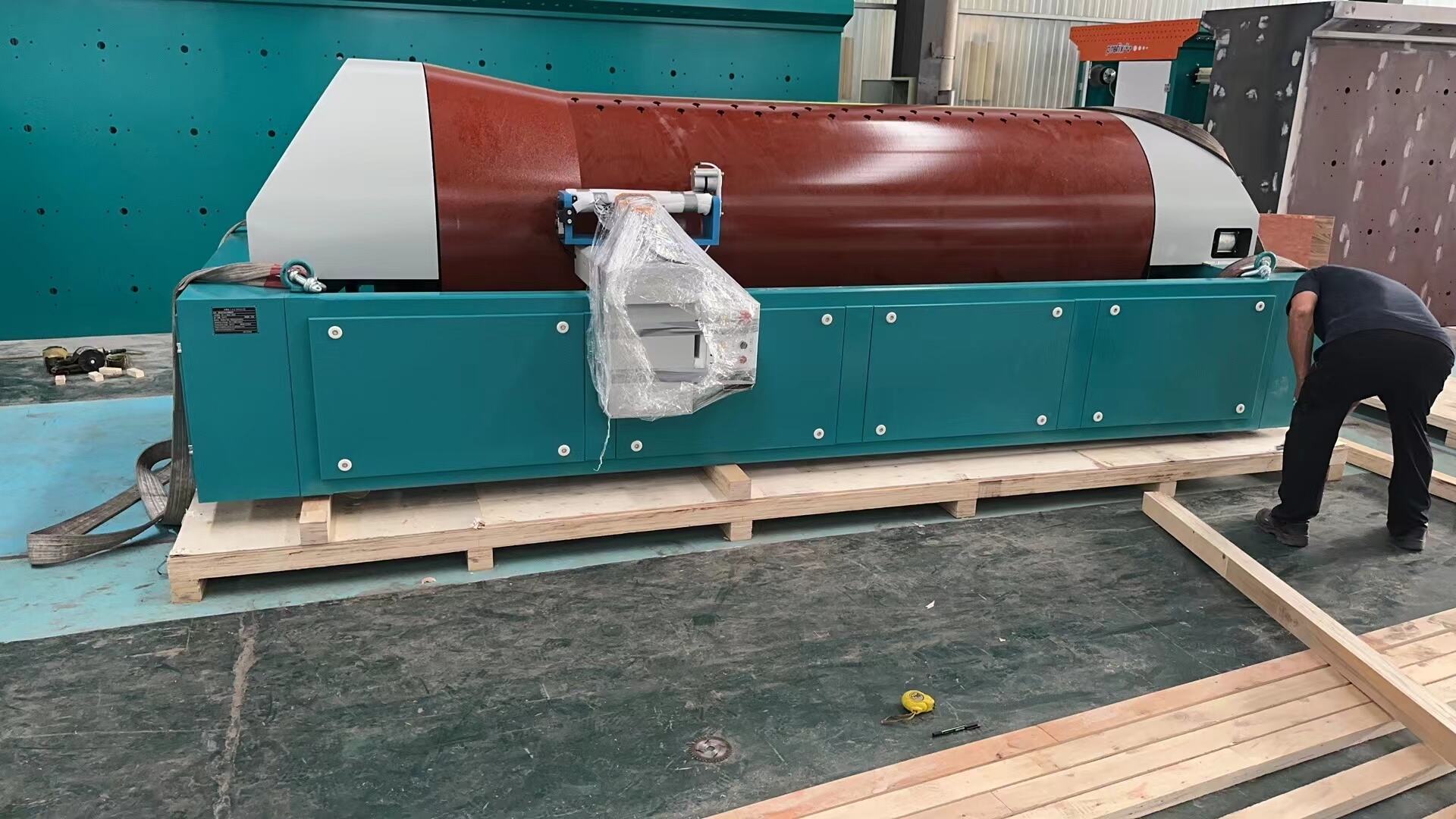

If you're in the market for a high-quality yarn warping machine or braiding machine, allow us to introduce you to the Top Grade Mother Yarn Warping Machine New Braiding Machine with Motor Sectional Split, proudly produced by the trusted brand profixM. Designed for manufacturing plant textiles, this machine is the perfect addition to any textile production facility.

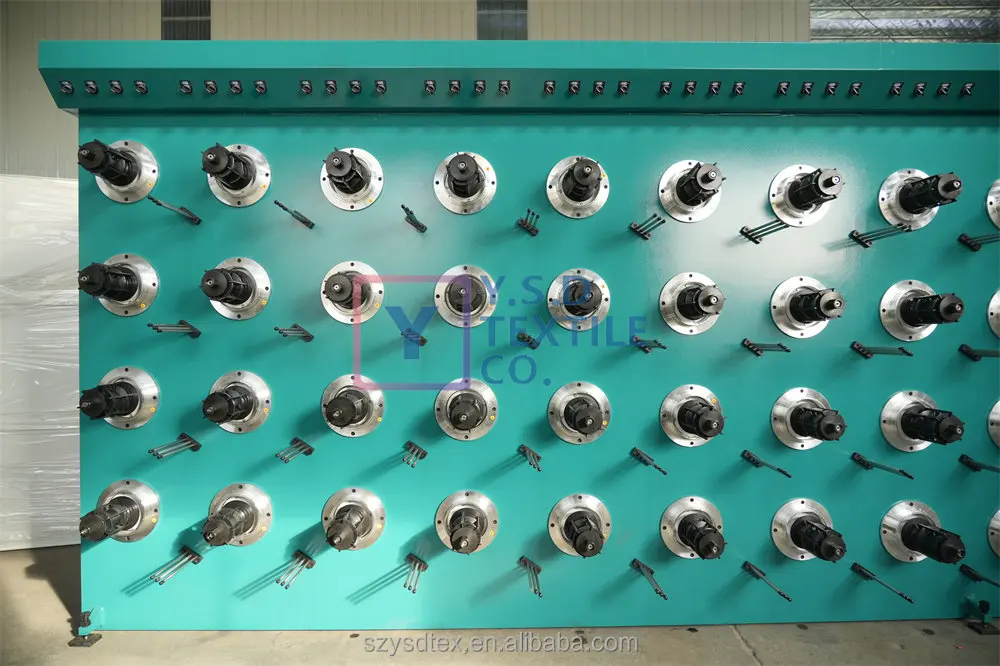

One of the standout features of this machine is its motor sectional split. This allows for precise control over each section of the machine, resulting in a more accurate and consistent production process. Plus, the use of a motor ensures the machine operates efficiently, saving time and minimizing downtime.

Another great feature of the Top Grade Mother Yarn Warping Machine New Braiding Machine is its ease of use. With common language labeling and a simple interface, the machine can be operated by anyone with minimal training. No need to worry about complex machinery or specialized knowledge - the profixM’s machine is designed to be user-friendly and accessible.

In terms of performance, this machine does not disappoint. It boasts a high warp tension and a maximum warp count of up to 3200, making it suitable for a wide range of textile materials and production applications. Additionally, the machine is built to last - its sturdy construction and durable components ensure a long lifespan and low maintenance requirements.

The Top Grade Mother Yarn Warping Machine New Braiding Machine with Motor Sectional Split is an excellent investment for any textile manufacturing facility. Its combination of precision, efficiency, and durability make it a top-performing machine that will streamline your production process and contribute to your bottom line. And with profixM's reputation for quality and reliability, you can trust that your investment will pay off for years to come

item |

value |

product |

Other |

material capabilities |

Yarn |

Weight (kg) |

15000 |

machine type |

Braiding Machine |

Video outgoing-inspection |

Provided |

machinery test report |

Provided |

core components |

MOTOR, engine |

Place of origin |

China |

Jiangsu |

|

warranty |

1 Year |

Applicable Industries |

Manufacturing Plant |

Showroom Location |

None |

Warranty of core components |

1 Year |

Condition |

New |

Marketing Type |

New Product 2024Model Number: New Product 2023 |

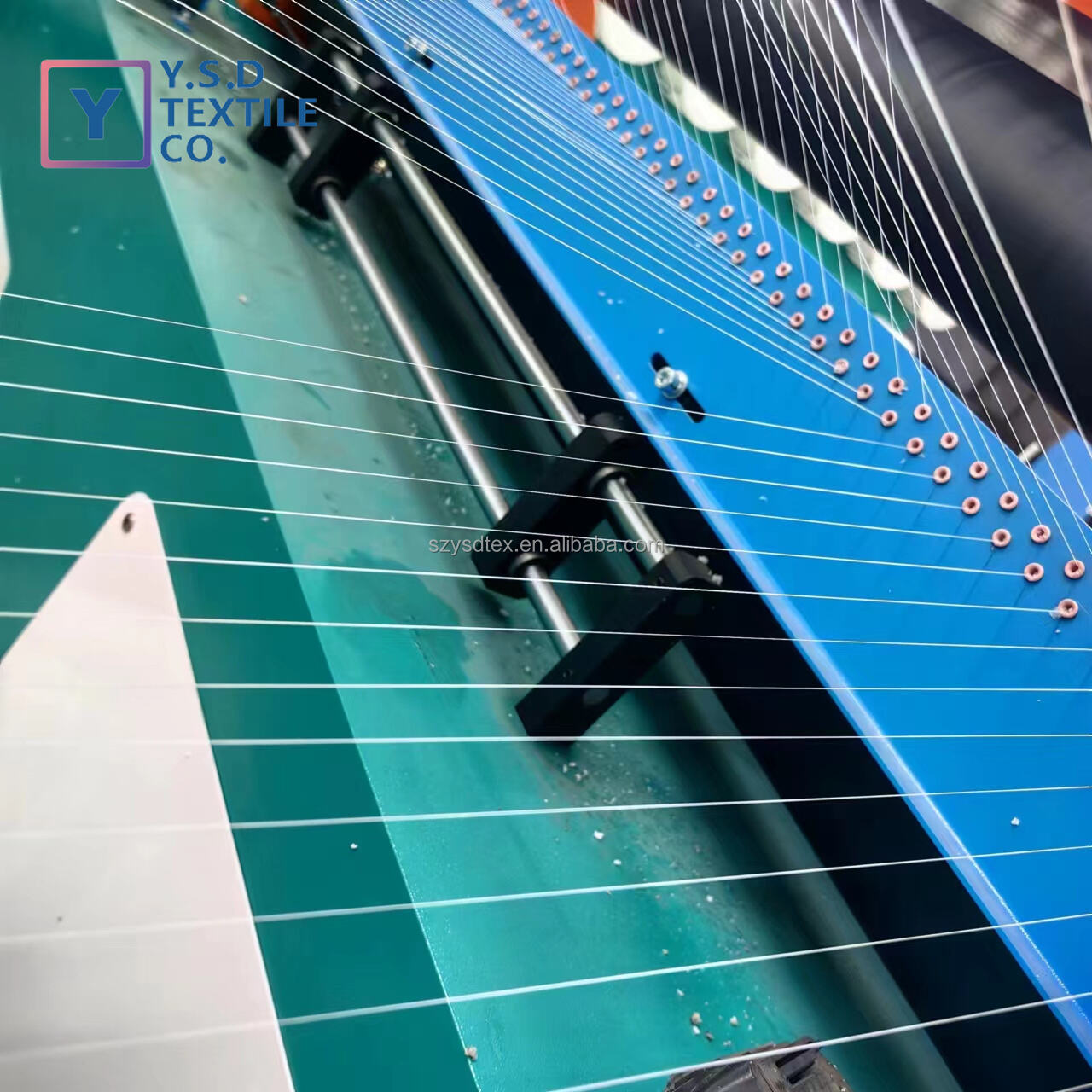

1) The warping machine has the characteristics of high efficiency, stability, and reliability, which can greatly improve the production efficiency of the textile industry.

2) Its high precision and consistency ensure the quality of the fabric, making it more neat and uniform.

3) The warping machine is widely used in the textile industry and is one of the very important production equipment in textile factories

Q:How to place machines order

A:Please send us your purchase order by email, whatsapp or wechat. We need to know the following information for your order:

(1) Your products width and thickness(webbing, tapes, lace width and thickness)

(2) Price Item, Destination Port, Delivery time required

(3) Shipping information: Company Name, Address, Phone Number, Destination Seaport/Airport

Q:What are the payment terms

A: For orders, we can accept T/T, L/C at sight

Q:How many years of producing these machine

---We produced these machine for more than 15 years

EN

EN

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

RO

RO

RU

RU

ES

ES

ID

ID

UK

UK

VI

VI

TH

TH

TR

TR

BN

BN

NE

NE