YSD-M Mother Yarn Warping Knitting Machine Cloth Cutting Machine with Splitting Warp Feature for Manufacturing Plant

- Overview

- Inquiry

- Related Products

Introducing, the YSD-M Mother Yarn Warping Knitting Machine Cloth Cutting Machine with Splitting Warp Feature by ProfixM, the perfect solution for manufacturing plants looking for an efficient and durable machine to produce high-quality textiles.

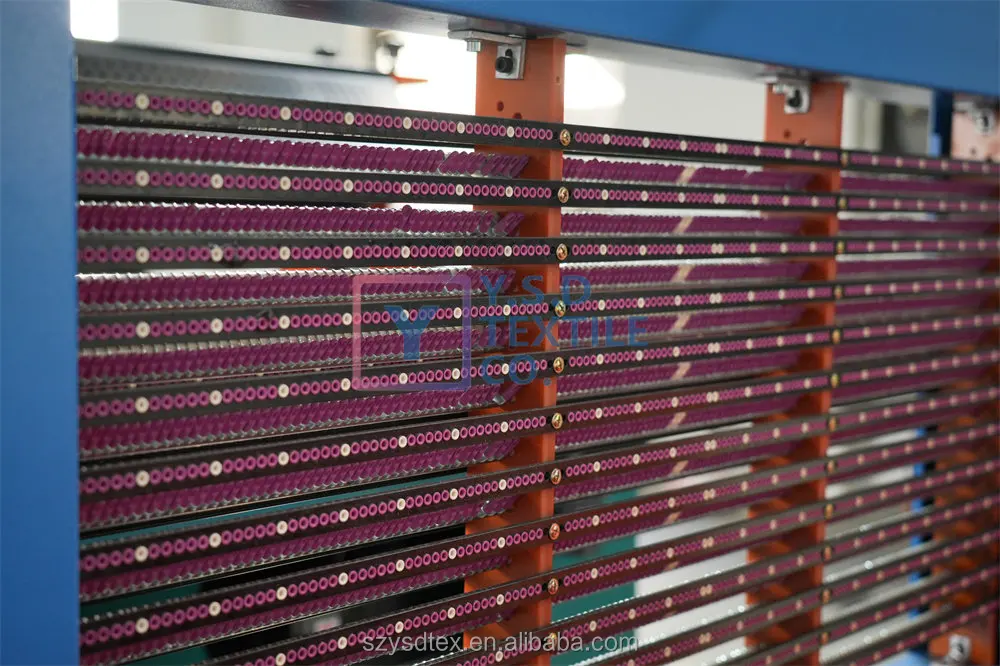

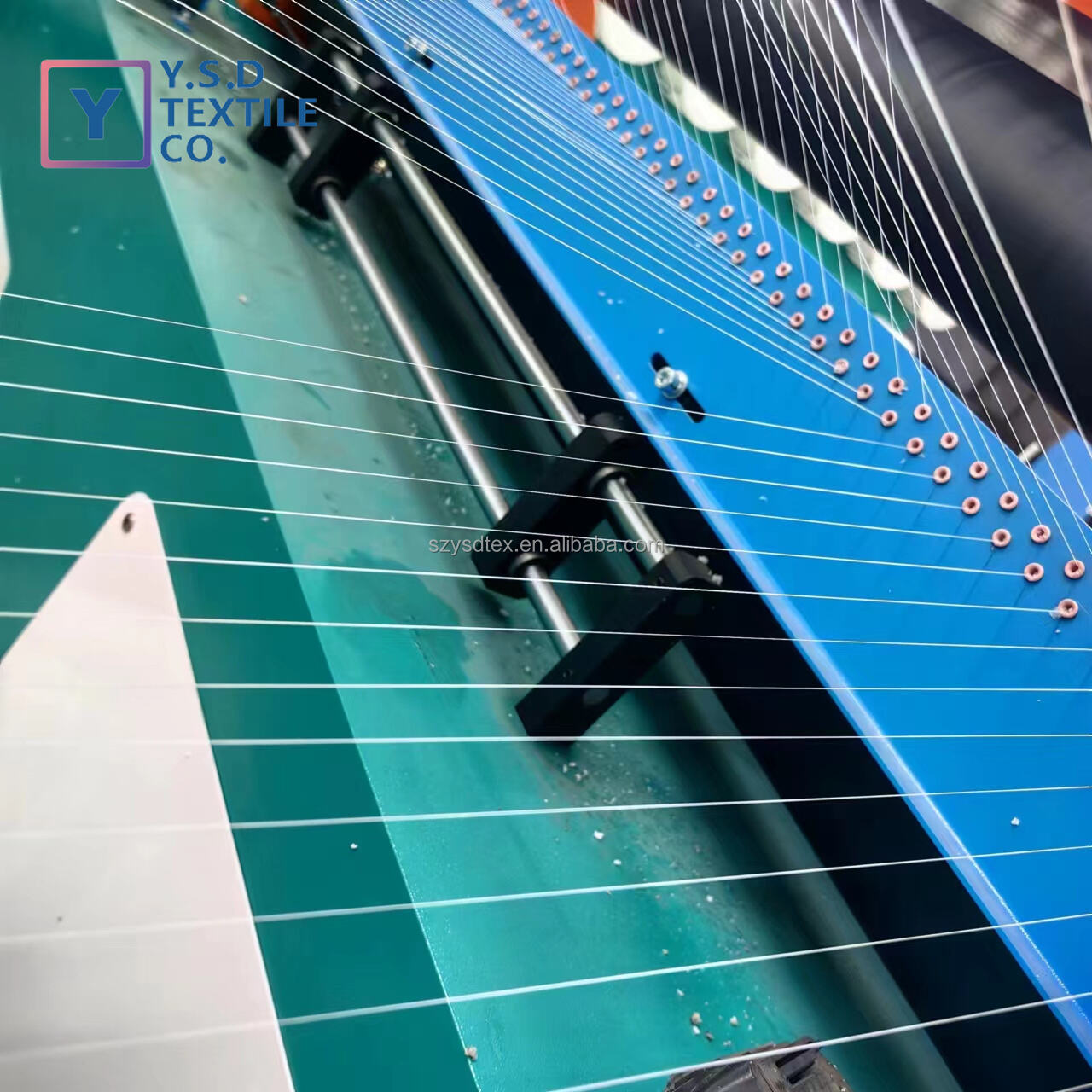

This machine is designed for fast and precise textile production, offering a maximum warping speed of 300m/min, which significantly reduces production time. It can handle a variety of materials, including cotton, wool, and synthetic fabrics. The device is equipped with a splitting warp feature that allows the user to produce fabrics with different patterns and thread counts, increasing the variety of products that can be created.

The YSD-M seamless knitting machine is equipped with an intuitive interface that makes it easy to operate. The control panel is straightforward, with a user-friendly interface that allows the operator to quickly adjust settings, such as the speed and thread count. This feature significantly increases productivity and efficiency by reducing the time required to prepare the machine between runs.

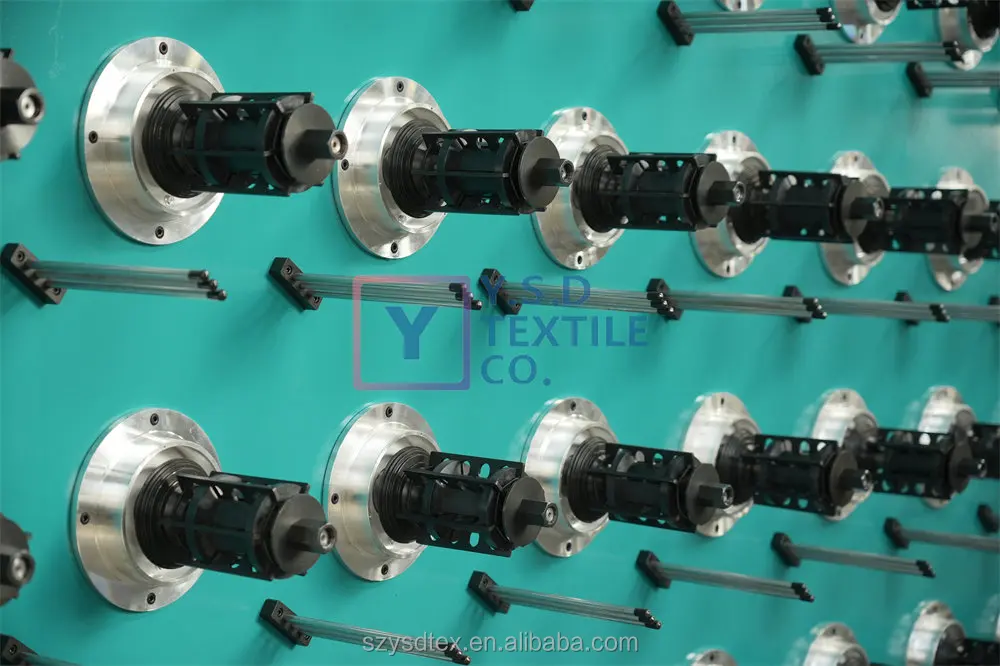

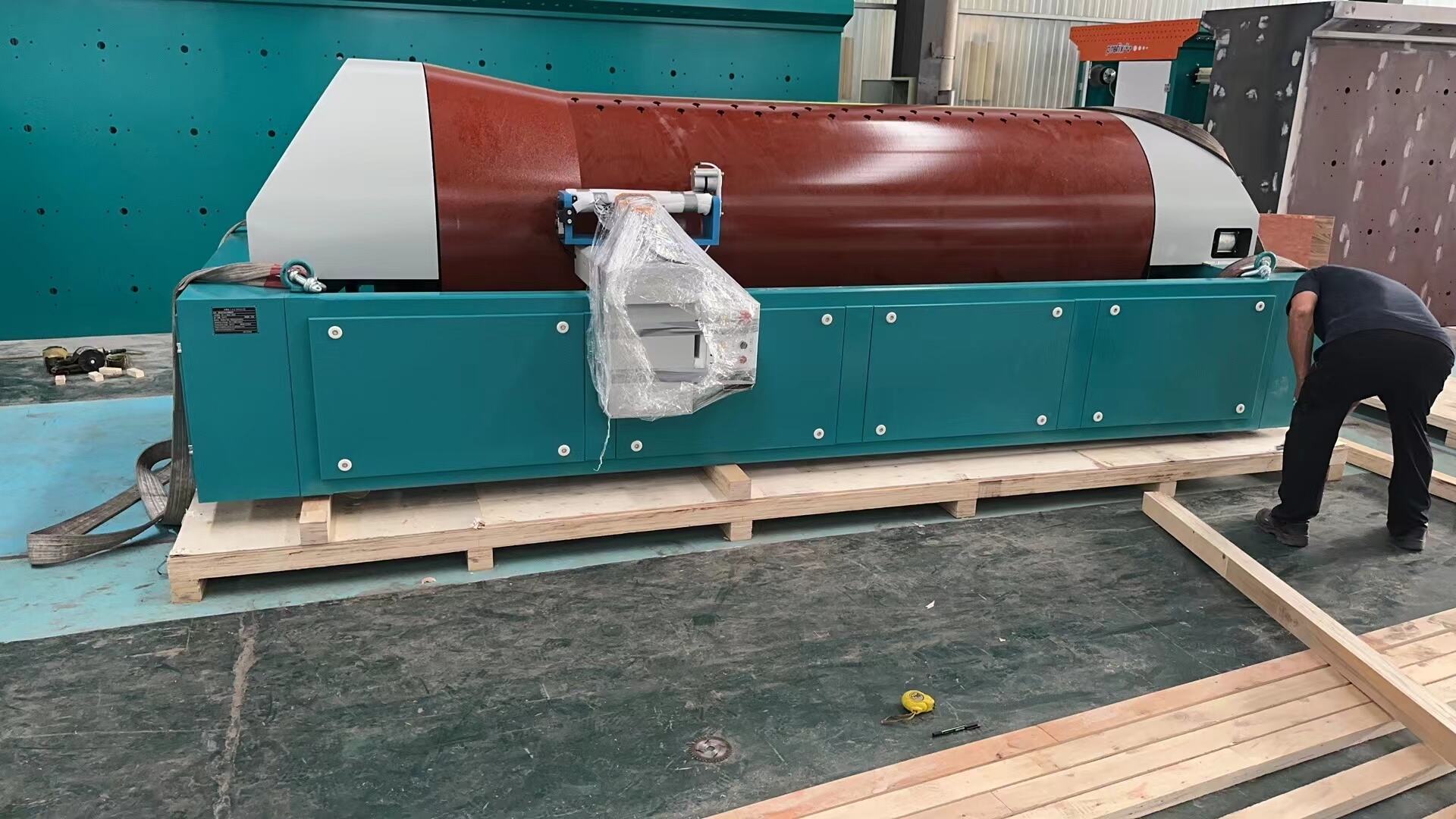

The yarn warping machine is built to last, ensuring reliability and durability over the years. The body is made of high-quality materials, providing long-lasting performance. The machine has a compact design, making it easy to install in small spaces. It occupies little floor space, and the design allows for easy maintenance and repair.

The cloth cutting machine is known for its precision, allowing operators to cut fabrics with a high degree of accuracy, ensuring consistent product quality and minimized waste levels. The splitting warp feature allows for the creation of unique patterns and designs, providing more options to the manufacturers and creative opportunities to designers.

ProfixM's YSD-M Mother Yarn Warping Knitting Machine Cloth Cutting Machine with Splitting Warp Feature is an excellent investment for any manufacturing plant looking to expand its textile production capabilities. The machine offers advanced features, durability, and fast production times, ensuring the manufacturer's quality and reputation. It is easy to use, requires minimal maintenance, and offers high precision, making it an excellent investment for long-term production needs

item |

value |

product |

MACHINE |

material capabilities |

NYLON/POLYESTER MOTHER YARN |

weight (kg) |

17000 |

machine type |

WARPING MACHINE |

video outgoing-inspection |

Provided |

machinery test report |

Provided |

core components |

Engine |

Place of origin |

China |

Jiangsu |

|

warranty |

1 Year |

Name |

splitting and Striping warping machine mother yarn warping machine |

Usage |

1t/day 240D/12F SD |

Warping max speed |

600m/min |

mother yarn tension |

0-500cn |

warping servo moto |

7.5kw |

beam moto |

15kw |

warp beam max speed |

250m/min |

displacement servo |

1.5kw |

Front roller servo |

5.5kw |

Back roller servo |

4.5kw |

1) The warping machine has the characteristics of high efficiency, stability, and reliability, which can greatly improve the production efficiency of the textile industry.

2) Its high precision and consistency ensure the quality of the fabric, making it more neat and uniform.

3) The warping machine is widely used in the textile industry and is one of the very important production equipment in textile factories

Q:How to place machines order

A:Please send us your purchase order by email, whatsapp or wechat. We need to know the following information for your order:

(1) Your products width and thickness(webbing, tapes, lace width and thickness)

(2) Price Item, Destination Port, Delivery time required

(3) Shipping information: Company Name, Address, Phone Number, Destination Seaport/Airport

Q:What are the payment terms

A:For orders, we can accept T/T, L/C at sight

Q:How many years of producing these machine

---We produced these machine for more than 15 years

EN

EN

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

RO

RO

RU

RU

ES

ES

ID

ID

UK

UK

VI

VI

TH

TH

TR

TR

BN

BN

NE

NE