YSD CO Sectional Split Mother Yarn Warping Machine with Motor New Braiding Textile Machine for Manufacturing Plant

- Overview

- Inquiry

- Related Products

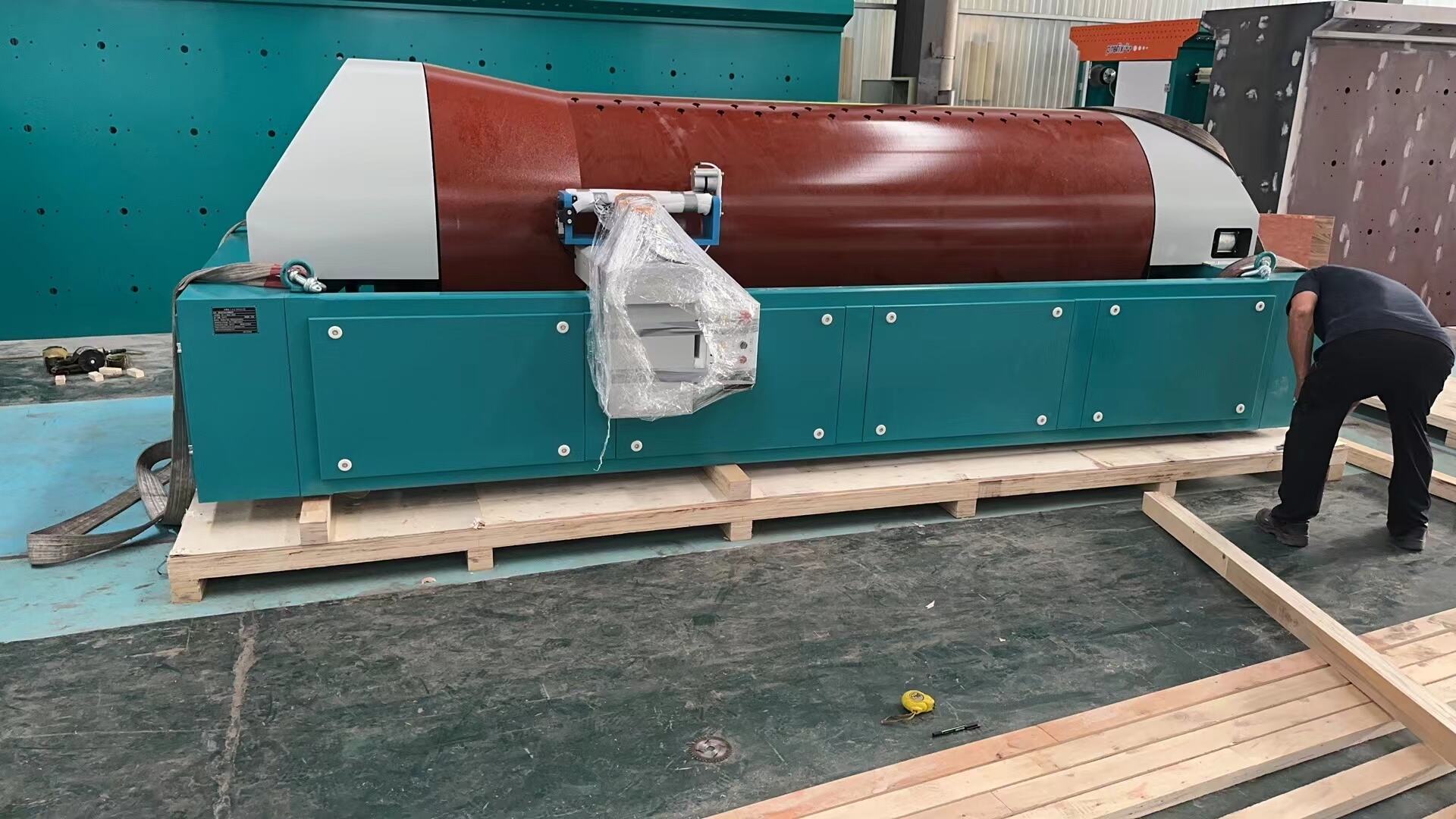

The profixM’s YSD CO Sectional Split Mother Yarn Warping Machine with Motor New Braiding Textile Machine is an essential piece of equipment for any manufacturing plant that specializes in textile production. With its high-quality design and advanced features, this machine is the perfect solution for manufacturing plants seeking to increase productivity and efficiency.

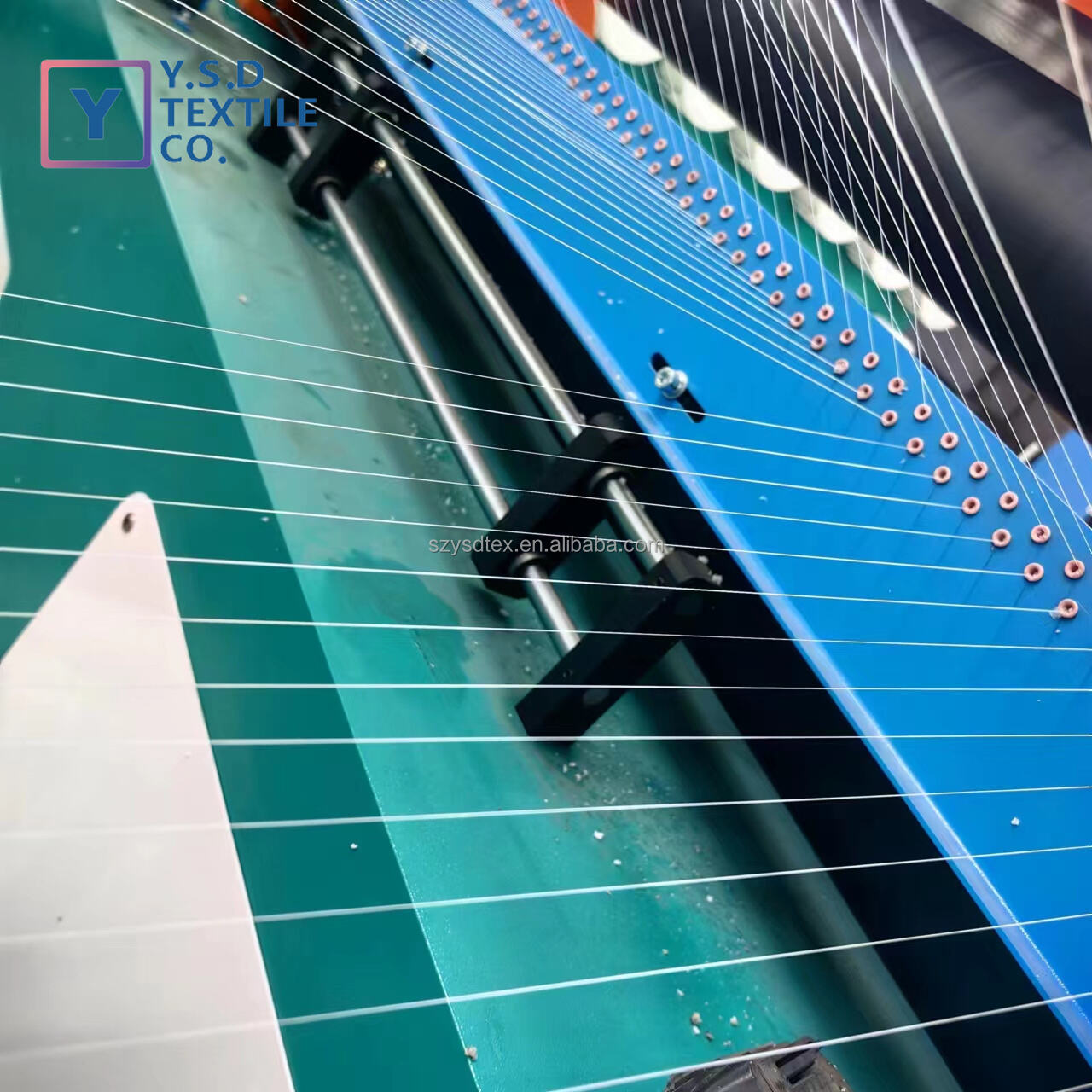

One of the standout features of the YSD CO Sectional Split Mother Yarn Warping Machine is its motorized design, which ensures smooth and precise operation. The machine features a powerful motor that offers unmatched speed and accuracy, making it easy to produce high-quality textile products with ease.

The machine also features a sectional design, which enables users to divide the yarn into different sections for easy handling and management. This feature makes it easy to produce large quantities of textile products quickly and efficiently, without compromising quality.

The YSD CO Sectional Split Mother Yarn Warping Machine is also designed with durability in mind. It is made with high-quality materials that are designed to withstand the rigors of frequent use and the harsh conditions of manufacturing environments. This ensures that the machine will last for many years, providing reliable service and excellent performance throughout its lifespan.

Additionally, the machine is easy to operate, which makes it an ideal choice for manufacturing plants of all sizes. It comes with clear instructions that are easy to follow, and the machine has intuitive controls that make it easy to operate. This means that even inexperienced users can quickly learn how to use the machine and start producing high-quality textile products in no time.

The profixM’s YSD CO Sectional Split Mother Yarn Warping Machine with Motor New Braiding Textile Machine is an essential piece of equipment for any manufacturing plant that specializes in textile production. It is reliable, durable, and easy to operate, and it offers advanced features that make it easy to produce high-quality textile products quickly and efficiently. So, if you're looking for a reliable and efficient textile manufacturing machine that delivers exceptional results, choose profixM’s YSD CO Sectional Split Mother Yarn Warping Machine with Motor New Braiding Textile Machine

item |

value |

product |

Other |

material capabilities |

Yarn |

Weight (kg) |

15000 |

machine type |

Braiding Machine |

Video outgoing-inspection |

Provided |

machinery test report |

Provided |

core components |

MOTOR, engine |

Place of origin |

China |

Jiangsu |

|

warranty |

1 Year |

Applicable Industries |

Manufacturing Plant |

Showroom Location |

None |

Warranty of core components |

1 Year |

Condition |

New |

Marketing Type |

New Product 2024Model Number: New Product 2023 |

1) The warping machine has the characteristics of high efficiency, stability, and reliability, which can greatly improve the production efficiency of the textile industry.

2) Its high precision and consistency ensure the quality of the fabric, making it more neat and uniform.

3) The warping machine is widely used in the textile industry and is one of the very important production equipment in textile factories

Q:How to place machines order

A:Please send us your purchase order by email, whatsapp or wechat. We need to know the following information for your order:

(1) Your products width and thickness(webbing, tapes, lace width and thickness)

(2) Price Item, Destination Port, Delivery time required

(3) Shipping information: Company Name, Address, Phone Number, Destination Seaport/Airport

Q:What are the payment terms

A:For orders, we can accept T/T, L/C at sight

Q:How many years of producing these machine

---We produced these machine for more than 15 years

EN

EN

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

RO

RO

RU

RU

ES

ES

ID

ID

UK

UK

VI

VI

TH

TH

TR

TR

BN

BN

NE

NE