Yarn Creel Mother Warping Machine Knitting Weaving Loom Sectional Warping for Manufacturing Plant

- Overview

- Inquiry

- Related Products

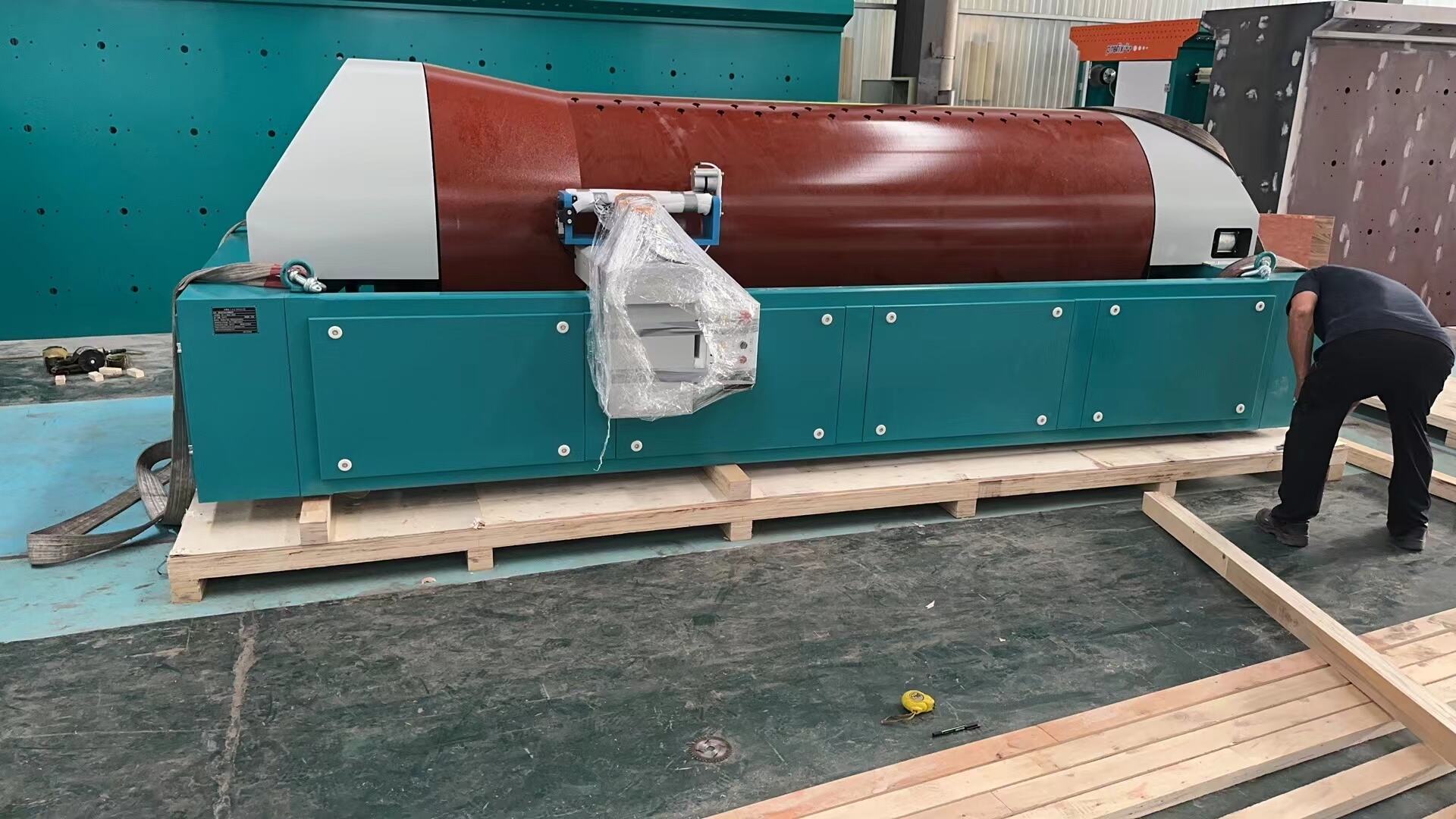

ProfixM's Yarn Creel Mother Warping Machine is designed to provide a steadfast solution for efficient manufacturing processes in the textile industry. The machine consists of a creel mother, a warping machine, and a sectional warping mechanism, all integrated together to provide an ideal manufacturing experience.

Designed with durable precision, this knitting and weaving loom machine is perfect for high-volume weaving applications. Whether you're in the business of creating heavy textiles like curtains and upholstery, or you specialize in light fabrics like clothing and bed linens, the Yarn Creel Mother Warping Machine is a reliable and cost-effective solution to your weaving requirements.

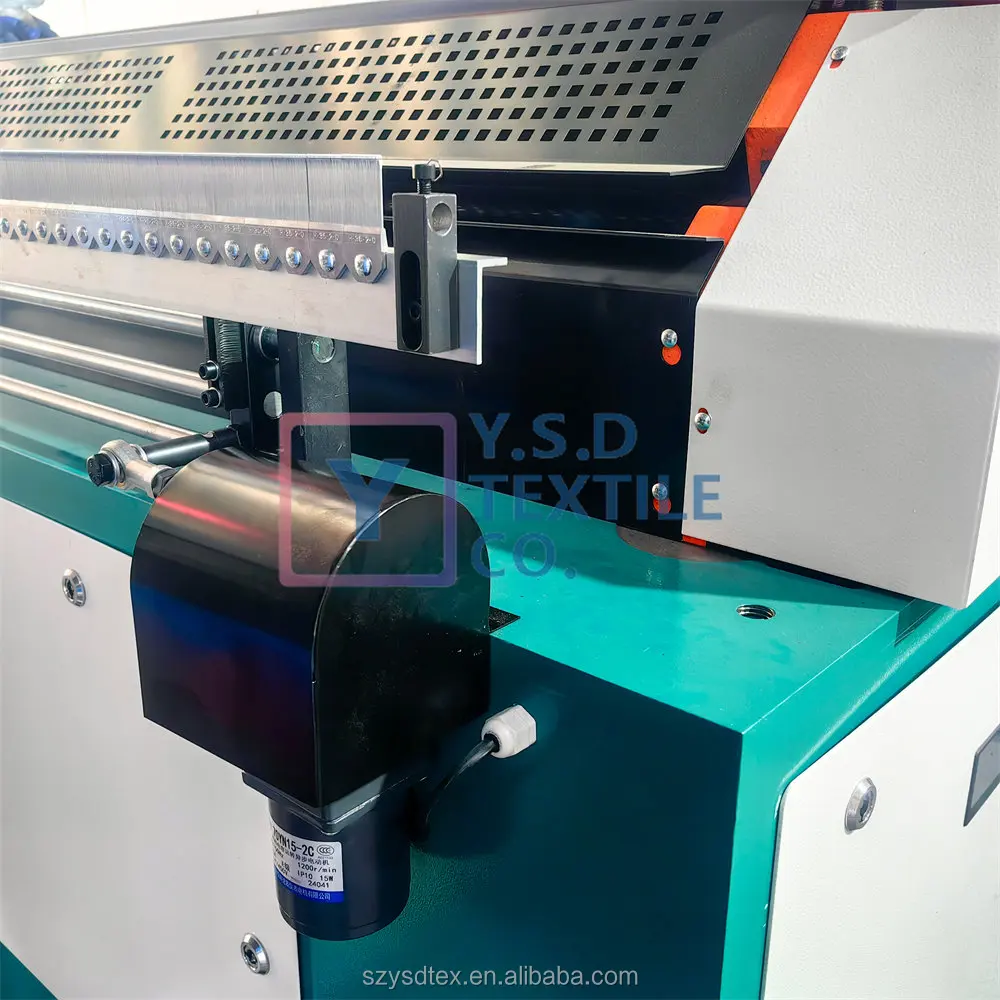

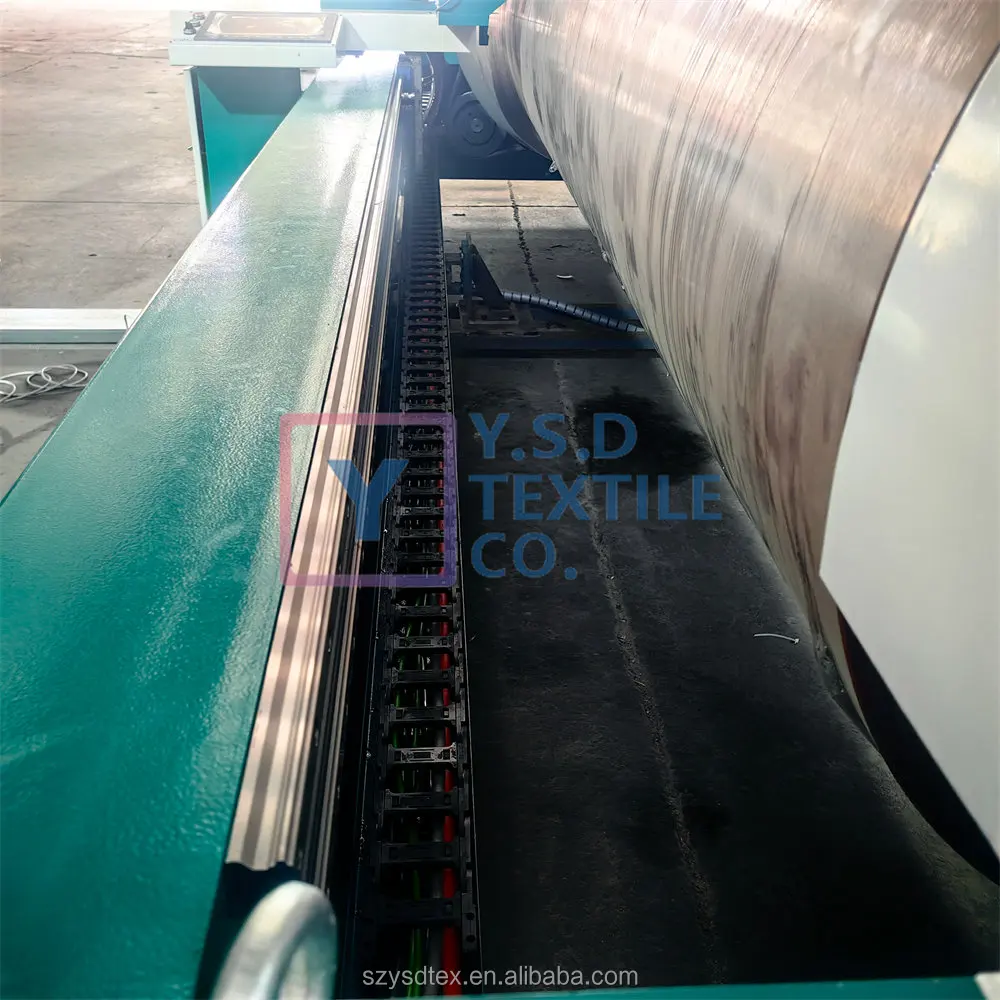

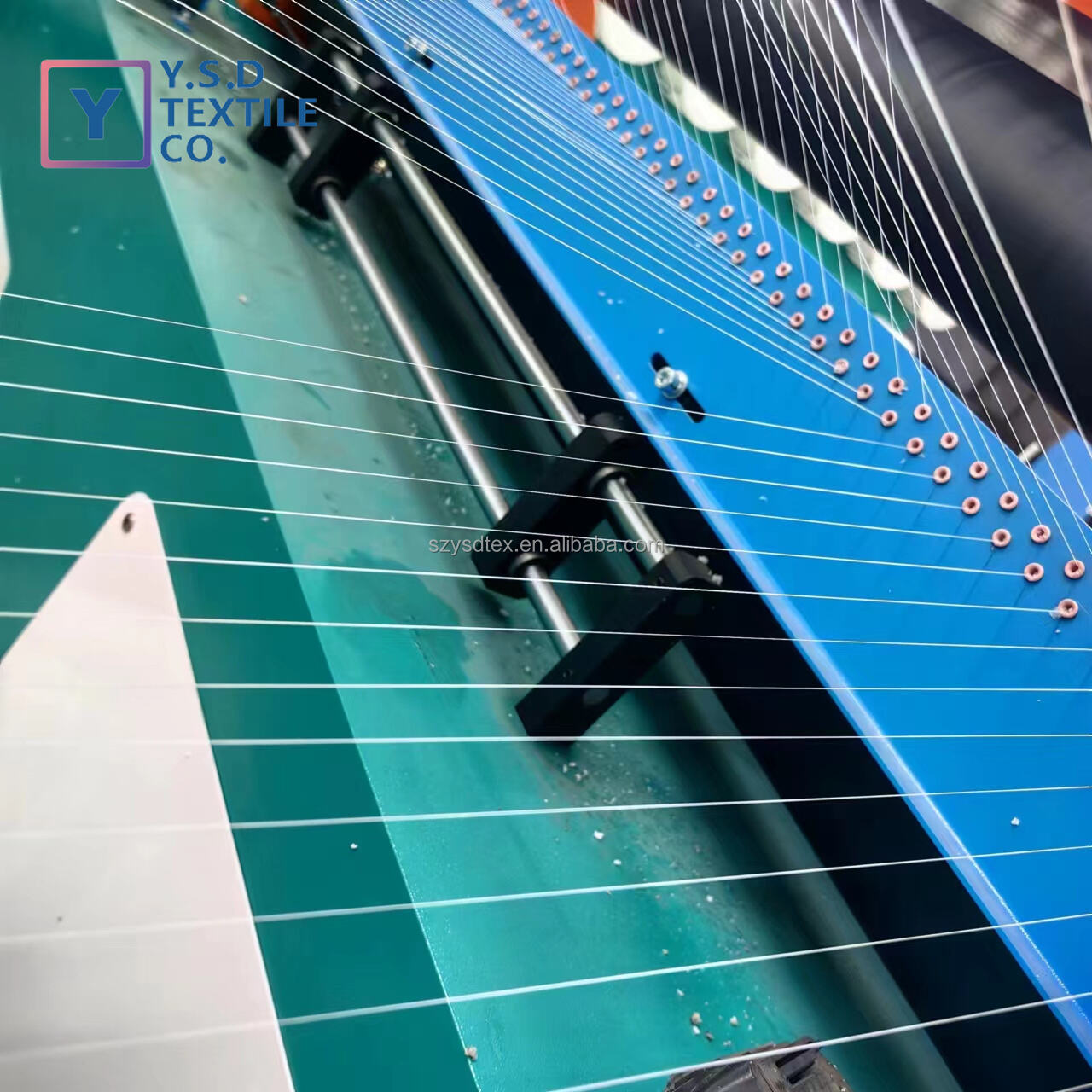

The heart of the machine is a creel mother, responsible for holding the yarn at a constant tension, ensuring that it is woven faultlessly. The creel mother is specifically designed to create a smooth and continuous flow of yarn without any breaks or interruptions, promoting uniformity in the final textile production. The warping machine comes equipped with a sectional warping system that allows for efficient processing of large batches of yarn at once, which ultimately reduces production time.

Furthermore, the machine is designed with an easy-to-use operating system, which can be easily operated by a single person. The efficient and streamlined design of the Yarn Creel Mother Warping Machine allows for ease and speed in shifting between different types of yarns, which is crucial for managing a variety of threads in a single manufacturing plant.

The Yarn Creel Mother Warping Machine is also built to last. The machine is made of high-quality materials, ensuring its longevity, reliability, and durability. Materials such as steel are used for the frame, while the individual parts are precision engineered. This machine has been put through rigorous testing and quality control measures to ensure the best possible performance for your textile manufacturing plant.

ProfixM's Yarn Creel Mother Warping Machine is a quality and reliable product that provides an efficient manufacturing solution for businesses in the textile industry. Whether you're looking for speed, reliability, or precision, this machine is the ideal choice for your plant's weaving and knitting operation. So, improve your weaving process and overall production with the trusted brand: ProfixM

item |

value |

product |

MACHINE |

material capabilities |

NYLON/POLYESTER MOTHER YARN |

Weight (kg) |

17000 |

machine type |

WARPING MACHINE |

Video outgoing-inspection |

Provided |

machinery test report |

Provided |

core components |

Engine |

place of origin |

China |

Jiangsu |

|

warranty |

1 Year |

Name |

sectional warping machine |

Usage |

1t/day 240D/12F SD |

Warping max speed |

600m/min |

mother yarn tension |

0-500cn |

warping servo moto |

7.5kw |

beam moto |

15kw |

warp beam max speed |

250m/min |

displacement servo |

1.5kw |

Front roller servo |

5.5kw |

Back roller servo |

4.5kw |

1) The warping machine has the characteristics of high efficiency, stability, and reliability, which can greatly improve the production efficiency of the textile industry.

2) Its high precision and consistency ensure the quality of the fabric, making it more neat and uniform.

3) The warping machine is widely used in the textile industry and is one of the very important production equipment in textile factories

Q:How to place machines order

A:Please send us your purchase order by email, whatsapp or wechat. We need to know the following information for your order:

(1) Your products width and thickness(webbing, tapes, lace width and thickness)

(2) Price Item, Destination Port, Delivery time required

(3) Shipping information: Company Name, Address, Phone Number, Destination Seaport/Airport

Q:What are the payment terms

A:For orders, we can accept T/T, L/C at sight

Q:How many years of producing these machine

---We produced these machine for more than 15 years

EN

EN

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

RO

RO

RU

RU

ES

ES

ID

ID

UK

UK

VI

VI

TH

TH

TR

TR

BN

BN

NE

NE