A sectional warper is a vital machine in the textile industry, which is used to prepare yarn for weaving. The machine makes certain that the yarn is wound evenly on a beam, which then can be woven into fabrics.

One of the greatest advantages of using a sectional warper is that it makes the yarn preparation process more efficient. By winding up the yarn nice and even on the beam, the sectional warper helps to prevent tangles and breaks when you are ultimately weaving. The result is less time off line, greater productivity for textile producers. In addition, the sectional warpers allow different types and sizes of yarn to be used with them so that they are versatile and adaptable to various production requirements. This also makes it relatively easy for manufacturers to produce a different yarn type without the costly process of modifying machine settings. Also, the sectional warpers may be provided with additional features, such as automatic tension control and yarn break detection, leading to even higher quality and accuracy in the winding of yarn.

There are quite a few wholesale opportunities on the market for companies that want to invest in sectional warpers. Companies such as profixM have a large selection of sectional warpers in different price categories available, making the acquisition of production equipment more affordable. For companies buying several, sectional warpers an aggregated purchase results in volume pricing and special promotions, positively affecting each device’s price point as well as revenue earned. Moreover, wholesale buying often includes other value-added perks like the provision of longer warranties.

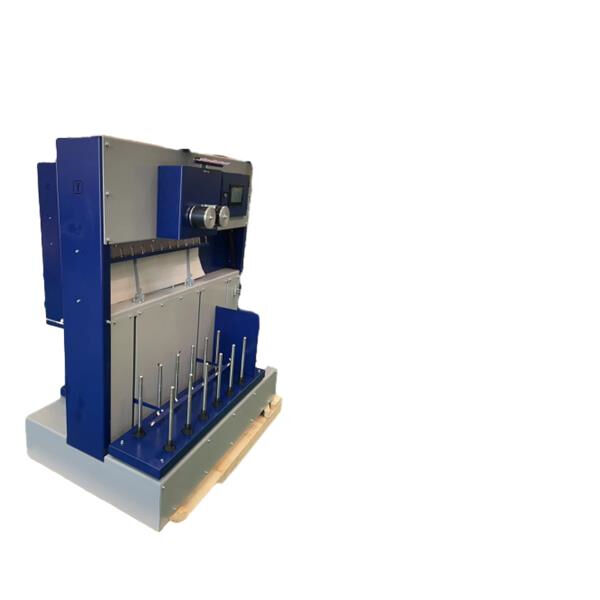

When you are searching to identify premium sectional warpers at competitive prices, then you should definitely check just profixM. We provide various sectional warpers which are highly durable and effective. You can purchase our products on-line via our website or for more information contact our customer service team. Selecting profix, you can also rely on the high quality of your sectional warper.

However, in the operation of sectional warpers there may also be problems that occur atypically. These problems may include tension problems, yarn breakages, and also alignment issues. It is necessary to maintain and check your sectional warper in order to resolve these issues. Ensure everything is well lubricated, tension adjusted and all in line. Should you have any troubleshootings, please refer to the user’s guide that came with this forma or customer service for help.

company was founded the year 2013. In the last eleven years, we've sold 300 sets of items remain the leading company in sales till today. company a Sectional warperfirm that designs, produces and sells split warping equipment and yarn. manufacturing team brimming with professional skills and experience.

have been providing yarn machines for more than 12 years. have top-quality research and development department. We constantly upgrade our Sectional warper. Also, have a 20,000m2 nylon/polyester manufacturing workshop. staff is committed to supplying machines of the best quality. Every member the team is extremely dedicated and accountable for all of their job. We are confident that efforts and technology will result in more efficient productive work.

factory team extremely customer-centric and knows that success of business is dependent on needs and satisfaction of its clients. Customers are Sectional warperlistened as well as production service are optimized meet customer expectations needs.

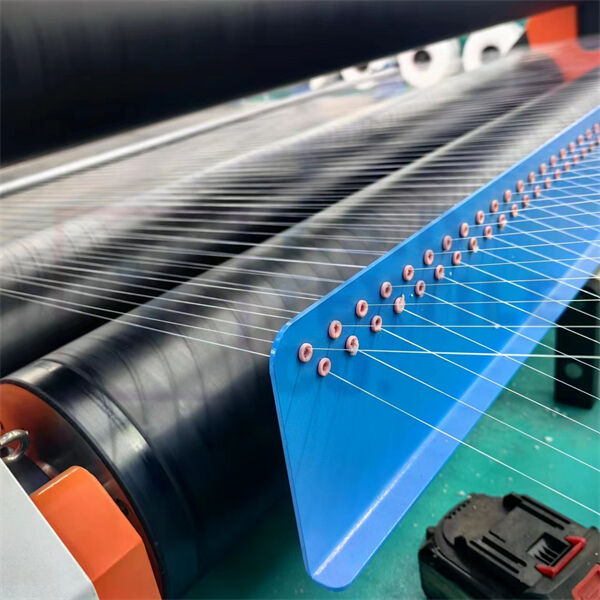

sectional mother-yarn splitting warping machine Sectional warperan same tension beam, with 550m/mins speed on nylon mother yarn.also created the first machine can make polyester dty mother yarn.products simple for installation, simple set up, and easy use and have minimal requirements on workers.